Description of controls & components, Main power control, Headstock controls – Southbend 18' & 60: EVS Toolroom Lathes 220v sb1016 User Manual

Page 34: Control panel

-32-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

O P E R A T I O N

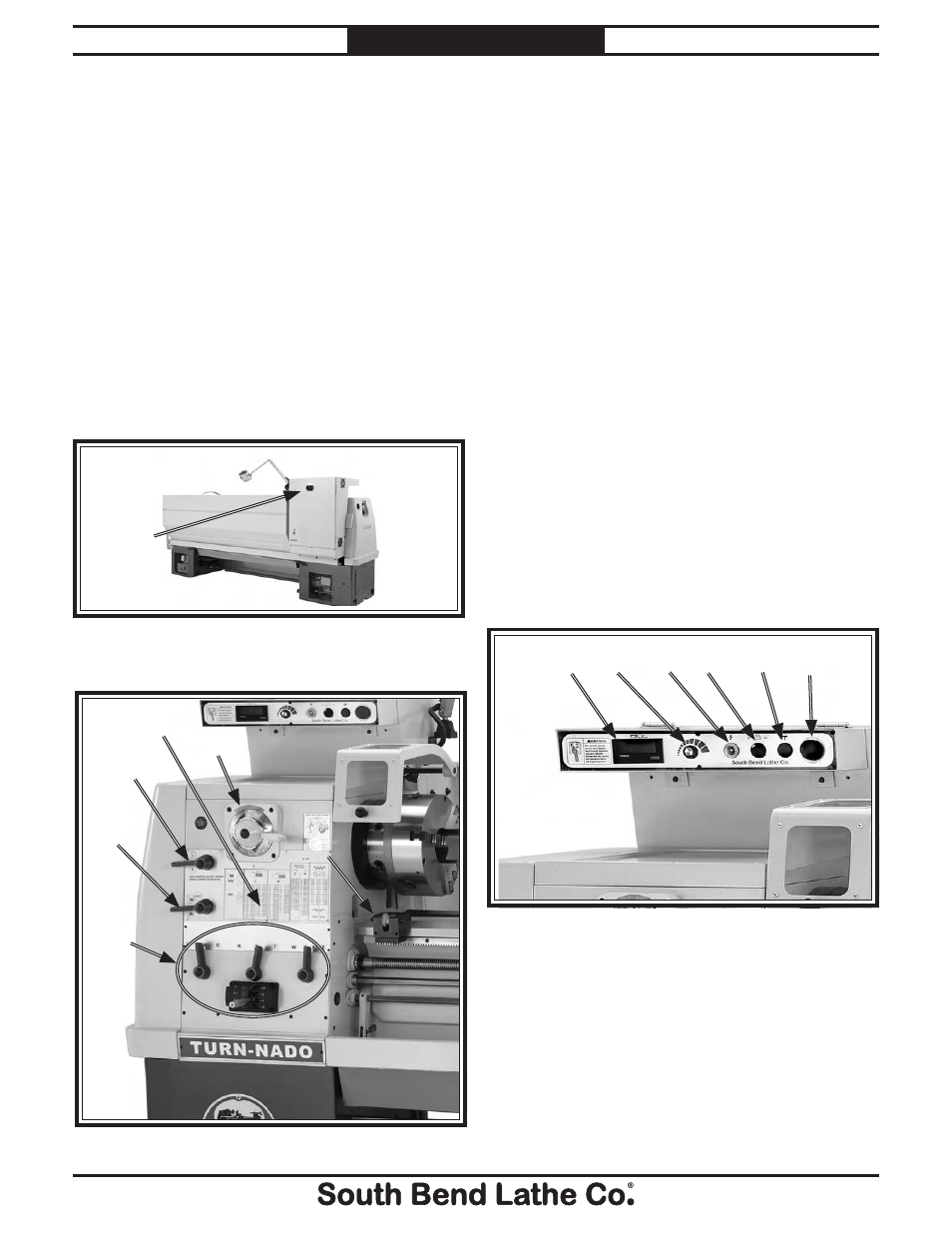

Refer to the following figures and descriptions to

learn about the basic controls of this machine.

Main Power Control

A. Master Power Switch:

The rotary switch

shown in Figure 37 toggles incoming power

ON/OFF to the lathe. It also prevents the

electrical box door from being opened when

the switch is ON. If switched to OFF, this

switch is not a safe alternative to completely

disconnecting the machine from power when

wiring, servicing, or making repairs.

B. Quick Change Gearbox Levers:

Controls the

leadscrew and feedrod speed for threading

and feed operations.

C. Headstock Feed Direction Lever:

Controls

the direction that the leadscrew and feed rod

rotate.

D. Gearbox Range Lever:

Shifts the quick

change gearbox from neutral into high or

low.

E. Threading and Feed Chart:

Shows the

configurations of the gearbox levers and

displays the positions of the various gears for

different threading or turning options.

F.

Spindle Speed Range Lever:

Controls the

speed ranges available to the spindle.

G. Micrometer

Stop:

Clamps along the way, and

serves as a stopping point indicator, so when

cutting shoulders the tool tip can be stopped

at exactly the same point every time.

Headstock Controls

B

Figure 38. Headstock controls.

Description of Controls

& Components

C

D

E

F

G

Control Panel

Figure 39. Control panel.

M

L

K

J

I

H

H. Tachometer Display:

Displays the current

spindle speed in RPM.

I. Spindle Speed Dial:

When rotated, the EVS

dial electronically varies the spindle speed

within each of the four available spindle

speed ranges.

J. Power Light:

Illuminates when lathe is

receiving power and the controls are LIVE.

A

Figure 37. Master power switch.