Flame sensing current test – State Industries SHE50-100PE User Manual

Page 21

19

Servicing should only be performed by a Qualified Service Agent

flame sensing current test

during the heating cycle the flame sensing current is normally between 8.0 μA and 12.0 μA with a clean

Flame Sensor. over time the Flame Sensor will accumulate corrosion (rust) and this will reduce flame sensing

current. With heavier use, more heating cycles/greater load, corrosion will occur more quickly.

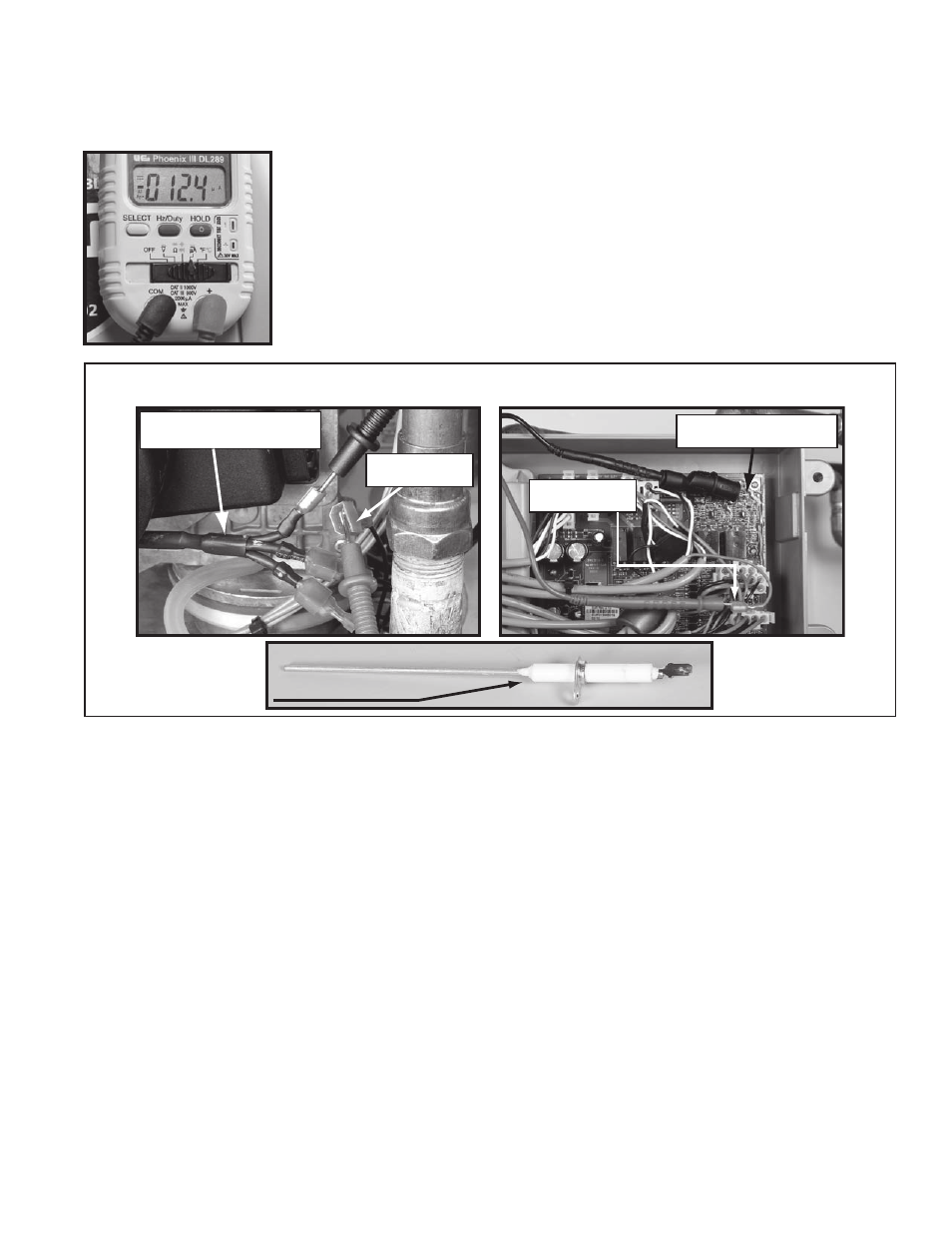

Measuring flame sensing current requires a test meter with a dC micro amp

function, see Tools Required on page 2. The meter’s selector is set to dC micro

amps. The two test leads from the meter are placed in series with the flame sensing

circuit. This can be done at the spade (male/female) wiring connectors behind the

CCB enclosure or at the J4 spade connection on the CCB circuit board. See Figure

19 below and the CCB Circuit Board Layout on page 41.

To measure flame sensing current turn off power to the water heater and connect

the test meter following one of the two methods shown in Figure 19. Restore power

and ensure a call for heat is active - when the Control System energizes the 24 Volt

Gas Valve the meter will measure flame sensing current during normal operation.

FLAME SENSOR

CERAMIC INSULATOR

FLAME SENSING TEST BEHIND

THE CCB ENCLOSURE

FLAME SENSING TEST INSIDE

THE CCB ENCLOSURE

CCB J4 FLAME SENSOR

CONNECTION

IGNITER/FLAME SENSOR

WIRING HARNESS FROM CCB

WIRE FROM

FLAME SENSOR

WIRE FROM

FLAME SENSOR

Figure 19

Service Notes:

• The Flame Sensor wire behind the CCB is one of three wires in a harness that also serves the Igniter.

Ensure you have identified the correct wire before performing a flame sensing test to prevent damage to

the test meter. A female spade connector is used at the end of the wring harness from the CCB for the

Flame Sensor, two male connectors are used for the Igniter.

• The most common cause of Ignition Failure lock out is a corroded Flame Sensor. Rust/corrosion

will accumulate on the Flame Sensor over time. The Flame Sensor should be inspected and cleaned

anytime the measured flame sensing current is below 8 µA or the Burner has been removed. Clean

the Flame Sensor with ultra fine steel wool. do noT use a coarse abrasive material such as sand

paper. Inspect the ceramic insulator on the Flame Sensor for cracks, replace the Flame Sensor if it

is damaged. The Combustion Blower and Burner must be removed to access the Flame Sensor, see

Combustion Blower and Burner Removal on page 14.

• An open flame sensing circuit caused by disconnected or loose connectors can also cause ignition

failure. Check the spade connector behind the CCB enclosure and check all wiring and wiring

connections between the Flame Sensor and the J4 connector on CCB circuit board, see CCB Circuit

• The Burner not being grounded will cause Ignition Failure - see Electrical Requirements on page 6 and

Figure 16 on page 17. Ensure the water heater and the Burner are properly grounded.