Sidewall direct venting, Installation & operation manual – Lochinvar KNIGHT XL 801 User Manual

Page 28

28

4

Sidewall direct venting

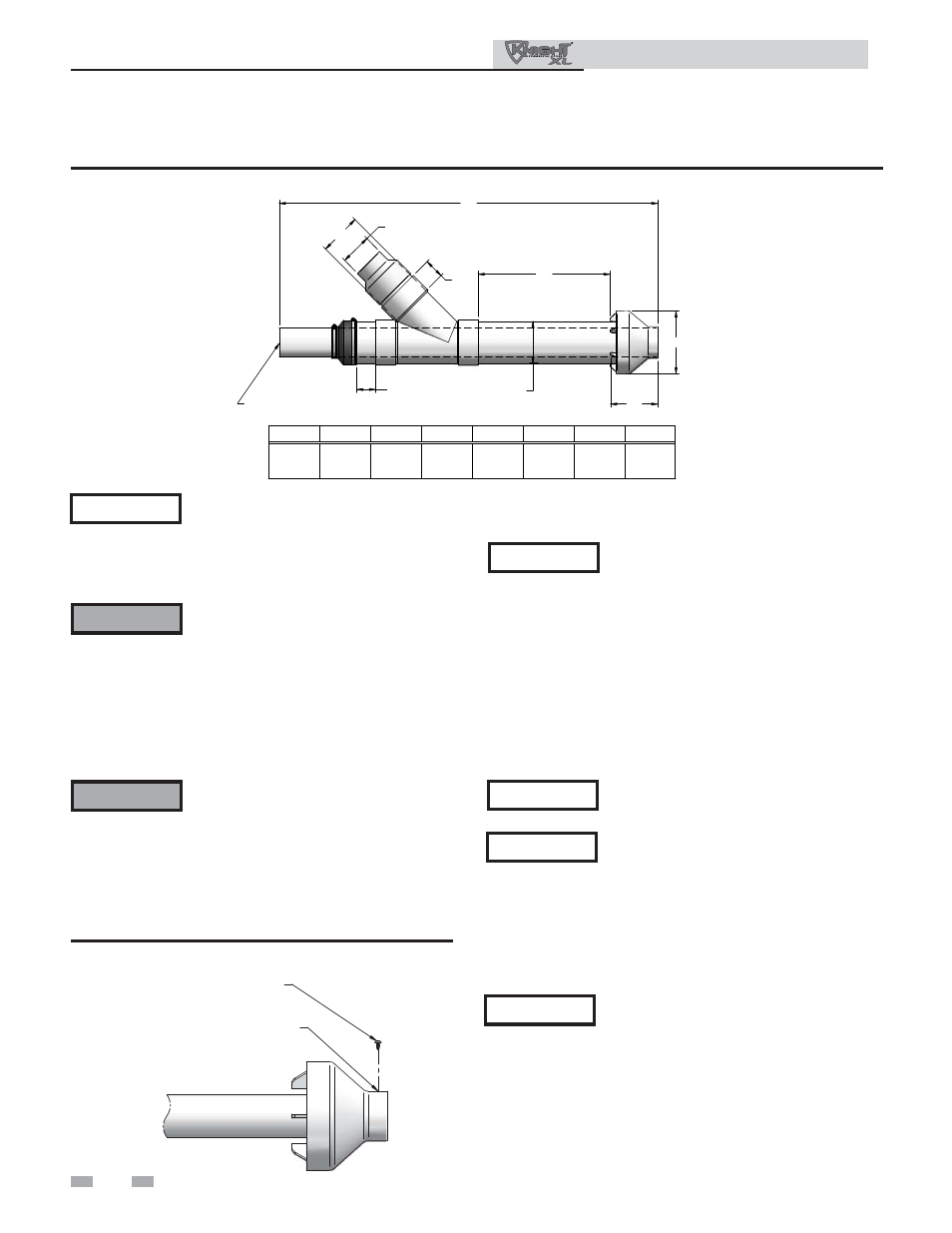

Sidewall termination – optional concentric vent: Models 400 - 601 Only

Figure 4-9 Concentric Vent Dimensional Drawing - Models 400 - 601

Instead of cementing the smaller pipe to

the rain cap, a fi eld-supplied stainless steel

screw may be used to secure the two (2)

components together when fi eld disassembly

is desired for cleaning (see FIG. 4-10).

When using the alternate screw assembly

method, drill a clearance hole in the rain

cap and a pilot hole in the vent pipe for

the screw size being used. Failure to drill

adequate holes may cause cracking of PVC

components, allowing combustion products

to be recirculated. Failure to follow this

warning could result in personal injury or

death.

Do not operate the appliance with the rain

cap removed or recirculation of combustion

products may occur. Water may also collect

inside the larger combustion air pipe and

fl ow to the burner enclosure. Failure to

follow this warning could result in product

damage or improper operation, personal

injury, or death.

STAINLESS STEEL SCREW

(FIELD SUPPLIED)

DRILL CLEARANCE HOLE IN

RAIN CAP & PILOT HOLE

IN VENT PIPE

Figure 4-10 Rain Cap to Vent Pipe Alternate Assembly

6. Install the Y concentric fi tting and pipe assembly through

the structure’s hole from an inside wall.

Do not allow insulation or other materials

to accumulate inside the pipe assembly

when installing through the hole.

7. Install the rain cap and small diameter pipe assembly

into the Y concentric fi tting and large pipe assembly

from an outside wall. Ensure small diameter pipe is

fastened tightly into the rubber adapter for #CVK3007

installations.

8. Secure the assembly to the structure as shown in

FIG. 4-11 using fi eld-supplied metal strapping or

equivalent support material.

Ensure termination location clearance

dimensions are as shown in FIG. 4-7.

If assembly needs to be extended to allow

sidewall thickness requirement, the two

(2) pipes supplied in the kit may be

replaced by using the same diameter,

fi eld-supplied standard schedule 40 PVC

for CVK3007. Do not extend dimension

D* more than 60 inches (1524 mm) (see

FIG. 4-9).

NOTICE

ƽ WARNING

ƽ WARNING

NOTICE

NOTICE

NOTICE

If assembly depth needs to be reduced,

dimension D can be as short as possible.

NOTICE

"B" DIA. PVC

VENT / EXHAUST

"A"

"H" DIA.

"D"

"E"

"F"

"G"

3"

(76 MM)

A

B

C

D

E

F

G

H

60"

4"

6"

21 1/8"

10"

7 5/8"

3"

6 5/8"

"C" DIA.

"B" DIA.

(1524 MM)

(102 MM)

(152 MM)

(537 MM)

(254 MM)

(194 MM)

(76 MM)

(168 MM)

Installation & Operation Manual