Installing and adjusting camlock studs – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 39

For Machines Mfg. Since 7/09

Model SB1016/SB1036

-37-

O P E R A T I O N

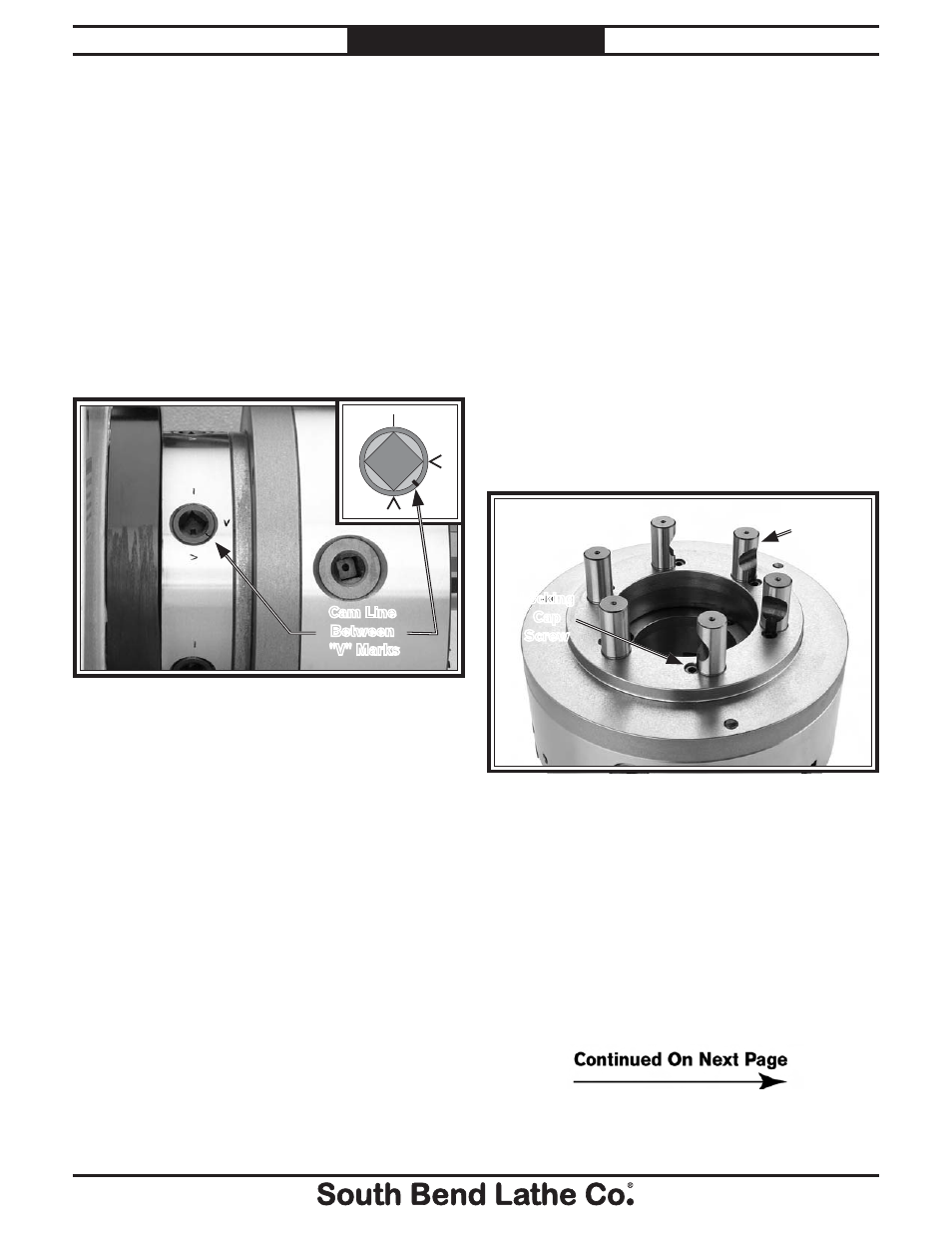

6.

Tighten camlocks in a star pattern to draw

the chuck up evenly on all sides while

reducing chance of misalignment, and make

sure to tighten camlocks in an incremental

manner to ensure that no camlock gets fully

tightened all at once (i.e., snug the camlocks

on the first pass, then moderately tighten on

the next pass, then fully tighten on the third

pass).

As you tighten the camlocks, the chuck or

faceplate will snug up onto the spindle nose.

When fully tightened, the cam line will fall

between the two "V" marks on the spindle

nose, as shown in Figure 50.

Figure 50. Camlock fully tightened with the line

between the "V" marks.

Cam Line

Between

"V" Marks

Note:

If any of the cam lines do not fall between

the "V" marks when the camlock is tight,

you must adjust the offending camlock stud

as discussed in Installing and Adjusting

Camlock Studs on Page on this page.

To make sure that the chuck centerline is

aligned with the spindle centerline, clamp a

test rod in the chuck and use a test indicator

mounted on the bedways to check for

workpiece runout.

Installing and Adjusting Camlock

Studs

Figure 51. Identifying chuck camlock studs and

locking cap screws.

Locking

Cap

Screw

Cam-Lock

Stud

When fitting a chuck or faceplate with camlock

studs, or when mounting a new chuck or

faceplate, it may be necessary to install or adjust

the camlock studs.

Tool Needed

Qty

Hex Wrench 6mm ................................................. 1

To install or adjust camlock studs onto a

chuck or faceplate:

1.

Lay the chuck or faceplate upside down on a

protective, flat surface.

2.

If installed, remove the locking cap screw

adjacent to each of the six cam-lock

mounting holes (see Figure 51).

3.

Thread each cam-lock stud into the chuck

or faceplate until the depth mark shown in

Figure 52 is even with the surface of the

chuck or faceplate and the curved indent

on the side of the stud faces the locking cap

screw hole, as shown in Figure 53. This is

an initial adjustment.