Southbend 16" x 60" Lathe 440V w/ Dro sb1015f User Manual

New & changed parts, Manual insert, Ref part # description

Manual Insert

PHONE: (360) 734-1540 •

www.southbendlathe.com

MODEL SB1015F

16" X 60" LATHE 440V w/DRO

Copyright © June, 2011 by South Bend Lathe Co.

WARNING: No portion of this manual may be reproduced without written approval.

#BL14236 Printed in USA

The Model SB1015F Lathe is the same machine as the Model SB1015 except for the following:

• Added a 2-Axis Fagor Digital Readout (DRO).

Except for the differences noted in this insert, all other content in the Model SB1015 Owner’s Manual

applies to this machine. Before operating your new lathe, you MUST read and understand this insert,

the entire Model SB1015 Owner’s Manual, and the Fagor DRO Owner’s Manual to reduce the risk of

injury when using this machine. Keep this insert for later reference.

If you have any further questions about this manual insert or the differences between the Model

SB1015F and the Model SB1015, contact our Technical Support at (360) 734-1639 or email

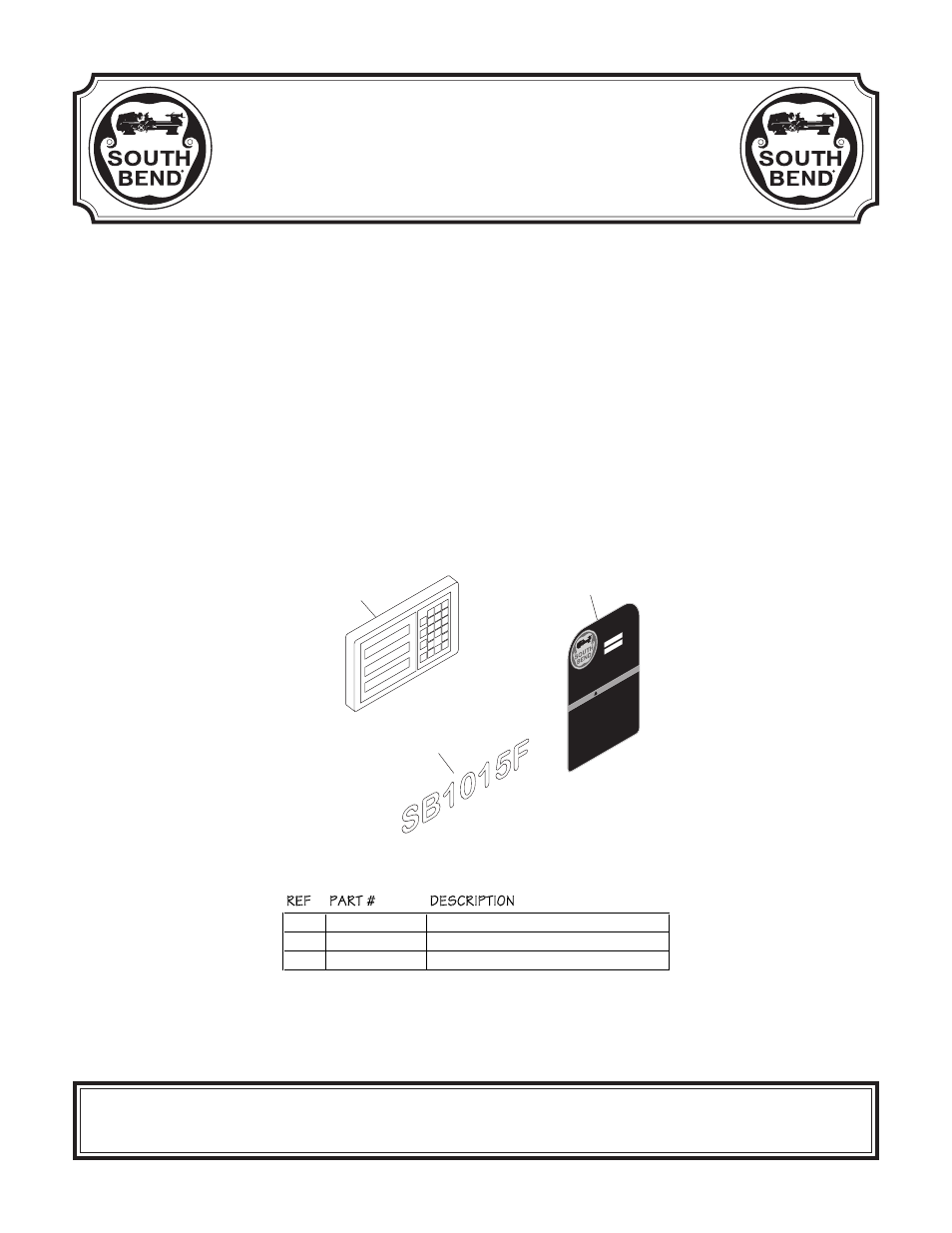

REF PART #

DESCRIPTION

2318 PSB1014F2318

DRO ASSEMBLY FAGOR 20i-T 2-AXIS

2407 PSB1015F2407 MACHINE ID LABEL

2416 PSB1015F2416

MODEL NUMBER LABEL

New & Changed Parts

2318

2416

2407

Made in T

aiwan to South Bend Specifica

tions

MODEL SB1015F

16" x 60" EVS

TOOLR

OOM

LATHE

w/DR

O

MFG Date

Serial N

umber

TO REDUCE THE RISK OF SERIOUS PERSONAL INJUR

Y WHILE USING THIS

MA

CHINE:

1.

Read and understand manual bef

ore star

ting

.

2.

Always wear appro

