Brake inspection & replacement – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 84

-82-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

S E R V I C E

Brake Inspection &

Replacement

The linkage geometry on this lathe is non

adjustable. Before replacing the brake shoes,

verify that all fasteners are tight, and all clevis

pins and yokes have minimal wear. As pivot

points wear, the increased slop in the linkage

absorbs the usable stroke that is required for full

brake application. If the brake does not stop the

lathe as fast as it should, before replacing the

brake shoes, verify that the linkage is not worn

and is the cause of the problem.

Tools Needed:

Qty

Another Person .................................................... 1

Hex Wrench 6mm ................................................. 1

Hex Wrench 8mm ................................................. 1

Needle-Nose Pliers ................................................ 1

Basic Caliper ........................................................ 1

Safety Glasses ...................................................... 1

Respirator Rated for Brake Dust ........................ 1

To replace the brake shoes:

1.

DISCONNECT LATHE FROM POWER!

2.

Put on a respirator and eye protection to

protect yourself from hazardous brake dust.

3.

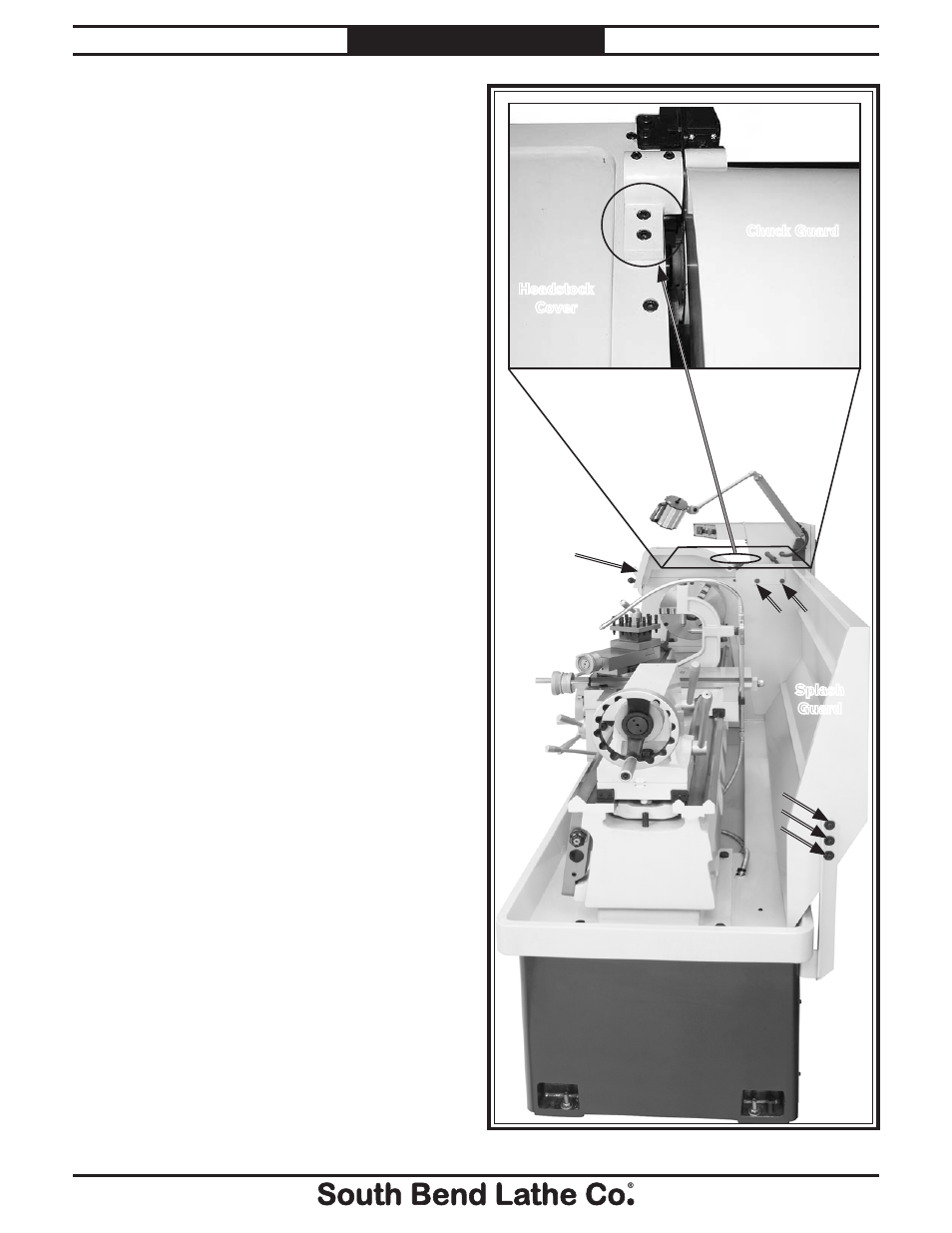

With the help of another person, remove the

splash guard, which is attached with the five

capscrews shown in Figure 147.

4.

Once the splash guard is removed, remove

the two chuck guard mount cap screws

(Figure 147) and the chuck guard from the

headstock cover.

Figure 147. Tailstock end splash guard fasteners.

Splash

Guard

Chuck Guard

Headstock

Cover

Chuck

Guard