Way tool post, Aligning cutting tool with spindle centerline – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 52

-50-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

O P E R A T I O N

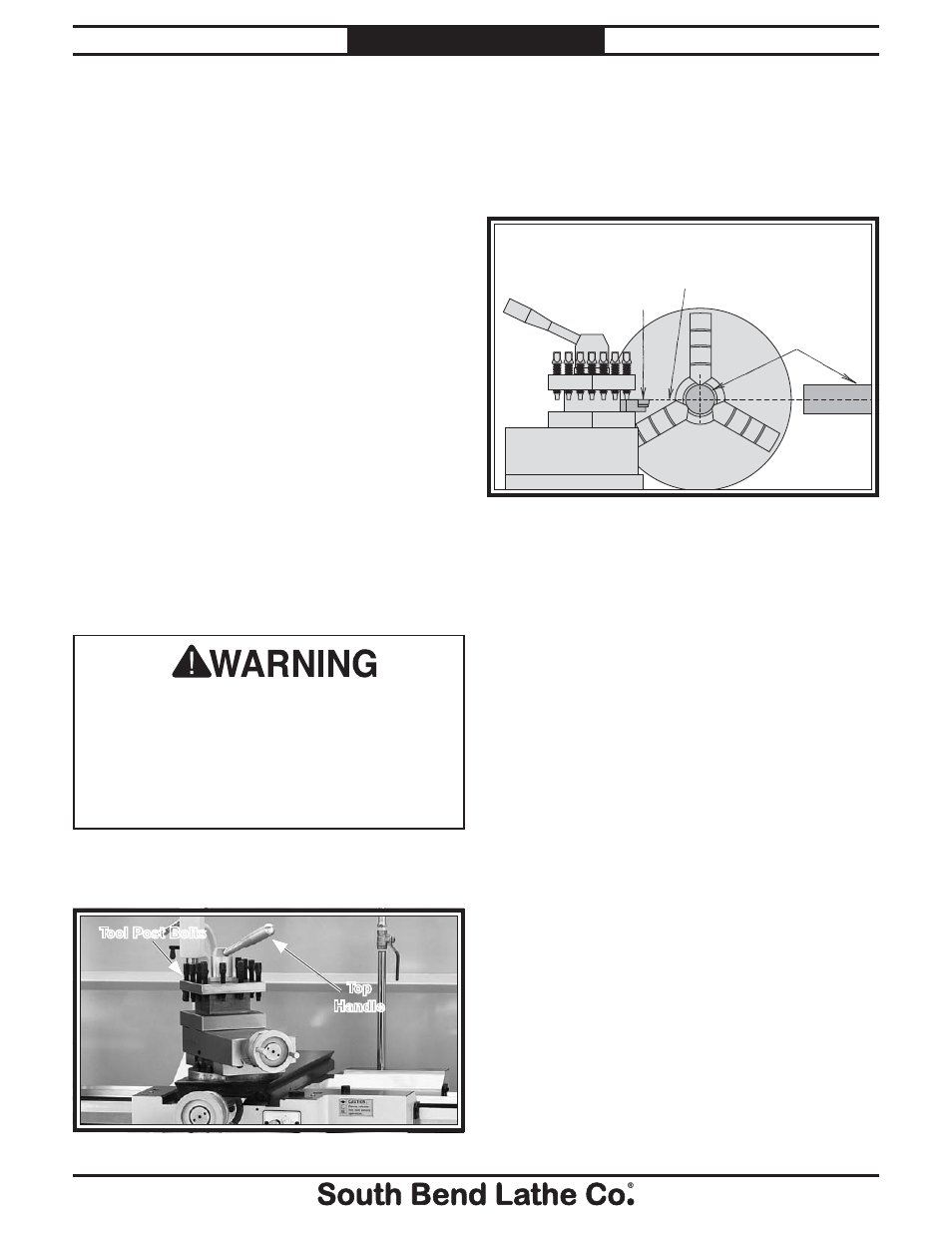

The 4-way tool post is mounted on top of the

compound slide, and allows a maximum of four

tools to be loaded simultaneously. Quick indexing

to different tools is accomplished by loosening the

top handle, rotating the tool post to the desired

position, then re-tightening the handle to lock

the tool into position.

Tool Needed

Qty

Tool Post T-Wrench ............................................... 1

To load the tool post:

1.

Choose the desired cutting tool.

2.

Loosen the tool post bolts so that the cutting

tool can fit underneath them.

Note:

If necessary, place one steel shim of the

required thickness underneath the cutting

tool, so the cutting tip is properly aligned

with the workpiece. The shim should be

as long and as wide as the cutting tool

to properly support it, a set of standard

automotive feeler gauges work well for this.

4-Way Tool Post

3.

Firmly secure the cutting tool with at least

two tool post bolts shown in Figure 79.

Figure 79. 4-Way tool post.

Top

Handle

Tool Post Bolts

Over-extending a cutting tool from the tool

post will increase the risk of it breaking during

operation, which may cause metal pieces to

be thrown at the operator or bystanders with

great force. Only extend a cutting tool 2.5

times the width of its cross-section or less

(i.e., 2.5 x 0.5" = 1.25").

Aligning Cutting Tool with Spindle

Centerline

For most operations, the cutting tool tip should

be aligned with the spindle centerline, as

illustrated in Figure 80.

Figure 80. Cutting tool aligned with workpiece center

(view from tailstock).

Cutting

Tool

Workpiece

Workpiece

Center

Line

There are a number of ways to check and align

the cutting tool to the spindle centerline. Below

are two common methods:

Align the tip of the cutting tool with a center

s

installed in the tailstock (refer to instructions

that follow). For this to work, the tailstock

must be aligned to the spindle centerline

(refer to Aligning Tailstock on Page 44).

Make a facing cut on a piece of round bar

s

stock. If the tool is above/below the spindle

centerline, a nub will be left in the center

of the workpiece. Adjust the height of the

workpiece, then repeat the facing cut to check

the adjustment. Repeat as necessary until the

center of the workpiece is smoothly faced.