Scag Power Equipment STR User Manual

Page 44

38

Section 7

B. Blade Sharpening

-NOTE-

If possible, use a file to sharpen the blade.

Using a wheel grinder may burn the blade.

-NOTE-

DO NOT sharpen the blades beyond 1/3 of

the width of the blade.

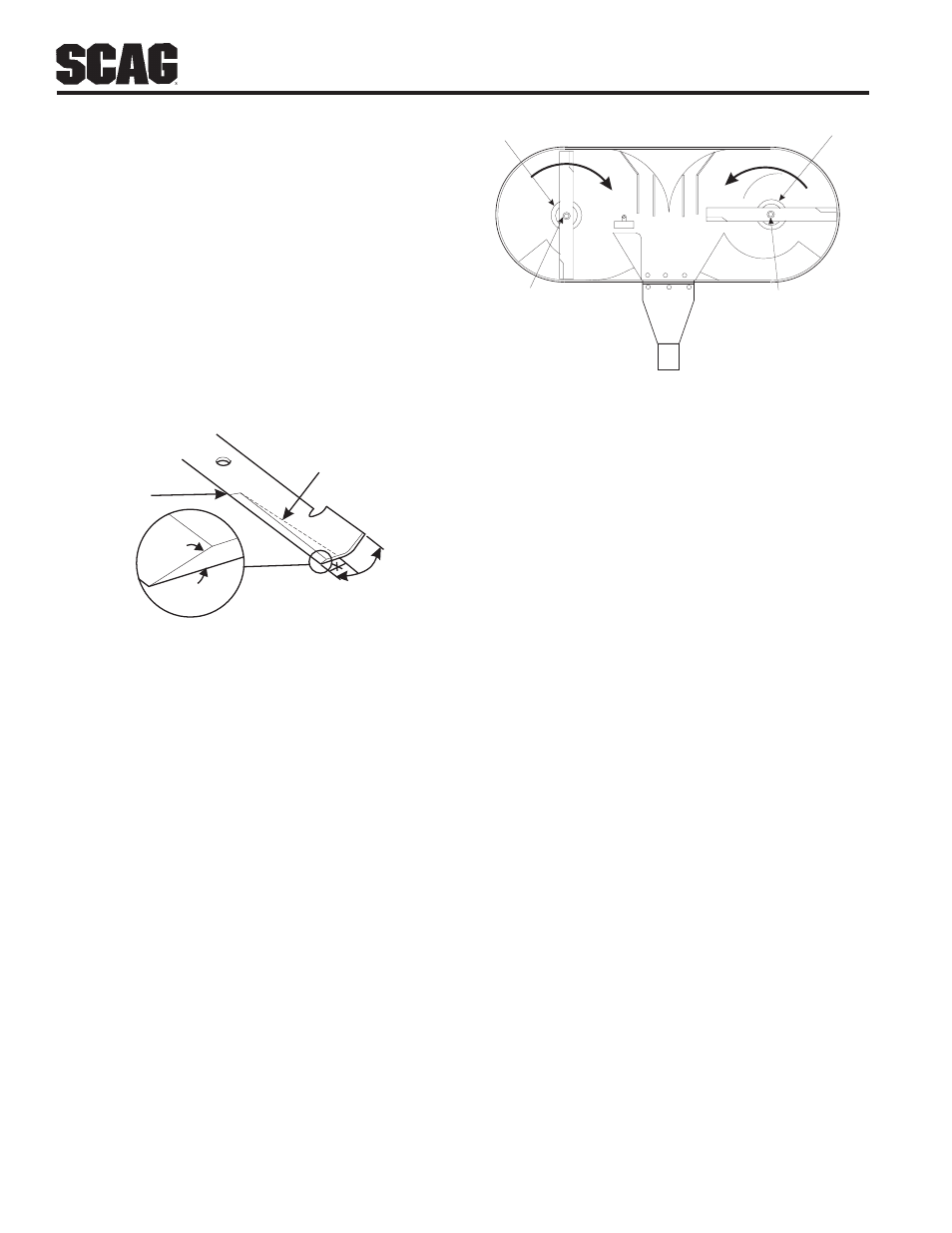

1. Sharpen the cutting edge at the same bevel as the

original. See Figure 7-9. Sharpen only the top of the

cutting edge to maintain sharpness.

30°

30°

X Must NOT Exceed

1/3 Blade Width

Angle Blade Back

Do Not Cut In

Figure 7-9 Blade Sharpening

2. Check the balance of the blade. If the blades are out

of balance, vibration and premature wear can occur.

See your authorized Scag dealer for blade balancing

or special tools, if you choose to balance your own

blades.

C. Blade Replacement

1. Remove the ignition key before replacing the blades.

2. Tilt the mower deck and secure in place using the two

prop rods.

3. Using the Blade Buddy accessory, remove the

attaching bolt, lockwasher, flatwasher and the spacer.

Remove the cutter blade and blade drive adapter from

the spindle shaft. (Figure 7-10).

4. Remove the cutter blade from the blade drive adapter

by removing the (2) two # 10-32 X 1/2" socket head

capscrews, elastic stop nuts and spacers.

Attaching Hardware

Bolt, Lockwasher and

Flatwasher

Attaching Hardware

Bolt, Lockwasher and

Flatwasher

Blade Adapter

Blade Adapter

-IMPORTANT-

Do not interchange the blades. There is a

left and a right cutting blade. Be sure to

install the blades correctly or the mower will

not cut properly.

-IMPORTANT-

The blade must be installed 90° to each other

as shown in Figure 7-10. If the blades are

not installed as shown, they will contact each

other and could cause severe damage to the

blades, deck, and blade drive system.

4. To install the cutter blade, position it on the blade

drive adapter and secure using the #10-32 X 1/2"

socket head capscrews, spacers and elastic stop nuts.

Install the cutter blade and blade drive adapter

assembly to the spindle shaft using the flatwasher,

lockwasher, spacer and bolt. Tighten the bolt to a

torque of 150 ft-lb.

7.10 TIRES

Check the tire pressures after every 8 hours of operation

or daily.

Caster Wheels ......................................... 25 PSI

Rear Wheel ............................................. 25 PSI

Drive Wheels .......................................... 15 PSI

Figure 7-10 Blade Replacement