Hydronic piping – Lochinvar KNIGHT XL 801 User Manual

Page 38

6

Hydronic piping

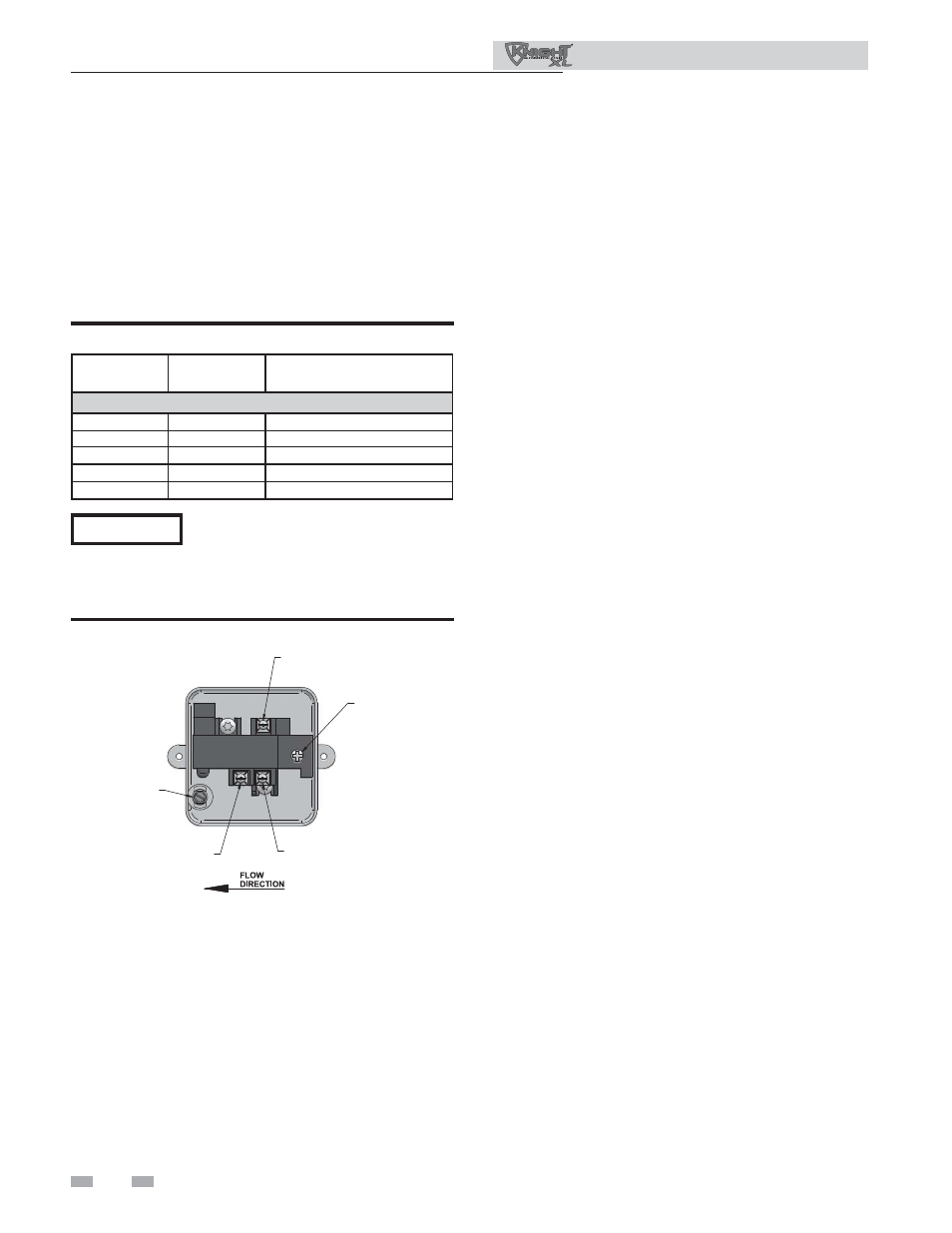

Figure 6-3 Flow Switch Adjustment

Flow switch adjustment

Refer to Table 6A for the proper setting of the sensitivity

screw. For reference, the position of the screw prior to setting

should be turned clockwise with a Phillips driver until it stops

(FIG. 6-3). Proceed to turn the screw counterclockwise the

amount of turns listed in Table 6A based on the model.

Consult the manufacturer’s instructions for wiring the fl ow

switch to your system.

NORMALLY

OPEN

SENSITIVITY

ADJUSTMENT

NORMALLY

CLOSED

COMMON

GROUND

NOTICE

Turn the sensitivity screw clockwise to

increase the fl ow rate required to activate

the switch. Turn the sensitivity screw

counterclockwise to decrease the fl ow rate

required to activate the switch.

MODEL

PADDLE SIZE

SENSITIVITY SCREW

ADJUSTMENT

Note: Paddles are included with the fl ow switch.

400

#3

7½ turns

501

#3

5½ turns

601

#3

7¼ turns

701

#3

5¼ turns

801

#3

3¼ turns

Table 6A Paddle Size / Sensitivity Screw Adjustment

Near boiler piping components

1. Boiler system piping:

Boiler system piping MUST be sized per the pipe

requirements listed in Table 6B. Reducing the pipe size

can restrict the fl ow rate through the boiler, causing

inadvertent high limit shutdowns and poor system

performance. Flow rates are based on 20 feet (6 m) of

piping, 4 - 90° elbows, and 2 - fully ported ball valves.

2. Boiler system circulating pump:

Field supplied. The boiler circulating pump should be

based on 20 feet (6 m) of piping, 4 - 90° elbows, and

2 - fully ported ball valves.

3. Domestic hot water circulating pump:

Field supplied. The pump MUST be sized to meet

the

specifi ed minimum fl ow requirements listed in

FIG.’s 6-5 and 6-6. Consult the indirect water heater

operating guide to determine fl ow characteristics for the

selected product used.

4. Variable speed boiler system circulator:

Knight boilers are capable of controlling a variable

speed boiler system circulator. Variable speed circulators

MUST be sized to meet the specifi ed minimum fl ow

requirements listed in FIG.’s 6-5 and 6-6 on page 40 at

full

speed.

5. Boiler

isolation

valves:

Field supplied. Full port ball valves are required. Failure

to use full port ball valves could result in a restricted fl ow

rate through the boiler.

6. Check

valves:

Field supplied. Check valves are recommended for

installation as shown in FIG.’s 6-7 through 6-11. Failure

to install check valves could result in a reverse fl ow

condition during pump(s) off cycle.

7. Domestic indirect hot water isolation valves:

Field supplied. Full port ball valves are required. Failure

to use full port ball valves could result in a restricted fl ow

rate through the boiler.

8. Anti-scald mixing valve:

Field supplied. An anti-scald mixing valve is

recommended when storing domestic hot water above

115°F

(46°C).

9. Unions:

Field supplied. Recommended for unit serviceability.

10. Temperature and pressure gauge:

Factory supplied. The temperature and pressure gauge is

shipped loose. It is the responsibility of the contractor to

install the temperature and pressure gauge on the boiler

water

outlet.

11. Pressure relief valve:

Factory supplied. The pressure relief valve is sized to

ASME

specifi cations.

38

Installation & Operation Manual