Vertical direct venting, Alternate vertical concentric venting – Lochinvar KNIGHT XL 801 User Manual

Page 34

34

5

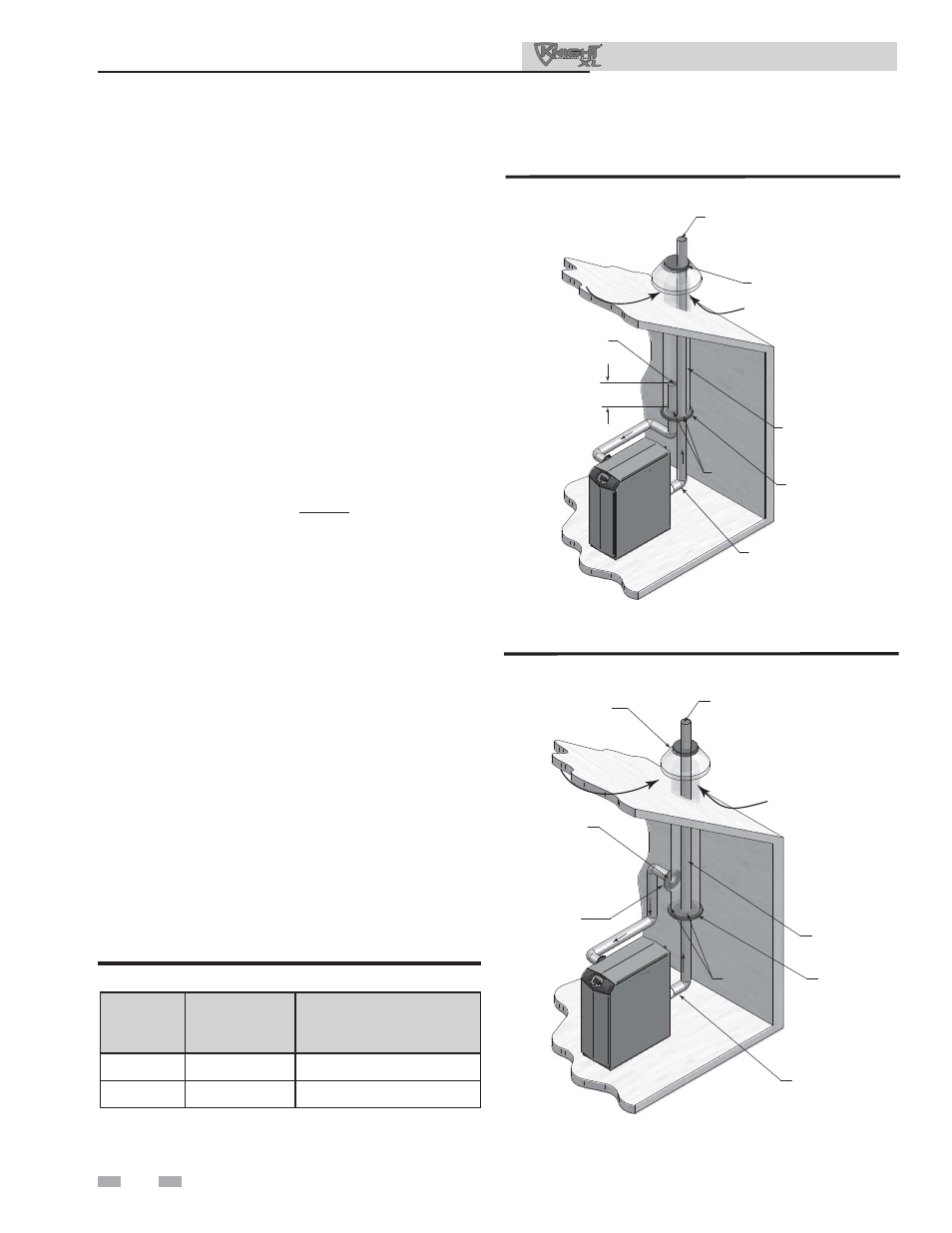

Vertical direct venting

Alternate vertical concentric venting

This appliance may be installed with a concentric vent

arrangement where the vent pipe is routed through an

existing unused venting system; or by using the existing

unused venting system as a chase for vent and combustion

air routing.

Concentric Venting Arrangement

The venting is to be vertical through the roof. The annular

space between the O.D. of the vent pipe and the I.D. of the

existing unused venting system is utilized for the combustion

air source.

The minimum size of the existing vent system required to

achieve enough annular space for combustion air can be

found in Table 5A.

The upper and lower termination as well as any other unsealed

joints in the existing vent system must be sealed to ensure that

all combustion air is drawn from under the vent cap as shown

in FIG.’s 5-8 and 5-9.

Approved venting materials must be used as specifi ed in

Table 3A on page 18.

Follow all vent / air termination and clearance requirements

per this section to the appropriate example. Installation must

comply with local requirements and with the National Fuel

Gas Code.

The maximum allowable equivalent vent and air intake

lengths for this venting arrangement are to be determined

from the General Venting Section.

If an existing unused venting system is converted for use

with this method of concentric venting, the installer must

ensure that the existing venting system is clean and free from

particulate contamination that will harm this appliance and

cause increased nuisance calls or maintenance. See Table 1A

on page 11 for a list of corrosive contaminants and sources.

Two example scenarios of a concentric venting arrangement

are shown for illustrative purposes in FIG.’s 5-8 and 5-9.

Figure 5-8 Concentric Vent Example 1

12"

MIN.

FLUE EXHAUST

AIR INLET

W/ SCREEN

FLUE OUTLET

SEALED

CAP

EXISTING

SEAL

SEAL

COMBUSTION AIR

*For concept illustration only. Individual installations

may vary due to job site specifi c equipment.

Figure 5-9 Concentric Vent Example 2

FLUE EXHAUST

AIR INLET

W/ SCREEN

FLUE OUTLET

SEALED

CAP

EXISTING

SEAL

SEAL

COMBUSTION AIR

SEAL

*For concept illustration only. Individual installations

may vary due to job site specifi c equipment.

Model

Vent / Air

Inlet Size

Minimum Existing

Vent / Chase Size

400 - 601

4"

7"

701 - 801

6"

10"

Table 5A Alternate Vertical Concentric Vent / Chase Sizes

Installation & Operation Manual