Motorola SYMBOL MINISCAN MSXX04 User Manual

Page 37

Installation 2 - 13

Acrylic

When fabricated by cell-casting, acrylic has very good optical quality and low initial cost. However, protect the

surface from the environment as acrylic is susceptible to attack by chemicals, mechanical stresses, and UV light.

Acrylic has reasonably good impact resistance and can be ultrasonically welded.

CR-39

CR-39 is a thermal-setting plastic produced by the cell-casting process, and is commonly used in plastic eye

glasses lenses. CR-39 has excellent chemical and environmental resistance, including good surface hardness.

Typically it does not require hard-coating, but can be hard coated for severe environments. CR-39 has reasonably

good impact resistance and cannot be ultrasonically welded.

Chemically Tempered Float Glass

Glass is a hard material which provides excellent scratch and abrasion resistance. However, unannealed glass is

brittle. Increasing flexibility strength with minimal optical distortion requires chemical tempering. Glass cannot be

ultrasonically welded and is difficult to cut into odd shapes.

CAUTION

Consult an opto-mechanical engineer to recommend an appropriate window material and to

determine if coatings are appropriate for the specific application.

NOTE

Do not use polycarbonate material.

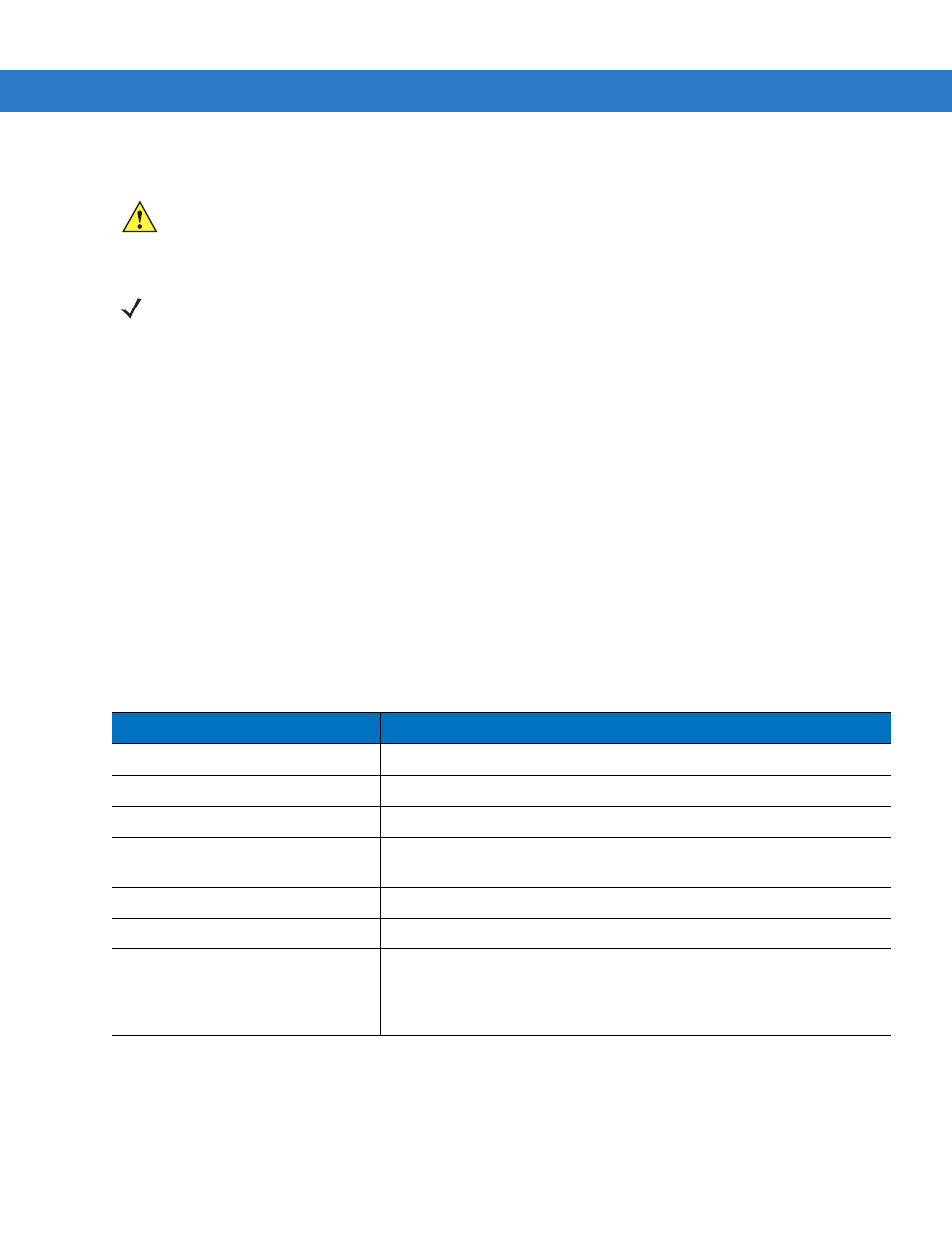

Table 2-3

Suggested Window Properties

Property

Description

Material

Red cell-cast acrylic.

Spectral Transmission

85% minimum from 640 to 690 nanometers.

Thickness

0.059 ± 0.005

Wavefront Distortion (transmission)

0.2 wavelengths peak-to-valley maximum over any 0.08 in. diameter within

the clear aperture.

Clear Aperture

To extend to within 0.04 in. of the edges all around.

Surface Quality

60-20 scratch/dig

Coating

Both sides to be anti-reflection coated to provide 0.5% max reflectivity

(each side) from 640 to 690 nanometers at nominal window tilt angle.

Coatings must comply with the hardness adherence requirements of

MIL-M-13508.