Operating information – Lochinvar KNIGHT XL 801 User Manual

Page 64

64

11

Operating information

Outdoor reset operation, if used

Target temperature with outdoor reset

This feature improves the system’s effi ciency as the outdoor

temperature warms up.

See the Knight XL Service Manual to change the settings.

Reset curve

The reset curves look at outdoor air temperature and adjusts

the set points.

Cascade

When multiple boilers are installed, they can be wired

together in a cascade sequence. A maximum of eight boilers

can be controlled from a single control. In this application

one boiler would be designated as the Leader control and all

others would be designated as Member controls. If installing

the boilers in an existing system, the new boilers should

be programmed as the Leader and/or the higher number

addresses. The Leader control can be programmed to use

Lead/Lag or Effi ciency Optimization control methods.

Once the Leader boiler receives a call for heat from a room

thermostat, BMS, or Modbus, the control will determine what

the set point will be. If outdoor air reset is desired, connect

the outdoor air sensor to the terminals on the Low Voltage

Connection Board on the Leader boiler. The set point will be

calculated based on the programmed reset curve parameters.

See the Knight XL Service Manual to program the reset curve.

If outdoor air reset is not desired, do not connect the outdoor

air sensor. A fi xed temperature set point can be programmed

into the control. See page 59 of this manual to program the

set point.

If the water temperature at the system supply sensor is less

than the set point + the turn-off offset - the off-on differential,

then the control will initiate a call for heat on the Cascade

(see the Knight XL Service Manual for an explanation of

the offset and differential). The Leader will energize the lead

boiler on the Cascade. For a new startup this will be the

Leader boiler.

DHW, Night Setback, and Ramp Delay operation with

cascade

For normal mode DHW operation any boiler(s) in the Cascade

can be selected to provide heat for a DHW call. Select a boiler to

be designated as the DHW boiler. Connect the DHW thermostat

or sensor to the terminals on the Low Voltage Connection

Board marked for the corresponding device. When the boiler

receives a DHW call, the Leader control will take that boiler

out of the Cascade sequence. If another boiler is available, the

Leader will start it up to take its place.

The DHW boiler will adjust its set point to the programmed

DHW set point and will adjust its fi ring rate to maintain this.

Once the DHW call has been satisfi ed, the Leader control will

place that boiler back into the Cascade sequence.

Switching of the boiler between DHW operation and SH

operation when there is a call for both does not occur in Cascade

Mode.

When DHW is programmed for Zone Mode, connect the DHW

thermostat or tank sensor to the Leader boiler. When a DHW

call is received, the Leader will modulate the entire Cascade to

bring the system supply temperature up to the DHW boiler set

point (if higher).

Night Setback operation of the boilers within the Cascade is

available. Programming of the Night Setback will be done

through the Leader boiler. Refer to the Knight XL Service

manual for information regarding Night Setback.

Ramp Delay operation of the boilers as described in the Knight

XL Service Manual is available when the boilers are part of a

Cascade system.

