Spindle break-in – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 30

-28-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

P R E P A R A T I O N

23.

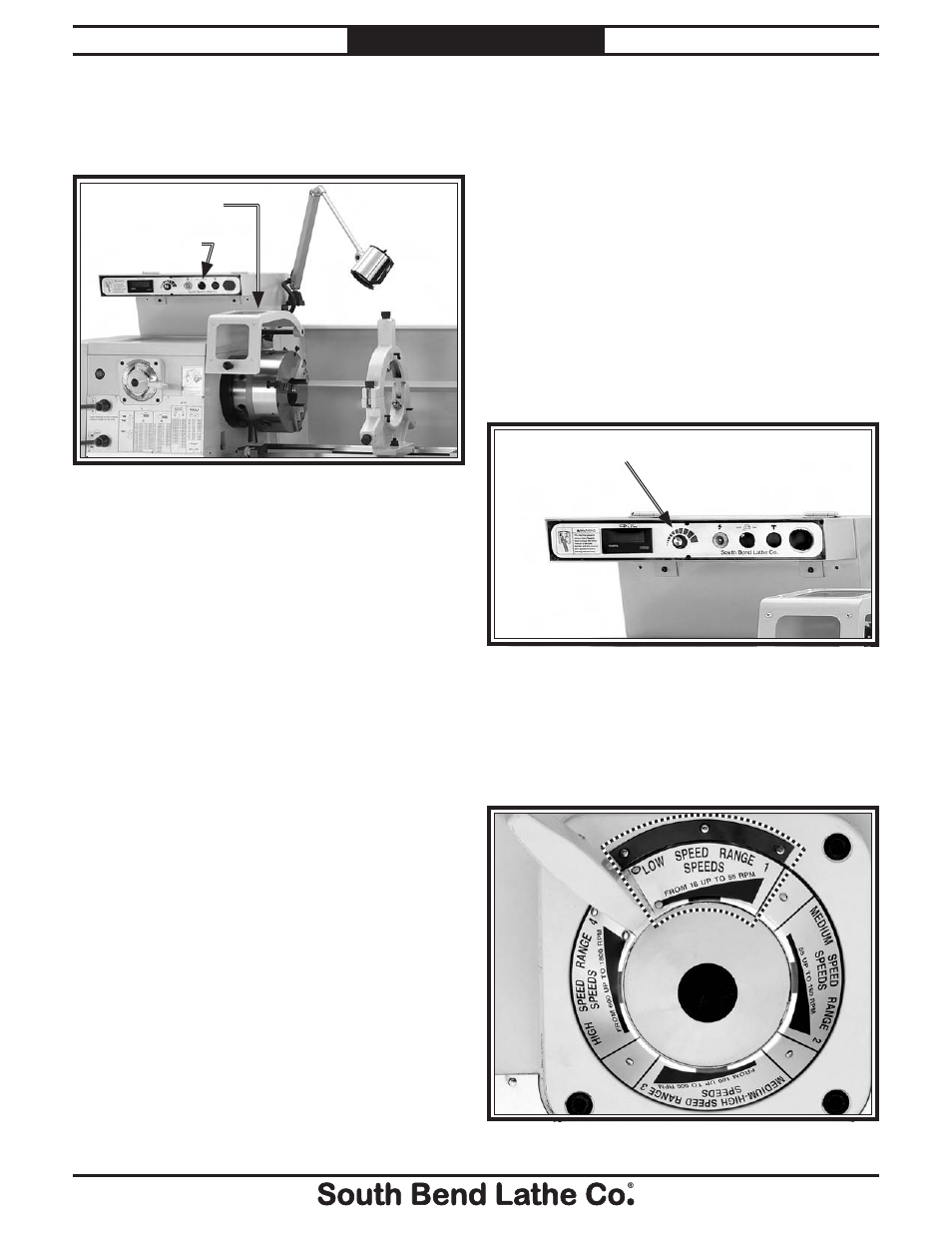

Lift the chuck guard shown in Figure 28,

and try to start the lathe again. The cover

kill switch should prevent the lathe from

starting while the guard is open.

Figure 28. Chuck safety cover.

24.

Close the chuck guard.

25.

Open the cutting fluid valve, and using the

pump switch shown in Figure 28, turn the

cutting fluid pump ON. Verify that fluid

flows from the nozzle, then turn the cutting

fluid pump OFF.

— If no fluid is pumped, but fluid level is

full, no hose kinks exist, and the cutting

fluid nozzle is open, the pump may be

wired with incorrect phase polarity.

Correct the pump phase polarity wiring as

outlined on Page 16.

The test run is now finished. Shut the lathe down

and begin the Spindle Break-In procedure.

Cutting Fluid

Pump Switch

Chuck Guard

Spindle Break-In

It is essential to closely follow the proper break-in

procedures to ensure trouble-free performance.

Complete this process once you have familiarized

yourself with all instructions in this manual and

completed the test run.

To complete the spindle break-in:

1.

Make sure you have completed the Test

Run procedure beginning on Page 25.

2.

Turn the spindle speed dial (Figure 29) all

the way counterclockwise to the minimum

speed.

Figure 29. Spindle speed dial.

Spindle Speed Dial

3.

Move the spindle range lever (Figure 30) to

low speed range 1 (18-55 RPM).

Note:

You may need to slightly rotate the chuck

by hand to engage the lever.

Figure 30. Spindle range lever in low 1.