Replacement decals and information plates, Important adjustment procedures, Ref. part. no. number description – Scag Power Equipment STR User Manual

Page 81

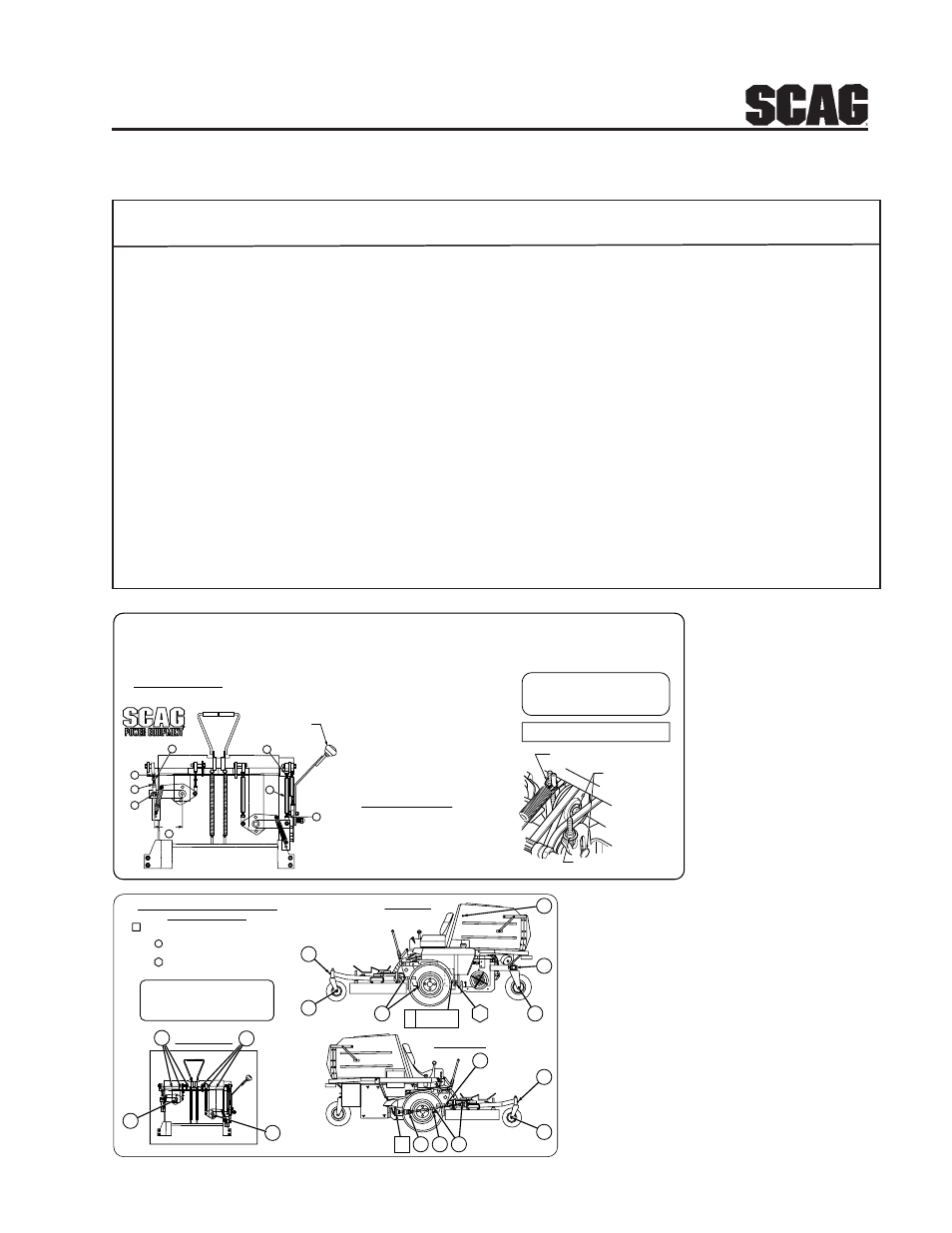

35

Ref. Part.

No. Number Description

1

48071

Decal, Danger - Spinning Blades

2

481040

Decal, Warning - Rotating Blades

3

48072

Decal, Heavy Duty Commercial

4

48404

Decal, Metalcraft - Made in USA

5

48656

Decal, Patent

6

48318

Decal, 48

7

48314

Decal, Scag

8

481377

Decal, Danger - Rotating Blower Blades

9

481272

Decal, Fuel Tank

10

481378

Decal, Caution/Danger - Thrown Objects

11

481239

Decal, Instrument Panel - Upper

12

481493

Decal, Cutting Height

13

481348

Decal, Instrument Panel - Lower

14

481350

Decal, Dump Valve

15

481349

Decal, R.H. Fender

16

481427

Decal, Seat Base

17

481595

Decal, Grease Points

REPLACEMENT DECALS AND INFORMATION PLATES

R

Right transmission

belt adjusting nut

481427

Speed control

lever

E

H

F

G

A

4-1/2"

J

D

IMPORTANT ADJUSTMENT PROCEDURES

READ OPERATOR'S MANUAL FOR MORE DETAILS

IMPORTANT!:

Do not overfill. Room for hot

fluid expansion must be allowed

or resulting expansion may cause

leaks in the system.

ALL gearbox Lubricant:

Mobil SHC630

Check hydraulic fluid level daily

while fluid is cool. Fluid level

should be 2-1/4" below top of filler

neck. Fill with SAE 20W50 motor oil only.

HYDRAULIC TANK FLUID LEVEL

Left transmission

belt adjusting nut

Loosen nut before

adjusting belt.

Tighten after the

belt is adjusted.

Check tire pressure -

( Drive tires - 15 PSI , All others - 25 PSI )

NEUTRAL ADJUSTMENT

Adjust distance ( B ) from LH ball j oint

to pivot to 4 - 1 / 2 " .

1.

Loosen jam nuts (D & E). With an operator

in the seat, engine running, speed control

lever in neutral and the parking brake

disengaged-rotate turn buckle (H) until the

machine begins to creep forward on RH

side. Back of 1/2 turn, tighten jam nuts

( D & E ). Repeat for lH side, leave jam

nuts ( F & G ) loose for step # 3.

Move the speed control lever so the machine

creeps forward. If the machine pulls to the

left, rotate turnbuckle ( J ) CCW. If the

machine pulls to the right, rotate turnbuckle

( J ) CW. Return to neutral with keyswitch

off. Tighten jam nuts ( F & G ).

TRACKING ADJUSTMENT

If the machine does not track straight through

all speeds, loosen nut (A) on LH pump

linkage. If the machine pulls to the right,

move outward in slot to slow wheel. If the

machine pulls to the left, move inward in slot

to speed up left wheel. Re-adjust neutral

starting with step # 2.

2.

3.

B

16

IMPORTANT

GREASE BLOWER

BEARINGS WEEKLY

LITHIUM MP WHITE GREASE 2125

UNDER SEAT

GREASE FITTING LUBRICATION

LUBRICANT / INTERVAL

LITHIUM MP WHITE GREASE 2125

40 HOURS / WEEKLY

CHASSIS GREASE

100 HOURS / BI - MONTHLY

CHASSIS GREASE

200 HOURS / MONTHLY

RIGHT SIDE

LEFT SIDE

481595

11

11

1

9

5

9

4

3

5

4

3

5

12

BLOWER

BEARINGS

7

6

8

10

10

2

17