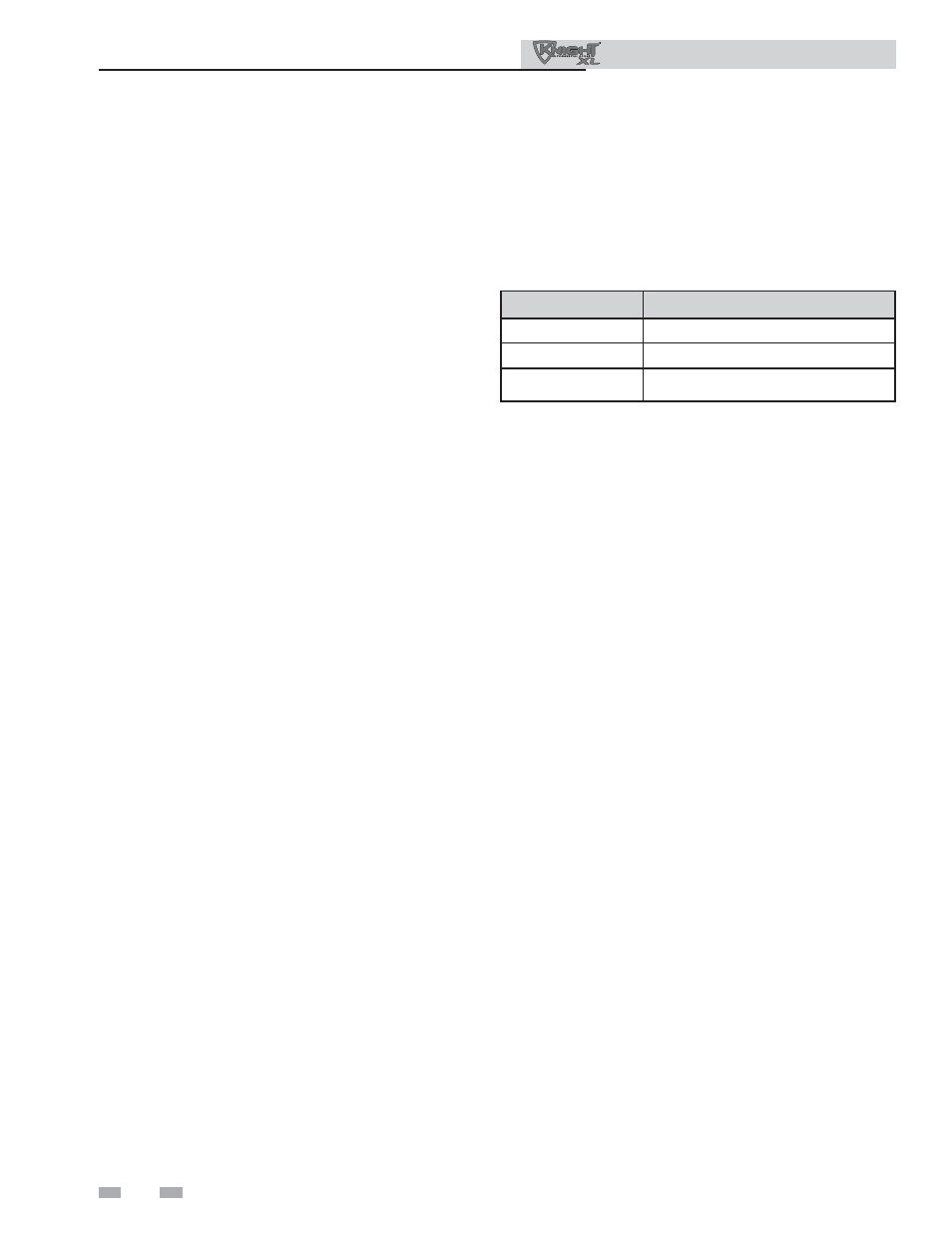

Sequence of the cascade

To equalize the run time of all boilers on the Cascade, the fi ring

sequence will automatically be changed at set intervals.

For the fi rst 24 hours after initializing the Cascade, the sequence

will be changed every hour. After that the sequence will be

changed once every 24 hours. The switching on/off sequence

will be as follows:

DAY

SWITCHING ON SEQUENCE

Day 1

L-M1-M2-M3-M4-M5-M6-M7

Day 1 + 1 hour

M1-M2-M3-M4-M5-M6-M7-L

Day 1 + 2 hours

M2-M3-M4-M5-M6-M7-L-M1

If a boiler is used to heat an indirect DHW tank, it will

automatically be given the lowest priority.

Low water cutoff protection

1. The SMART SYSTEM control module uses temperature

sensing of both supply and return areas of the heat

exchanger. If the fl ow rate is too low or the outlet

temperature too high, the control module modulates and

shuts the boiler down. This ensures boiler shutdown in

the event of low water or low fl ow conditions.

2. Some codes and jurisdiction may accept these integral

features of the control in lieu of requiring an additional

limit control or low water cutoff. Consult local jurisdiction

to determine. A low water cutoff is available from the

factory (WTR20009).

Installation & Operation Manual