Miller Electric Welder User Manual

Page 98

OM-196 188 Page 92

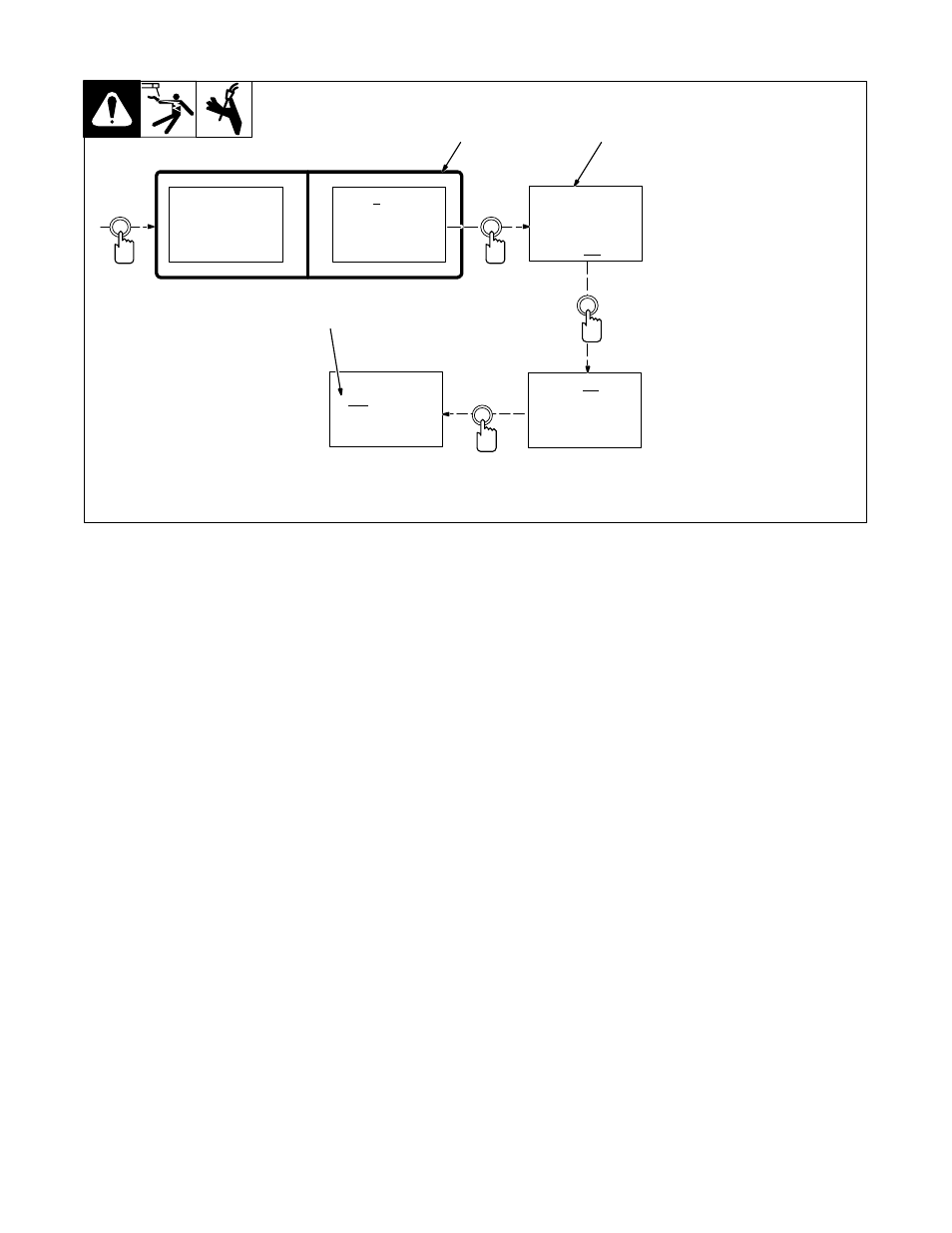

10-3. Selecting Teach Point Wire Feed Speed For Pulse Welding Program

1

Process Display

When unit is first turned On,

Process is the default screen, at

other times use mode select button

to select Process.

2

Teach Display

Use parameter select button to

select Teach.

Use increase/decrease buttons to

select On.

3

IPM (Teach Point)

The parameters associated with

this wire feed speed teach point can

be modified. The wire feed speed

value itself cannot be changed from

the set point.

To set or adjust teach point parame-

ters, go to Section 10-4.

3

1

> Process

Sequence

SharpArc

Card

> Prg 1

Pulse

035” Steel

Argon – Oxy

Pulse

035” Steel

> Teach Off

Teach On

> 400 IPM

28.1 Vpk

340 Apk

> Teach On

400 IPM

28.1 Vpk

340 Apk

2

Mode

Select

Parameter

Select

Parameter

Select

Increase/

Decrease

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)