Hydronic piping, Installation & operation manual – Lochinvar KNIGHT XL 801 User Manual

Page 42

42

6

Hydronic piping

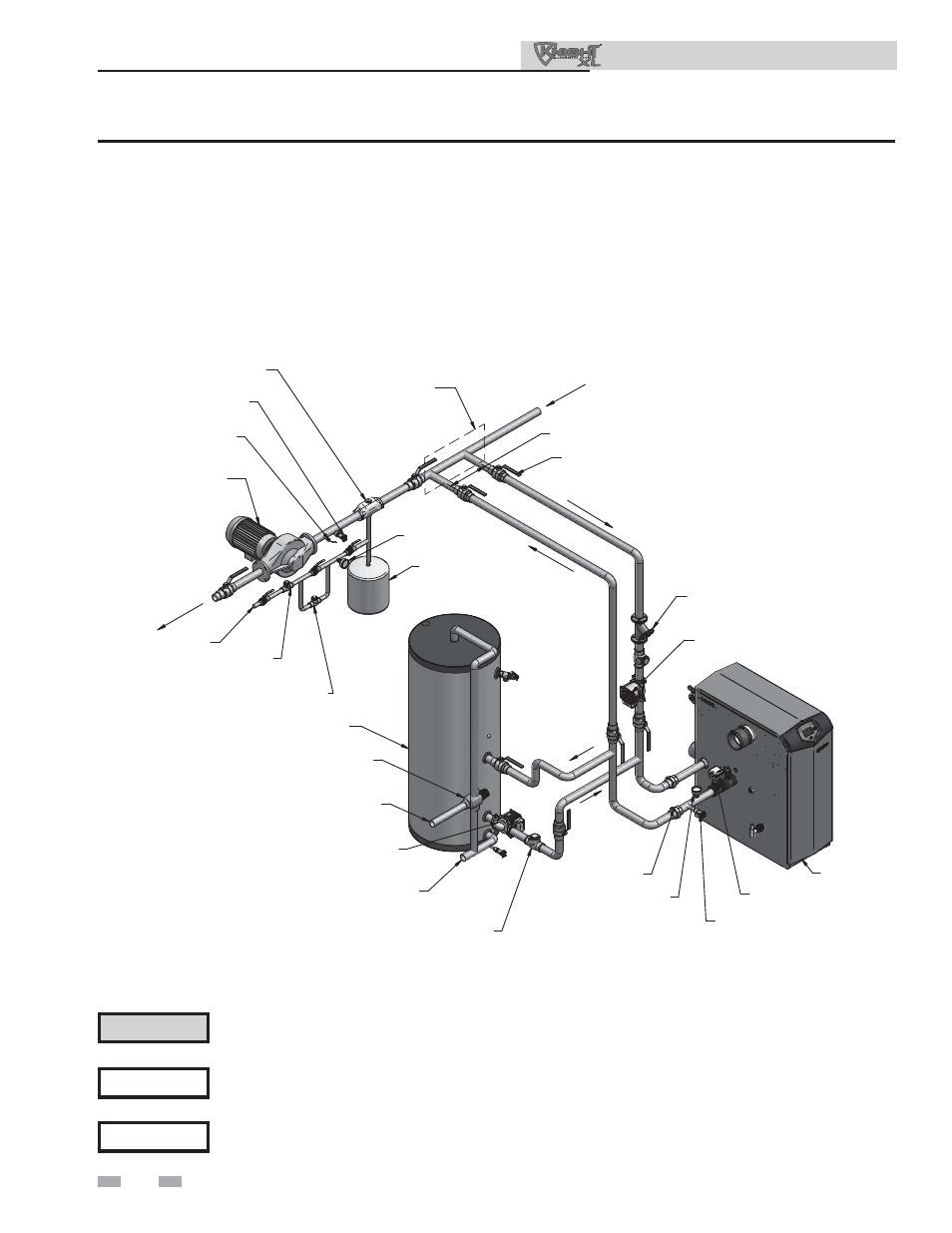

EXPANSION TANK

AIR SEPARATOR

PRESSURE REDUCING

VALVE

BACK FLOW

PREVENTER

BALL VALVE

(TYPICAL)

UNION (TYPICAL)

PRESSURE RELIEF

VALVE

FLOW CHECK

VALVE (TYPICAL)

INDIRECT DHW

TANK

BOILER

TEMPERATURE / PRESSURE

GAUGE

PRESSURE GAUGE

DRAIN

DRAIN POINT

(TYPICAL)

BOILER CIRCULATOR

COLD WATER IN

ANTI-SCALD

MIXING VALVE

SYSTEM SUPPLY SENSOR

(WHEN USED)

SYSTEM CIRCULATOR

TO

SY

ST

EM

FR

OM

SY

ST

EM

DOMESTIC

HOT WATER

CIRCULATOR

HOT WATER OUT

MAKE UP WATER

NOT TO EXCEED 4 PIPE DIA OR MAX. OF 12" APART

Y-STRAINER

(RECOMMENDED)

MAY SUBSTITUTE

LOW LOSS HEADER

Figure 6-8 Single Boiler - Primary/Secondary Piping

NOTICE

System fl ow should always remain higher than the required fl ow for the boiler(s) when the boiler(s) is in

operation to prevent short cycling and high limit issues.

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

NOTICE

CAUTION

Indirect water heaters are capable of transferring a limited number of Btu’s into the water. Ensure boiler

output does not not exceed indirect water heater transfer capabilities.

Installation & Operation Manual