Mounting chuck or faceplate – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 38

-36-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

O P E R A T I O N

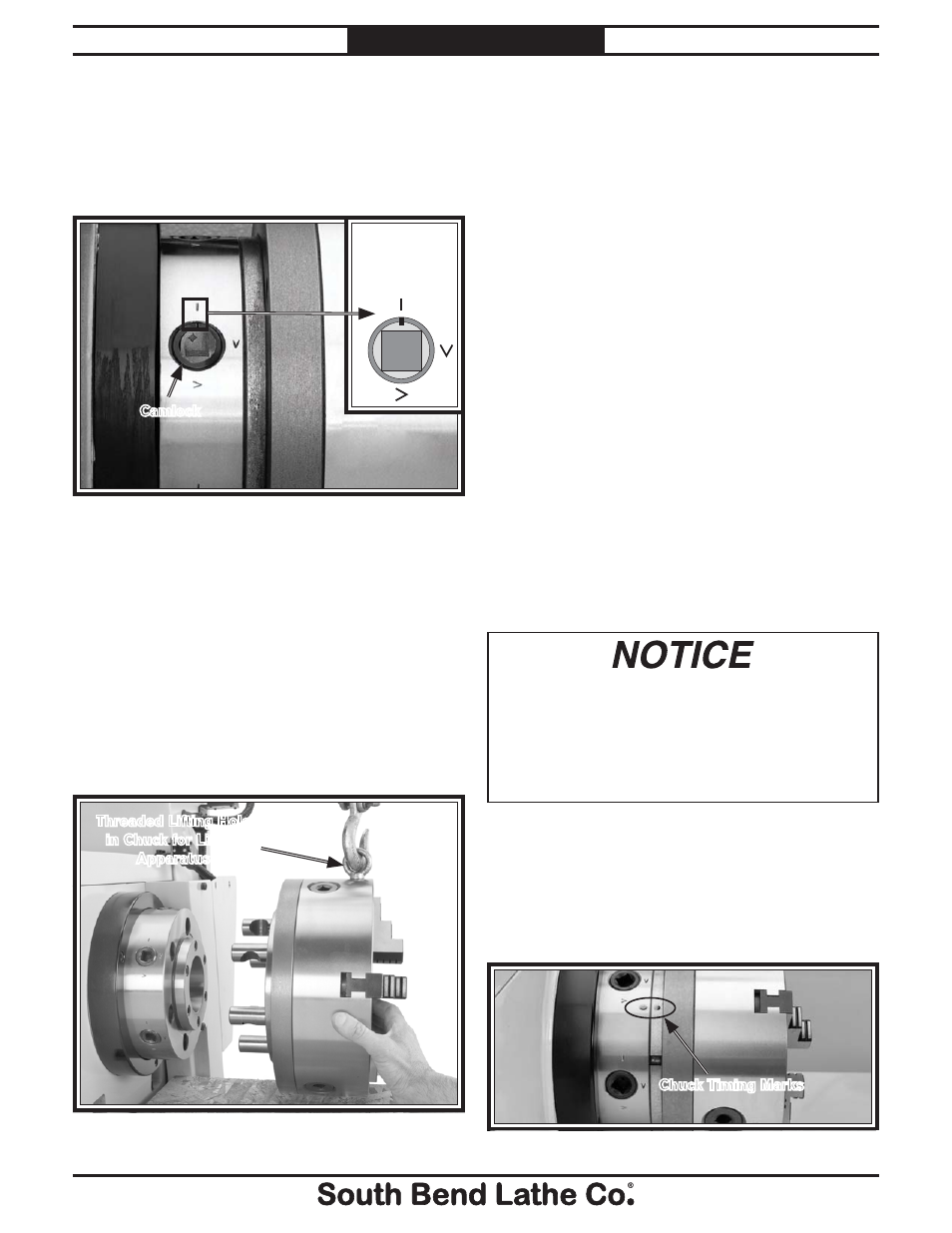

3.

One at a time, use the chuck key to turn

each of the camlocks counterclockwise until

the cam line aligns with the cam release

datum line, as shown in Figure 47. As you

turn the camlocks, they will rise up slightly

from the spindle body.

Figure 47. Camlock loosened with the cam line aligned

with the datum line.

4.

Remove the chuck key, then use a dead-

blow hammer or a wood block to lightly tap

around the circumference of the chuck or

faceplate to break it free from the spindle

taper and camlock sockets. Be sure to

support the bottom of the chuck.

5.

With a rocking motion, carefully remove the

chuck or faceplate from the spindle nose, as

shown in Figure 48, making sure to support

the weight with an adequate chuck cradle.

Figure 48. Removing the 3-jaw chuck from a spindle

nose.

Threaded Lifting Hole

in Chuck for Lifting

Apparatus

Camlock

Cam Release

Datum Line

and Cam Line

Mounting Chuck or Faceplate

The 4-jaw chuck is shipped with six camlock

studs that may have to be installed before

chuck mounting. If you have not yet installed

the camlock studs, complete the instructions in

"Installing and Adjusting Camlock Studs" on

Page 37.

To mount a chuck or faceplate:

1.

DISCONNECT LATHE FROM POWER!

2.

Lay a chuck cradle (see Figure 46) or

plywood under the chuck or faceplate and

over the bedway to protect the precision

ground surfaces from damage and reduce

injury if fingers get pinched.

3.

Clean away debris and oily substances from

the mating surfaces of the spindle and chuck

or faceplate.

4.

Inspect and make sure that all camlock

studs are undamaged, are clean and lightly

oiled, and that the camlock stud cap screws

are in place and snug.

Never install a chuck or faceplate without

having the camlock cap screws in place or

fully tightened. If you ignore this notice,

the chuck may not be removable since the

camlock studs may turn with the camlocks

and never release.

5.

Position the chuck/faceplate in front of the

spindle nose, align the chuck timing marks,

as shown in Figure 49, and align the cam-

lock studs with the sockets, then carefully

insert the chuck or faceplate onto the

spindle.

Figure 49. Chuck timing marks aligned.

Chuck Timing Marks