Scag Power Equipment STR User Manual

Page 36

30

Section 7

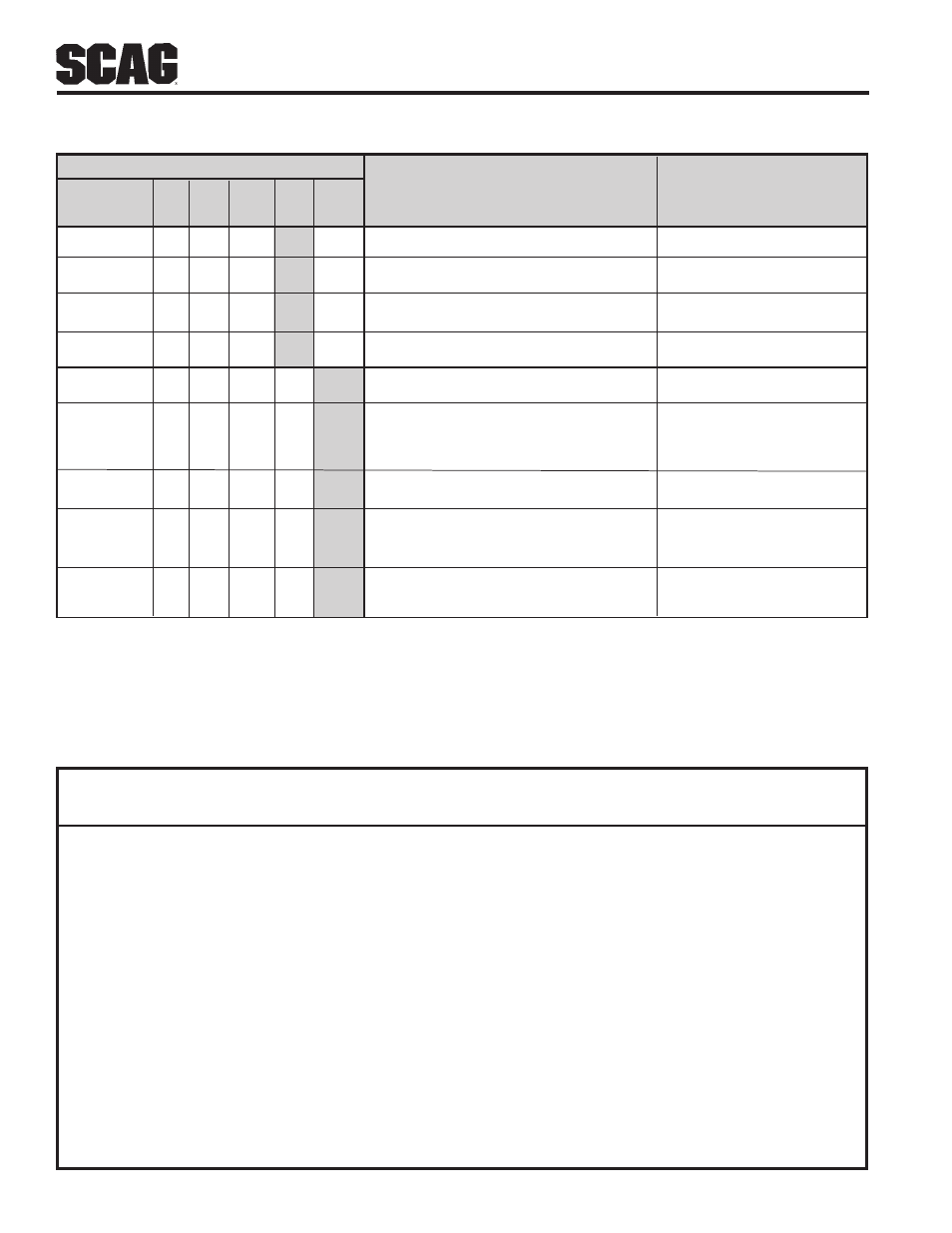

MAINTENANCE CHART - RECOMMENDED SERVICE INTERVALS (CONT'D)

HOURS

Break-In

8

40

100 200 500

Procedure

Comments

(First 10)

X

Apply grease to fittings

See paragraph 7.2

X

Check hardware for tightness

X

Change engine oil filter

See paragraph 7.4

X

Check hydraulic oil level

See paragraph 7.3

X

Replace engine fuel filter

See paragraph 7.5

X

Drain hydraulic system and

See paragraph 7.3

replace hydraulic oil

Use SAE 20W50

Motor Oil

X

Replace hydraulic oil filter

See paragraph 7.3

X

Replace transmission gearbox

See paragraph 7.12

lubricant

X

Replace lubricant in cutter deck

See paragraph 7.13

gear boxes

* Perform these maintenance procedures more frequently under extreme dusty or dirty conditions

7.2 LUBRICATION

GREASE FITTING LUBRICATION CHART

(SEE FIGURE 7-1)

LUBRICATION

NO. OF

LOCATION

INTERVAL

LUBRICANT

PLACES

1.

Drive Shaft Mtg. Spindle

40 Hours/Weekly

+Lithium MP White Grease 2125

1

2

Blower Bearings

8 Hours/Daily

+Lithium MP White Grease 2125

1

3

Caster Wheel Pivot

100 Hours/Bi-Weekly

Chassis Grease

2

4

Caster Wheel Bearings

100 Hours/Bi-Weekly

Chassis Grease

2

5

Cutter Deck Push Arms

100 Hours/Bi-Weekly

Chassis Grease

2

6

Rear Wheel Pivot

100 Hours/Bi-Weekly

Chassis Grease

1

7

Rear Wheel Bearings

100 Hours/Bi-Weekly

Chassis Grease

1

8

Hopper Discharge Pivot

100 Hours/Bi-Weekly

Chassis Grease

1

9

Cutter Deck Drive Shaft

100 Hours/Bi-Weekly

Chassis Grease

3

10

Steering Control Levers and Linkage

100 Hours/Bi-Weekly

Chassis Grease

6

11

Speed Control Levers

100 Hours/Bi-Weekly

Chassis Grease

2

12

Engine Belt Idler Arm

200 Hours/Monthly

Chassis Grease

1

13

Blower Belt Idler Arm

200 Hours/Monthly

Chassis Grease

1

14

Blower Gate Lever

200 Hours/Monthly

Chassis Grease

1