Aligning – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 46

-44-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

O P E R A T I O N

Aligning

The offset of your lathe was aligned with

the spindle centerline at the factory. We

recommend that you take the time to ensure

that the tailstock is aligned to your own desired

tolerances, especially if you have changed the

offset to cut shallow tapers.

To align the tailstock offset to the spindle

centerline:

1.

Use a precision level to make sure the

bedway is level from side-to-side and from

front-to-back.

— If the bedway is not level, correct this

condition before continuing with this

procedure.

2.

Obtain two pieces of steel round stock 2" in

diameter and 6" long.

3.

Center drill both ends of one piece of round

stock, then set it aside for use in Step 6.

4.

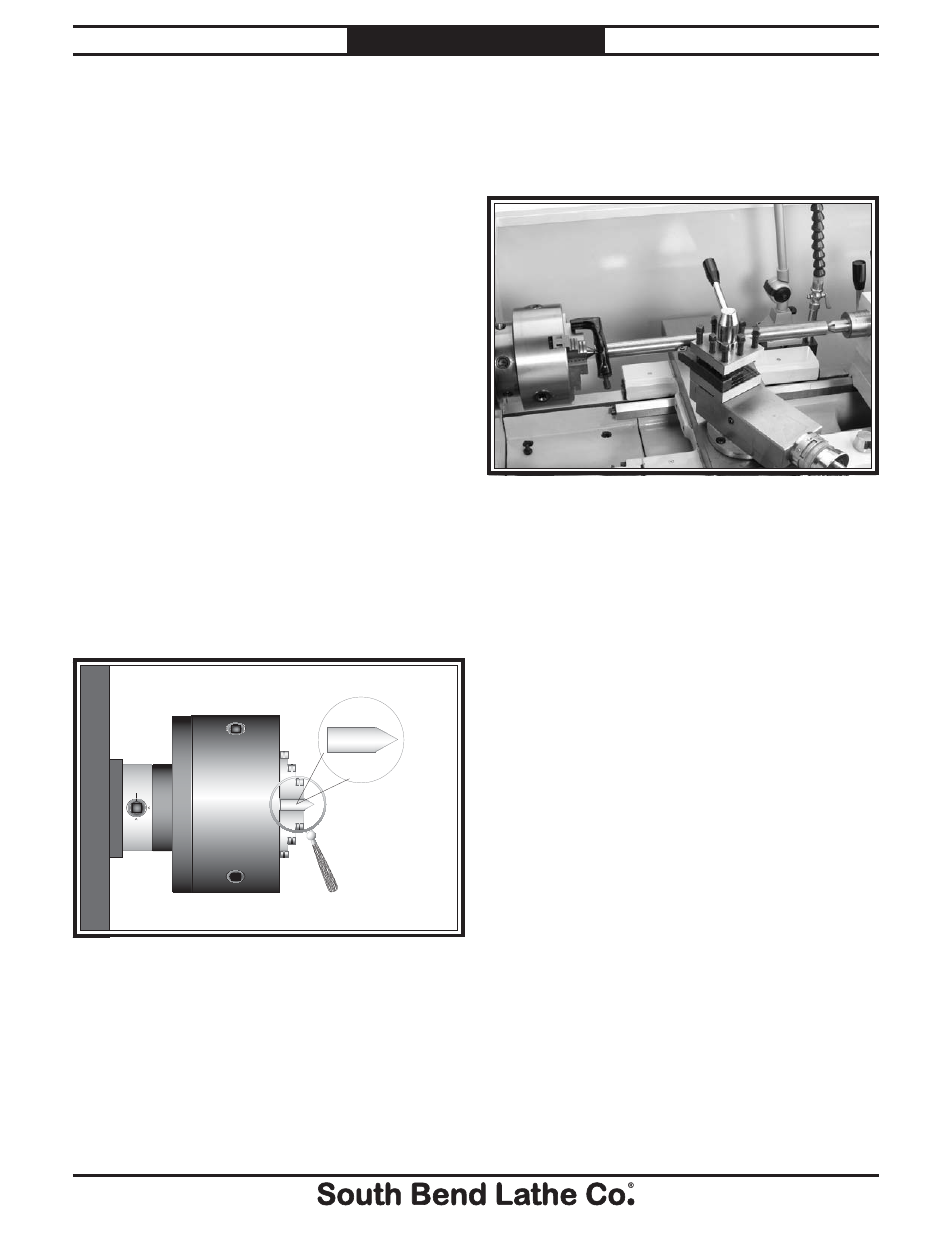

Use the other piece of round stock to make

a dead center, and turn it to a 60° point, as

shown in Figure 68.

Figure 68. Non tapered dead center in the chuck.

5.

Install a center in the tailstock.

6.

Attach a lathe dog to the piece of stock from

Step 3, then mount it between the centers,

as shown in Figure 69.

Figure 69. Example of round stock mounted between

the centers.

7.

Turn 0.010" off the diameter of the stock.

8.

Mount a test or dial indicator so that the

plunger is on the tailstock quill.

Note:

If necessary in the following step, refer to

"To Set Up the Tailstock to Cut a Shallow

Taper" on Page 42 for adjusting the

tailstock offset.

Note:

As long as this dead center remains in the

chuck, the point of the center will remain

true to the spindle centerline. The point will

have to be refinished whenever the center is

removed and then returned to the chuck.