Installation instructions – Sanyo CHDZ09053 User Manual

Page 48

2-38

Design of W-3WAY ECO-i SYSTEM Unit Specifi cations

1

2

3

4

5

6

7

8

4. Installation Instructions

4-12. Prepare the Tubing

Material: Use C1220 phosphorous deoxidized copper as described in JIS H3300, “Copper and Copper Alloy Seamless Pipes

and Tubes.” (For tubes that are ш1" (ш25.4 mm) or larger, use 1/2H material or H material. For all others use O material.)

Tubing size

Use the tubing size indicated in the table below.

When cutting the tubing, use a tube cutter, and be sure to remove any burrs.

(The same applies to distribution tubing (optional).)

When bending the tubes, bend each tube using a radius that is at least 4 times the outer diameter of the tube.

When bending, use suffi cient care to avoid crushing or damaging the tube

For fl aring, use a fl are tool, and be sure that fl aring is performed correctly.

CAUTION

Use sufficient caution during preparation of the tubing. Seal the tube ends by means of caps

or taping to prevent dust, moisture, or other foreign substances from entering the tubes.

Refrigerant tubing (Existing tubing can be used.)

Tubing size (mm)

Outer dia.

Thickness

Outer dia.

Thickness

ш1/4" (ш6.35)

t1/32" (t0.8)

ш3/4" (ш19.05)

over t5/128" (t1.0)

ш3/8" (ш9.52)

t1/32" (t0.8)

ш7/8" (ш22.22)

t5/128" (t1.0)

ш1/2" (ш12.7)

t1/32" (t0.8)

ш1-1/8" (ш28.58)

t5/128" (t1.0)

ш5/8" (ш15.88)

t5/128" (t1.0)

ш1-3/8" (ш34.93)

t3/64" (t1.1)

1

2

3

4

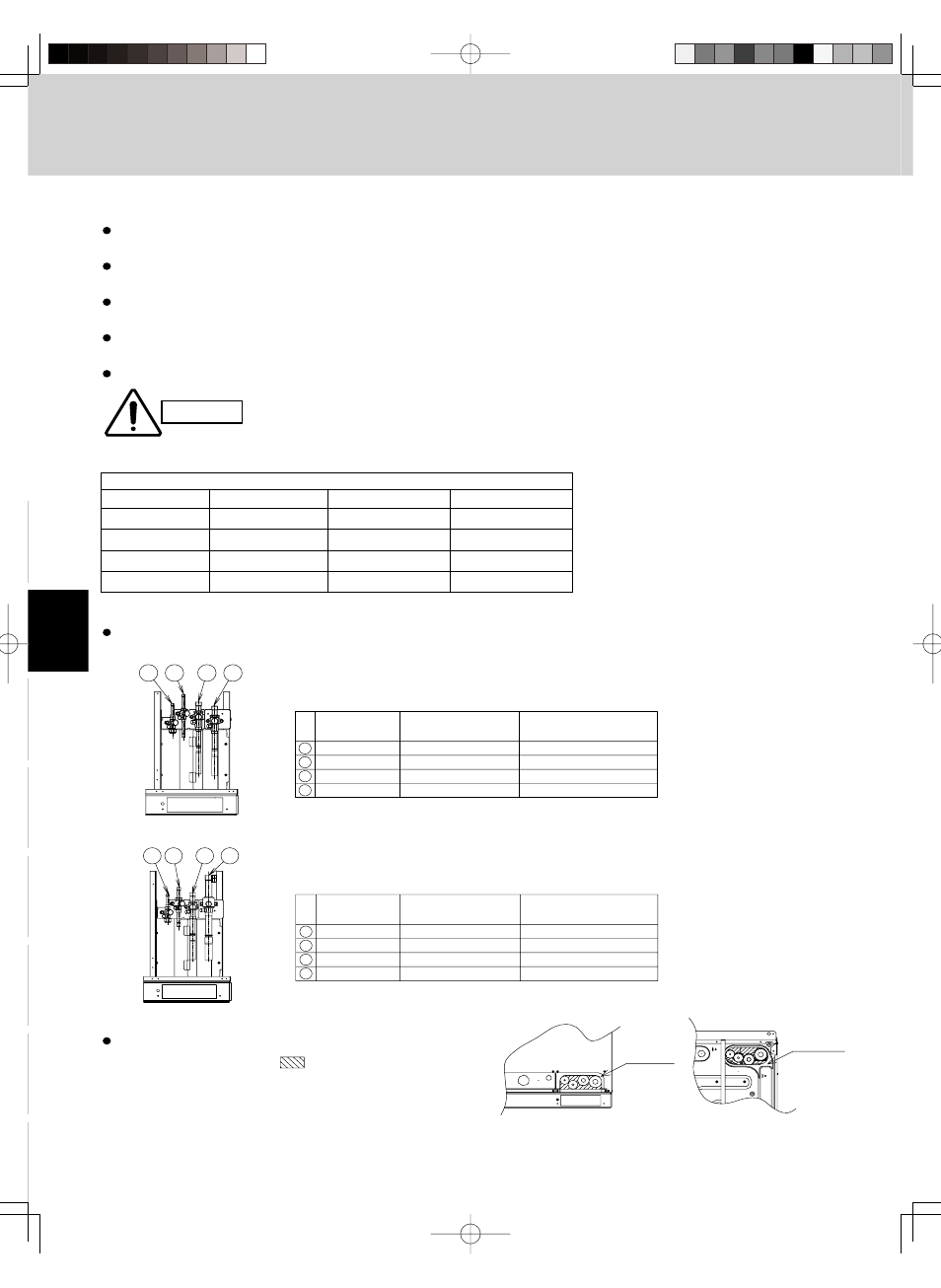

09053 type (10 horsepower)

1

2

3

4

Refrigerant

tubing

Connection method

Use supplied

connector tube?

Suction tube

Brazed connection

Brazed connection

Brazed connection

Flared connection

Yes (ø3/4"

m ø7/8")

Yes (ø5/8"

m ø3/4")

Discharge tube

Balance tube

Liquid tube

No

No

1

2

3

4

014053 type (16 horsepower)

1

2

3

4

Refrigerant

tubing

Connection method

Use supplied

connector tube?

Suction tube

Brazed connection

Brazed connection

Brazed connection

Flared connection

Discharge tube

Balance tube

Liquid tube

Yes (ø1"

m ø1"–1/8")

Yes (ø3/4"

m ø7/8")

No

No

Refrigerant tube port

Use caulking, putty, or a similar material to fi ll any gaps

at the refrigerant tube port (

) in order to prevent

rainwater, dust or foreign substances from entering the

unit.

* Perform this work even if the tubing is routed out in a

downward direction.

Tubing

cover

Base plate

Tubing routed out forward

Tubing routed out downward

4-13. Connect the Tubing

Use the supplied connector tubing. (See fi gure below.)