ved e

ye protec

tion.

3.

Make sur

e the mac

hine is connec

ted to a grounded po

wer sourc

e.

4.

Keep all guards in place.

5.

DO NO

T wear loose c

lothing

, glo

ves

, or je

welr

y; secur

e long hair and

roll up long slee

ves

.

6.

Disc

onnec

t po

wer bef

ore ser

vice, maintenanc

e, or adjustments

.

7.

DO NO

T oper

ate when tir

ed or under the influence of

drugs or alc

ohol.

8.

Make sur

e the mac

hine is proper

ly adjusted/set up bef

ore star

ting

.

9.

Change c

utting fluid r

egular

ly and av

oid c

ontac

t with skin.

10.

Make sur

e w

orkpiec

e is proper

ly and sec

urely held in the chuc

k and has

safe c

lear

ance through full rota

tion bef

ore star

ting the la

the.

11.

Nev

er leav

e the chuc

k ke

y in the c

huck.

12.

Nev

er touch the chuc

k or w

orkpiec

e when it is in motion.

13.

Nev

er leav

e the la

the running una

ttended.

14.

Make sur

e long w

orkpieces ar

e proper

ly suppor

ted.

15.

Always use the proper speed r

ate f

or the ma

terial y

ou ar

e tur

ning

.

16.

Do not allo

w c

hildr

en to hav

e unsuper

vised ac

cess to the mac

hine.

WA

RNI

NG

!

!

Motor

: 7.5HP

, 440V

, 3-Ph, 60H

z

Full Load Amp D

raw: 10.75A

Swing Ov

er Be

d: 16.14"

Distance Between Centers: 60"

Swing Ov

er Cross Slide: 10.375"

Swing Ov

er Gap: 22.95"

Spindle Nose T

o Gap (M

ax.): 10.2"

Cross Slide T

rav

el: 9"

Compound T

rav

el: 5.1"

Spindle Nose: D1-6 Camloc

k

Spindle Bor

e: 2-1/16"

Taper Inside Spindle: MT#6

Taper Inside T

ailstock: MT#4

Weight: 3300 lbs

.