Milwaukee LSM40MP-2 User Manual

Page 14

14

NOTE:.DIAGRAMS.&.ILLUSTRATIONS.ARE.NOT.TO.SCALE.

Figure 18

Vertical (Offset) Installation

Analyze. the. vent. routing. and. determine. the.

quantities.of.vent.sections.and.number.of.elbows.

required..Refer.to.Vertical Vent Figures and

Tables on Page 16..to.select.the.type.of.vertical.

installation.desired..Vent.sections.are.available.

in.net.lengths.of.4-1/2".(114.mm),.10-1/2".(267.

mm),.22-1/2".(572.mm),.34-1/2".(876.mm).and.

46-1/2".(1181.mm)..Refer.to.the.Vent Section

Length Chart on Page 13.for.an.aid.in.select-

ing.length.combinations..Elbows.are.available.

in.90°.and.45°.configurations..Refer.to.Figure

21 on Page 15 .for.the.SV8.E45.and.SV8.E90.

elbow.dimensional.specifications....

Where. required,. a.

telescopic vent section

(SV8LA)..may.be.used.to.provide.the.installer.

with.an.option.in.installing.in.tight.and..con-

fined.spaces.or.where.the.vent.run.made.up.

of. fixed. length. pieces. develops. a. joint. in. a.

undesirable.location,.or.will.not.build.up.to.the.

required. length.. The. SV8LA. Telescopic. Vent.

Section.has.an.effective.length.of.from.1-1/2".

(38.mm).to.6-3/4".(171.mm)..The.SV8LA..is.

fitted.with.a.dimpled.end.(identical.to.a.normal.

vent.section.component).and.a.plain.end.with.

3. pilot. holes.. Slip. the. dimpled. end. over. the.

locking.channel.end.of..a.standard..SV8.vent.

component.the.required.distance.and.secure.

with.three.screws.

Maintain a minimum 1" (25 mm) clearance

to combustible materials for all vertical ele-

ments. Clearances for all horizontal elements

are 3" (76 mm) on top, 1" (25 mm) on sides

and 1" (25 mm) on the bottom.

