Intake air connection – State Industries SHE50-100PE User Manual

Page 7

5

Servicing should only be performed by a Qualified Service Agent

factory supplied/installed fittings

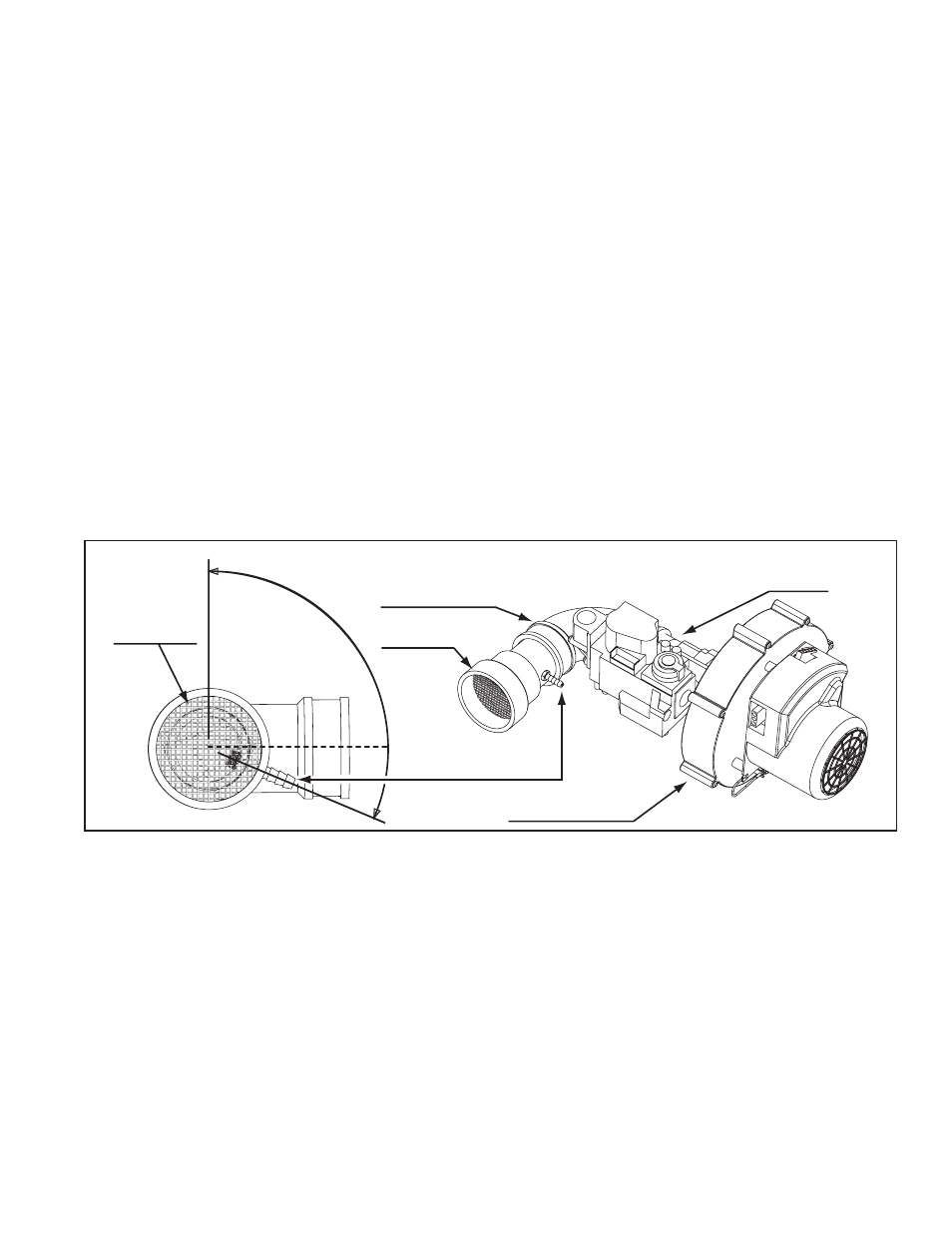

Factory supplied vent and intake air terminations and factory installed fittings on the water heater are not

factored in to the vent and intake air pipe equivalent feet calculations. The intake air connection fitting and

exhaust elbow (vent connection) are factory installed fittings, see Figure 1 below and Figure 3 on page 8.

intaKe air connection

The intake air connection has a screen and a hose barb installed at the factory, see Figure 1 below.

The intake air connection screen is installed to prevent debris from entering the Combustion Blower and/or

Burner. This screen is left in place when the water heater is installed in a Power Vent configuration but must

be removed before connecting the intake air piping on direct Vent installations. once the intake air pipe is

installed the screen, if not removed, would be hidden from view and may become clogged with debris over

time. This can cause poor combustion and Blocked Air Intake fault conditions and Control System lock outs.

Ensure this screen has been removed on all direct Vent installations if experiencing Blocked Air Intake fault

conditions.

The hose barb is installed on the intake air connection to connect the Blocked Intake Air switch sensing tube.

The intake air connection is factory installed so that the hose barb is at approximately a 115° angle when

viewed from the end. Ensure the hose barb is not oriented any lower than 115° as this will allow water from

condensate or snow being drawn inside the intake air piping on direct Vent installations to fill the Blocked

Intake Air switch sensing tube. If water does enter the Blocked Intake Air switch sensing tube it will damage

the switch and cause Blocked Air Intake fault conditions and Control System lock outs. Ensure this hose

barb is properly oriented when experiencing Blocked Air Intake fault conditions. Angles between 90° and

115° are acceptable. If necessary loosen the hose clamp on the intake air connection elbow and rotate the

intake air connection fitting to adjust the angle properly as shown in Figure 1 below.

HOSE BARB

ANGLED

BETWEEN

90° AND 115°

HOSE BARB FITTING FOR

BLOCKED INTAKE AIR

SWITCH SENSING TUBE

COMBUSTION BLOWER

INTAKE AIR CONNECTION

24 VOLT

GAS VALVE

INTAKE AIR

CONNECTION

INTAKE AIR

CONNECTION ELBOW

INTAKE AIR

CONNECTION

SCREEN MUST

BE REMOVED

ON DIRECT VENT

INSTALLATIONS

Figure 1

Service Notes:

• Plastic debris left on the edges of intake air pipe sections after cutting must be removed on direct Vent

installations. These debris can collect inside and clog the Burner which can cause poor combustion,

sooting, rough starting, rough operation and Ignition Failure fault conditions and Control System lock

outs. The Burner is a radial design that can trap debris, see Figure 5 on page 9.

• Exceeding the equivalent length limitations for the vent piping will cause Blocked Exhaust fault

conditions and Control System lock outs.

• Exceeding the equivalent length limitations for the intake air piping will cause Blocked Air Intake fault

conditions and Control System lock outs.

• Exceeding the maximum number of elbows allowed for the intake air and/or vent piping will also cause

Blocked Air Intake and Blocked Exhaust fault conditions and Control System lock outs.

• using smaller intake air and/or vent pipe than required for the installed equivalent length will also cause

Blocked Air Intake and Blocked Exhaust fault conditions and Control System lock outs.