Connecting to power – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 26

-24-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

P R E P A R A T I O N

Connecting to Power

Due to the complexity required for planning,

bending, and installing the conduit necessary for

a code-compliant hardwire setup, an electrician

or other qualified person MUST perform this

type of installation. Hardwire setups typically

require power supply wires to be enclosed inside

of a solid or flexible conduit, which is securely

mounted at both ends with the appropriate

conduit fittings. All work must adhere to the

required electrical codes.

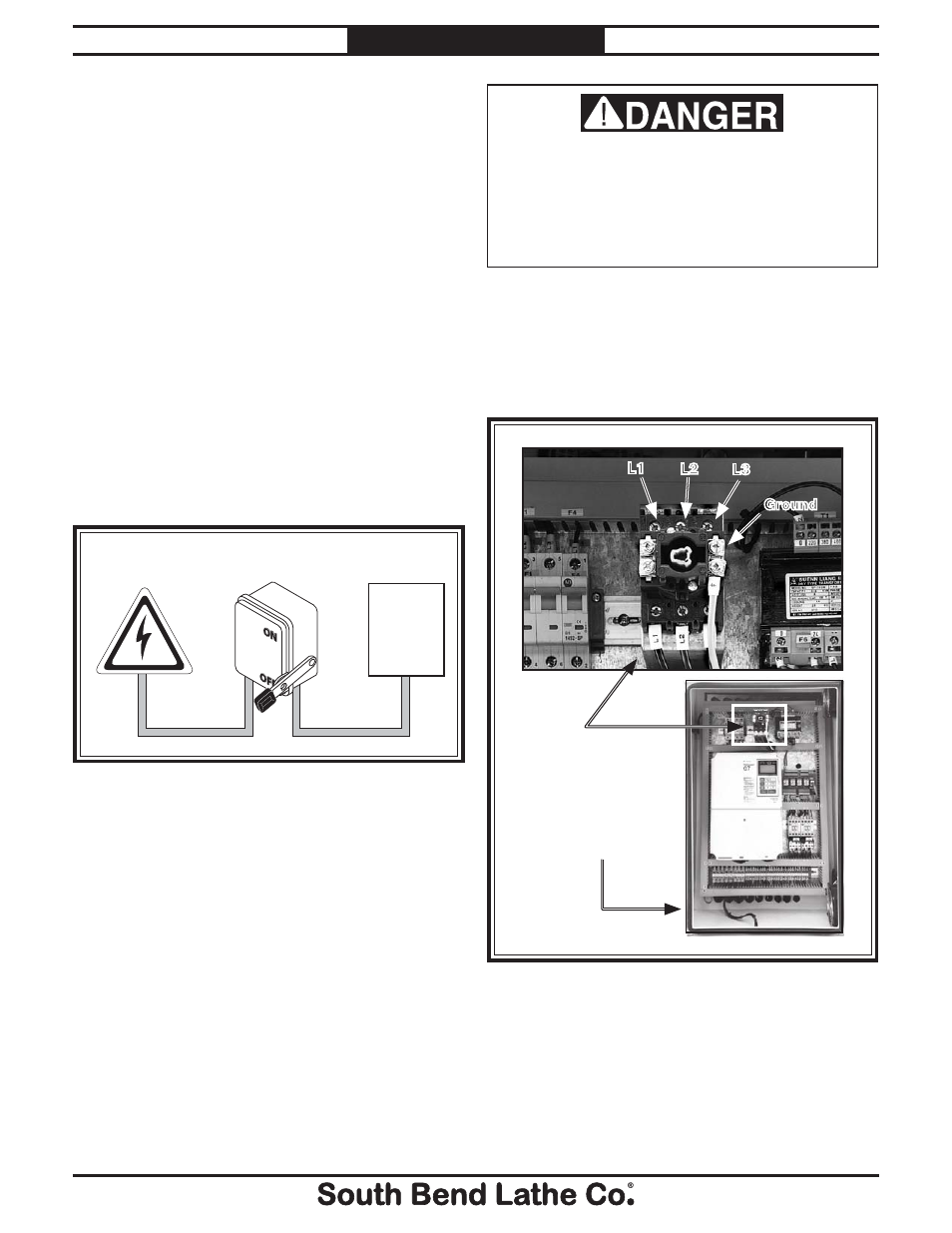

The hardwire setup for this machine must

include a locking disconnect switch (see Figure

15) between the power source and the machine.

This switch serves as the means to completely

disconnect the machine from power to prevent

electrocution accidental startup during

adjustments, maintenance, or service to the

machine.

Power Source

Locking

Disconnect Switch

Machine

Conduit

Conduit

Figure 15. Typical hardwire setup with a locking

disconnect switch.

The incoming power wires must be connected to

the three terminals on the master power switch

marked L1, L2, and L3, and the incoming ground

wire must be connected the ground terminal

shown in Figure 16. All wires must have

adequate slack and be clear of sharp objects.

Electrocution or death will occur if this

procedure is attempted with live power supply

wires. All wiring going to the machine must be

disconnected from the power source, and the

power supply shut OFF and locked out before

performing this procedure.

When the wiring job is complete, close and lock

the main electrical box door, otherwise the

machine control panel will be disabled.

Figure 16. Machine power connection locations.

Master

Power

Switch

Pre-drilled Hole

for Incoming

Power

L1

L2

L3

Ground