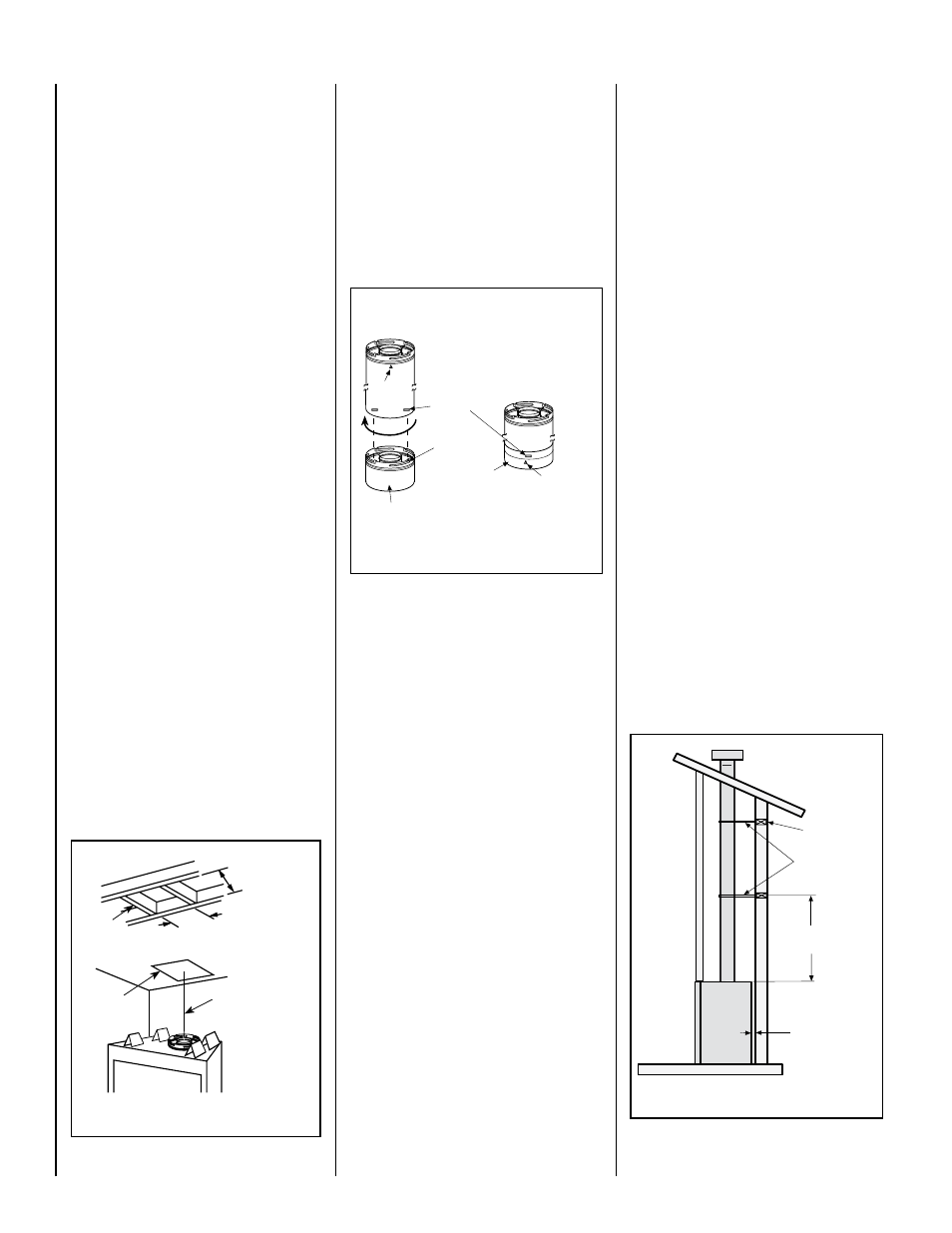

A..Frame ceiling opening -.Use.a.plumb.line.

from.the.ceiling.above.the.appliance.to.locate.

center. of. the. vertical. run.. Cut. and/or. frame.

an.opening,.13".x.13"..(330.mm.x.330.mm).

inside. dimensions,. about. this. center. mark.

(Figure 18).

Figure 19

Align the dimple (four places) of the

upper vent section with the opening

of the locking incline channel on

the lower vent section or appliance

collar. Twist vent component clock-

wise to engage and seal until arrow

and dimple align.

Dimple

Locking Incline

Channel

Connected Vent

Sections

Arrow

Arrow

Appliance Collar or

Vent Section

Figure 20

Blocking

Support Straps

(Plumber's tape)

8 feet (2.4 m)

Maximum

1 inch (25.4

mm) minimum

clearance to

combustibles

Roof

Framing

Ceiling

Framing

Plumb

Bob

13” Min.

(330 mm)

13” Min.

(330 mm)

Push.the.vent.component.against.the.previous.

section. until. it. fully. engages,. then. twist. the.

component.clockwise.running.the.dimples.down.

and.along.the.incline.channels.until.they.seat.at.

the.end.of.the.channels..This seating position

is indicated by the alignment of the arrow and

dimple as shown in.Figure 19.

D.. Install firestop/spacer at ceiling -.When.

using.Secure.Vent,.use.SV8BF.firestop/spacer.

at.ceiling.joists..If.there.is.living.space.above.

the.ceiling.level,.the.firestop/spacer.must.be.

installed.on.the.bottom.side.of.the.ceiling..If.attic.

space.is.above.the.ceiling,.the.firestop/spacer.

must.be.installed.on.the.top.side.of.the.joist..

Route. the. vent. sections. through. the. framed.

opening. and. secure. the. firestop/spacer. with.

8d.nails.or.other.appropriate.fasteners.at.each.

corner.. Remember to maintain 1" (25 mm)

clearance to combustibles, framing members,

and attic or ceiling insulation when running

vertical chimney sections. Attic insulation

shield (H3908) may be used to obtain the

required clearances indicated here. See

installation accessories on Page 30. .The.gap.

between.the.vent.pipe.and.a.vertical.firestop.can.

be.sealed.with.non-combustible.caulking.

E..Support the vertical vent run sections -

Note - Proper venting support is very important.

The weight of the vent must not be supported

by the fireplace in any degree..

Support. the. vertical. portion. of. the. venting.

system.every.8.feet.(2.4.m).above.the.fireplace.

vent.outlet..

B.. Attach vent components to appliance

-.Secure Vent.SV8.direct-vent.system.compo-

nents.are.unitized.concentric.pipe.components.

featuring.positive.twist.lock.connections.(see

Figure 19)...

All.of.the.appliances.covered.in.this.document.

are.fitted.with.collars.having.locking.inclined.

channels..The.dimpled.end..of.the.vent.com-

ponents.fit.over.the.appliance.collar.to.create.

the.positive.twist.lock.connection.

To.attach.a.vent.component.to.the.appliance.

collar,.align.the.dimpled.end.over.the.collar,.

adjusting. the. radial. alignment. until. the. four.

locking. dimples. are. aligned. with. the. inlet. of.

the.four.inclined.channels.on.the.collar.(refer to

Figure 19)...Push.the.vent.component.against.

the.collar.until.it.fully.engages,.then.twist.the.

component. clockwise,. running. the. dimples.

down.and.along.the.incline.channels.until.they.

seat.at.the.end.of.the.channels...The.unitized.

design.of.the.Secure Vent™.components.will.

engage.and.seal.both.the.inner.and.outer.pipe..

without.the.need.for.sealant.or.screws...If.desired.

a.#6.x.1/2".screw.may.be.used.at.the.joint,.but.

it.is.not.required.as.the.pipe.will.securely.lock.

when.twisted.

C. Attach vent components to each other

-. Other. vent. sections. may. be. added. to. the.

previously.installed.section.in.accordance.with.

the. requirements. of. the. vertical. vent. figures.

and.tables...To.add.another.vent.component.

to.a.length.of.vent.run,.align.the.dimpled.end.

over.the.inclined.channel.end.of.the.previously.

installed.section,.adjusting.the.radial.alignment.

until.the.four.locking.dimples.are.aligned.with.

the.inlets.of.the.four.incline.channels.of.the.

previous.section..