Lifting & moving – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 23

For Machines Mfg. Since 7/09

Model SB1016/SB1036

-21-

P R E P A R A T I O N

Lifting & Moving

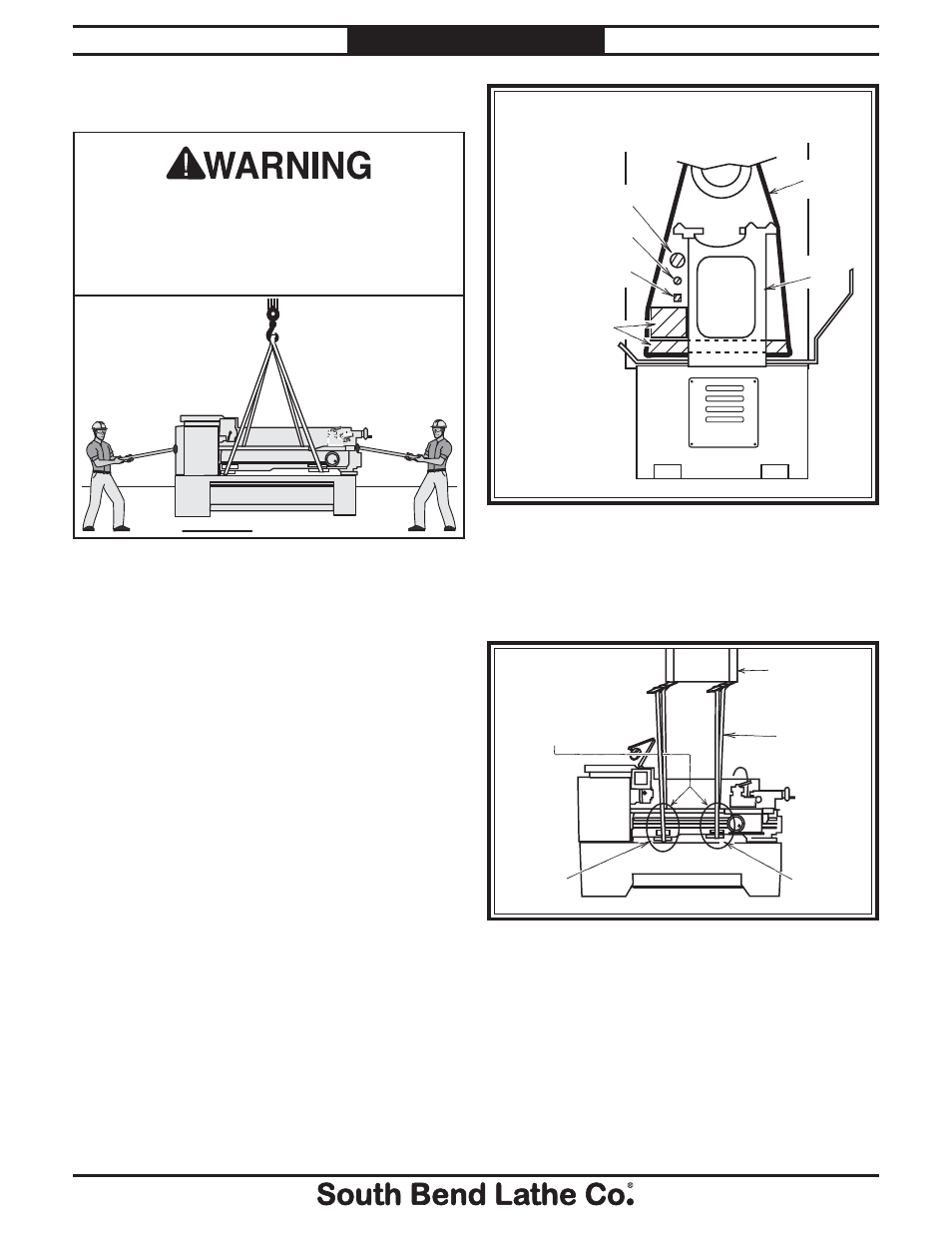

Do not attempt to lift or move this lathe if you do

not have the proper equipment or the necessary

assistance from other people. All lifting

equipment must be rated for at least 10,000 lbs.

to account for dynamic loads from bouncing or

pulling that may be applied while lifting. Refer to

the Things You'll Need section on Page 14 for

details.

To lift and move your lathe:

1.

Prepare the permanent location for the lathe,

and remove the top and sides of the shipping

crate, then remove the small components

from the shipping pallet.

2.

To balance the lifting load, slide the tailstock

and the carriage to the far right end of the

lathe away from the headstock.

3.

Position hardwood blocking under each end

of the bed as shown in Figure 9 to keep the

lifting straps away from the leadscrew, feed

rod, and control rod to prevent bending the

rods.

This machine and its parts are heavy! Serious

personal injury may occur if safe moving

methods are not used. To reduce the risk of a

lifting or dropping injury, ask others for help,

and use power equipment and guide rods.

Lifting

Strap

Lathe

Bed

Leadscrew

Feed Rod

Control

Rod

To Forklift or Lifting Hook

(Loooking at Lifting Setup from Tailstock End)

Hardwood Blocks

and Planks

Positioned as

Required to

Prevent Lifting

Straps from

Bending

Leadscrew

Figure 9. Lifting setup to keep straps from bending

leadscrew or rods.

4.

Attach the lifting straps to a forklift or an

overhead crane, as shown in Figure 10, and

unbolt the lathe from the pallet.

Forklift or

Overhead

Hoist Fixture

Lifting

Straps

Use Blocks as Necessary

to Space Straps Away

from Control Rod,

Feed Rod, and Leadscrew

to Prevent Bending when

the Lathe is Lifted

Hardwood

Blocking

Hardwood

Blocking

Figure 10. Lathe set up for typical lifting.

5.

At each end of the lathe, have an assistant

connect a guide rod to safely keep the lathe

from swaying during lifting and transport.

6.

Raise the lathe a couple of inches and place

the lathe. If lathe balance is questionable

however, or any other problem is suspected,

lower the lathe and correct the problem.