5. weld output terminals and selecting cable sizes – Miller Electric Welder User Manual

Page 20

OM-196 188 Page 14

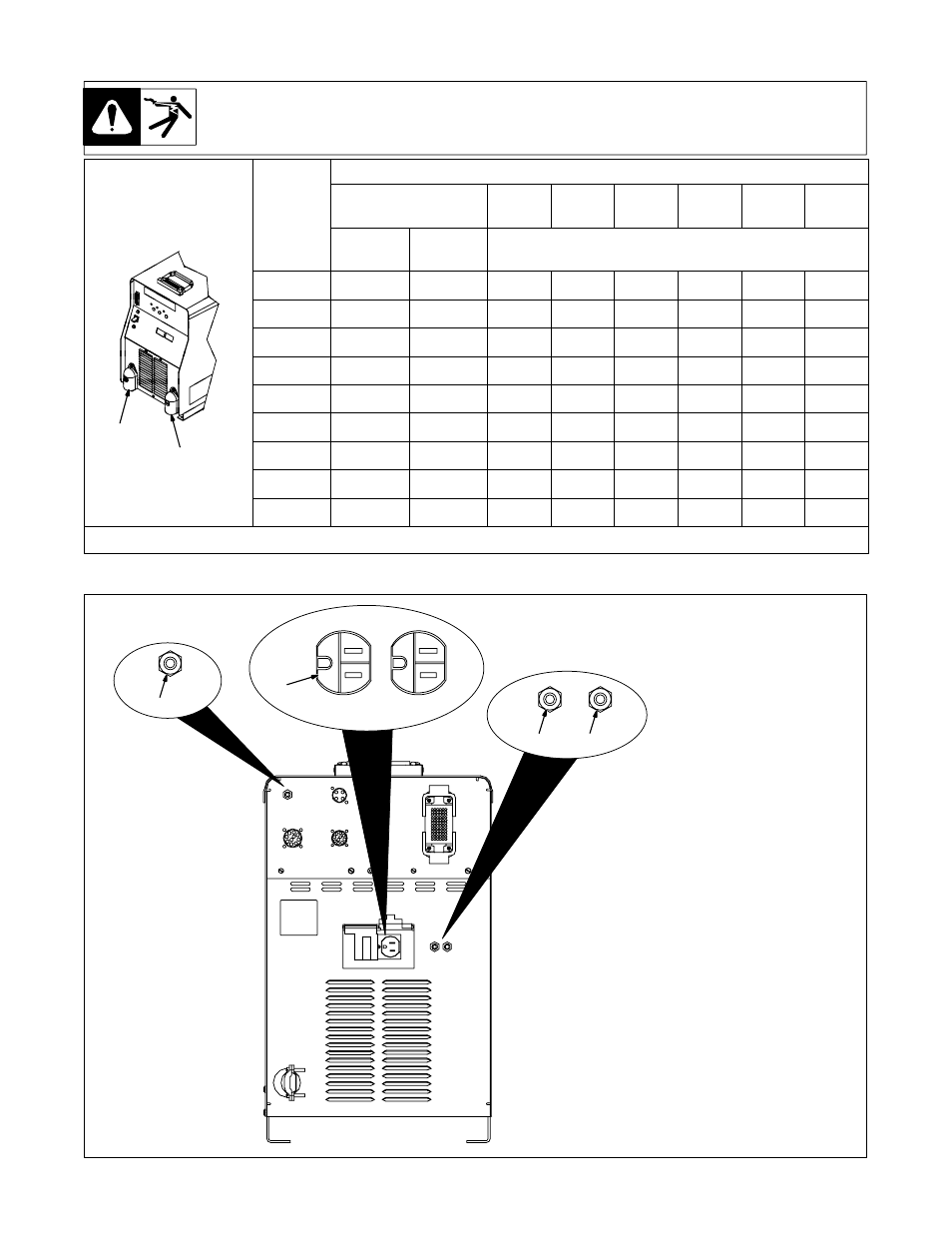

3-5.

Weld Output Terminals And Selecting Cable Sizes

Total Cable (Copper) Length In Weld Circuit Not Exceeding

30 m (100 ft) Or Less

45 m

(150 ft)

60 m

(200 ft)

70 m

(250 ft)

90 m

(300 ft)

105 m

(350 ft)

120 m

(400 ft)

Welding

Amperes

10 – 60%

Duty Cycle

60 – 100%

Duty Cycle

10 – 100% Duty Cycle

100

25

25

25

35

35

50

55

55

150

35

35

35

50

55

70

95

95

200

35

35

50

55

70

95

120

120

250

35

50

55

70

95

120

2-70

2-70

300

50

55

70

95

120

2-70

2-95

2-95

Positive

(+)

350

55

70

95

120

2-70

2-95

2-95

2-120

Positive

(+)

Negative

(–)

400

55

70

95

120

2-70

2-95

2-120

2-120

Ref. 801 914-A

Negative

(–)

500

70

95

120

2-70

2-95

2-120

3-95

3-95

Ref. 801 914-A

600

95

120

2-70

2-95

2-120

3-95

3-120

3-120

*Weld cable size (mm

2

) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere.

S-0007E

802 748

1

115 V 10 A AC Receptacle

Power is shared between duplex

receptacle and internal 14 socket

receptacle.

2

Circuit Breaker CB1

3

Circuit Breaker CB2

CB1 protects duplex receptacle

and 115 volts ac portion of internal

14 socket receptacle from

overload.

Press button to reset breaker.

CB2 protects 24 volts ac portion of

internal 14 socket receptacle from

overload.

Press button to reset breaker.

4

Circuit Breaker CB1

CB1 protects the motor control

circuitry from overload. If CB1 trips,

the wire drive motor is inoperative.

Press button to reset breaker.

2

3

1

3-6.

115 Volts AC Duplex Receptacle And Circuit Breakers

4