9. rear panel connections – Miller Electric Welder User Manual

Page 22

OM-196 188 Page 16

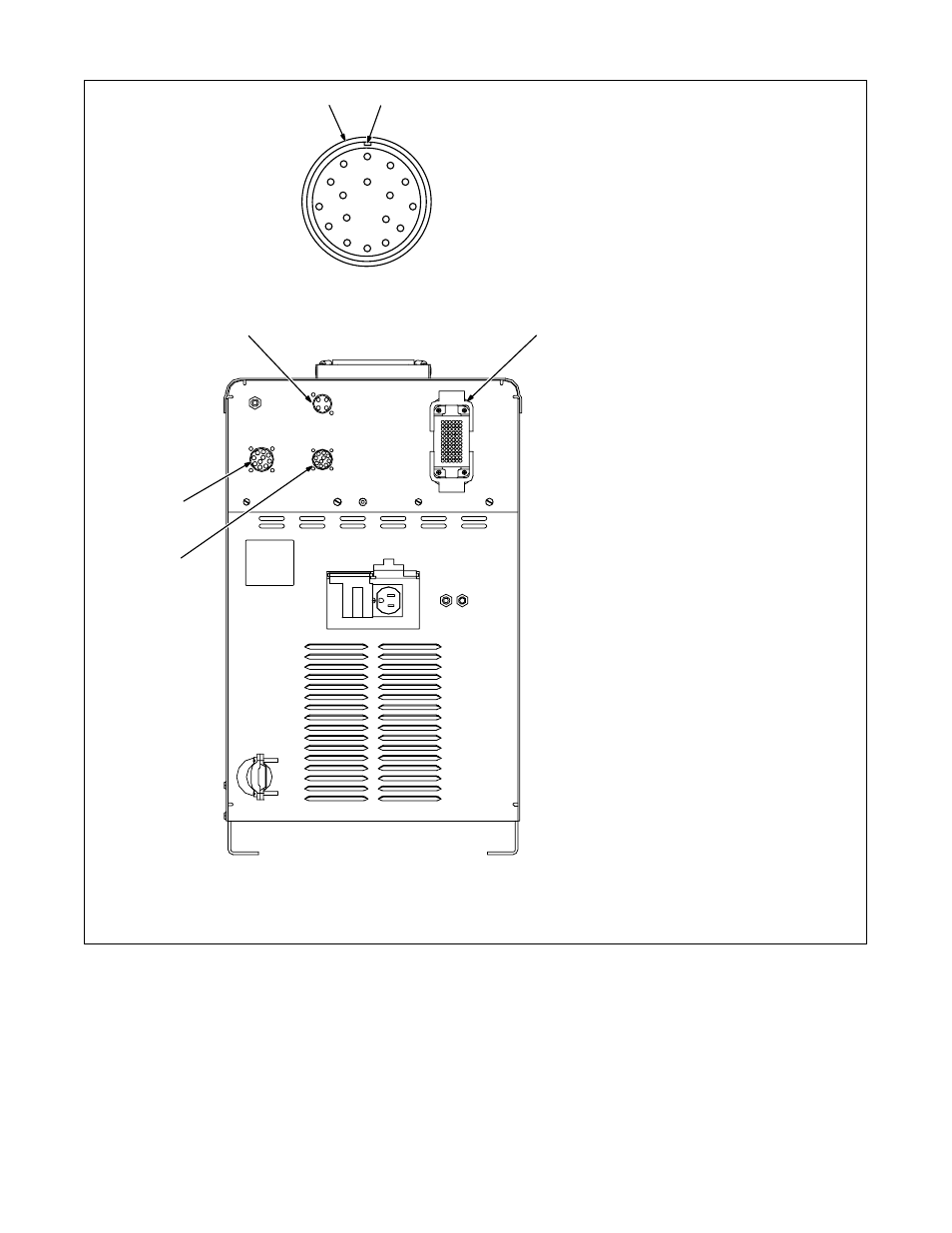

3

5

6

4

1

Receptacle

2

Keyway

3

4-Pin Receptacle (Optional

External Voltage Sensing

Connection)

To connect interconnecting cord to

receptacle, align keyway, insert

plug, and tighten threaded collar.

Secure ring terminal on remaining

end of cord to work.

4

Peripheral Receptacle

Receptacle provides connection to

touch sensor, water flow switch, jog

+/–, and n/o relay contacts circuitry.

5

Robot Control Receptacle

(Remote Program Select

Connection To Robot Control)

To connect matching interconnect-

ing cord to one of the above

receptacles, align keyway, insert

plug, and tighten threaded collar.

Connect remaining end of cord to

matching receptacle on applicable

equipment (see Section 3-4).

6

10-Socket Receptacle (Wire

Feed/Shielding Gas Control

Connection To Motor Drive

Assembly)

Ref. S-0003-A / 802 748

1

B

M

C

N

L

D

R

S

K

E

G

J

F

H

P

T

A

2

Example Receptacle

3-9.

Rear Panel Connections

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)