Igniter, Igniter current test – State Industries SHE50-100PE User Manual

Page 22

20

Servicing should only be performed by a Qualified Service Agent

igniter

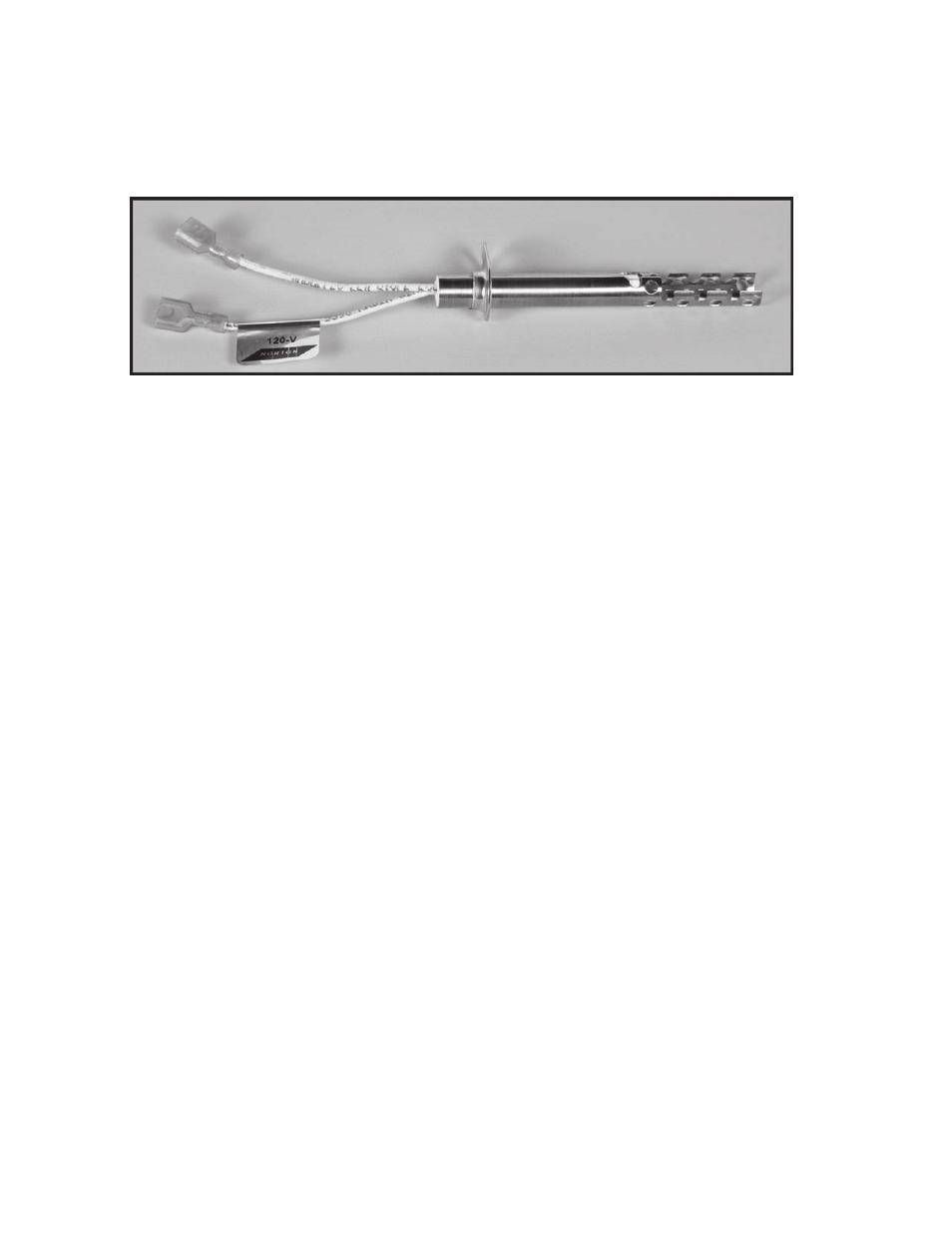

The water heaters covered by this manual use a hot surface igniter (HSI). The Igniter is made of a ceramic

composite material, see Figure 20 below. The Control System powers the Igniter (120 VAC) from the J5

Socket on the CCB. The Control System monitors amperage through the Igniter to ensure it is hot enough to

ignite the fuel gas flowing to the Burner during ignition. The amount of Igniter amperage is proportional to its

heat output; the higher the amperage is, the higher the surface temperature of the Igniter will be.

Figure 20

The Control System is programmed to verify a minimum of 0.5 AC amps during the Igniter Warm up operating

state, see operating States on page 48. If the current does not reach 0.5 amps during warm up the Control

System will lock out and display Low Igniter Current fault condition on the LCd. See the Sequence of

operation on page 54.

Igniters are wearing parts, over time hot surface igniters will wear out and must be replaced as they will no

longer generate enough heat to cause ignition. The life of the Igniter is directly tied to usage; the number

of heating cycles. Consider rasing the differential setting to reduce the number of heating cycles if frequent

Igniter failure occurs, see operating Set Point And differential Adjustment on page 49.

With age and wear the resistance of the Igniter, measured in ohms, will rise. As the resistance rises the

electrical current flowing through the Igniter decreases and so does the Igniter's surface temperature. new

Igniters will generally measure between 90 and 120 ohms at 77° F (25° C). The acceptable resistance for an

Igniter should be less than 200 ohms. Measuring resistance is a useful test to verify if the Igniter is no longer

working at all; IE: if the measured resistance is an open circuit, infinite ohms, the Igniter must be replaced.

However, the resistance of the Igniter varies with temperature and with the test meter being used. Because

of these variables the most reliable field test is to measure current during the Igniter Warm up operating state

to verify Igniter current is above the Control System's required minimum of 0.5 AC amps.

igniter current test

1. using a clamp style amp meter, clamp the jaws of the amp meter around one of the two Igniter wires at

the J5 Socket on the CCB or behind the CCB enclosure where the wiring harness from the CCB connects

to the Burner Adapter wiring harness. See CCB Cover Removal And Replacement on page 40, CCB Circuit

Board Layout on page 41 and Figure 21 on page 21.

2. Ensure a call for heat is active, raise the operating Set Point or dump water at a nearby fixture.

3. Ensure the desktop Screen is visible on the Control System's LCd, see desktop Screen on page 46.

4. Record Igniter amperage during the Igniter Warm up operating state. The Combustion Blower speed will

noticeably reduce just before the Igniter is energized and a animated lighting bolt Status Icon appears on

the desktop Screen, see Status Icons on page 47.

5. If the Igniter current is less than 0.5 or zero amps, check all wring and connections between the J5

Socket on the CCB and the Burner Adapter wiring harness behind the CCB. Turn off power and check the

resistance to the Igniter at the two Igniter wires from the Burner Adapter wiring harness behind the CCB.

Ensure the two Igniter wires are used for this test, the Igniter wires from the Burner Adapter will both be

"female" spade connectors. If it is an open circuit, infinite resistance, remove the Combustion Blower and

Burner Assembly to inspect the Igniter and the Burner Adapter wiring harness. Replace the Igniter and/

or Burner Adapter wiring harness if necessary. See Combustion Blower and Burner Removal on page 14.