Adjusting the blade guides – Grizzly G0503 User Manual

Page 44

Model G0503 (Mfg. Since 12/08)

-42-

Each blade guide assembly consists of a guide

block and a support wheel.

Each metal guide block has a guide slot that sta-

bilizes the up/down movement of the blade and

a support wheel to control backward movement.

the guide block alignment should be checked

each time a blade is installed.

Adjusting the

Blade Guides

Tools Needed

Qty

wrench/socket 17mm ...................................... 2

t-handle wrench 19mm .................................. 1

wrench/socket 19mm ...................................... 1

To align the guide blocks:

1. rotate the wheels by hand and watch how

the blade feeds through the blade guides.

—if the blade feeds through the blade guide

without touching the guide block or rotat-

ing the support wheel, no adjustment is

necessary.

—if the blade rotates the support wheel but

does not touch the guide blocks, go to

Adjusting the Support Wheel on

page 43.

—if the blade rubs against the guide blocks,

continue to the next step.

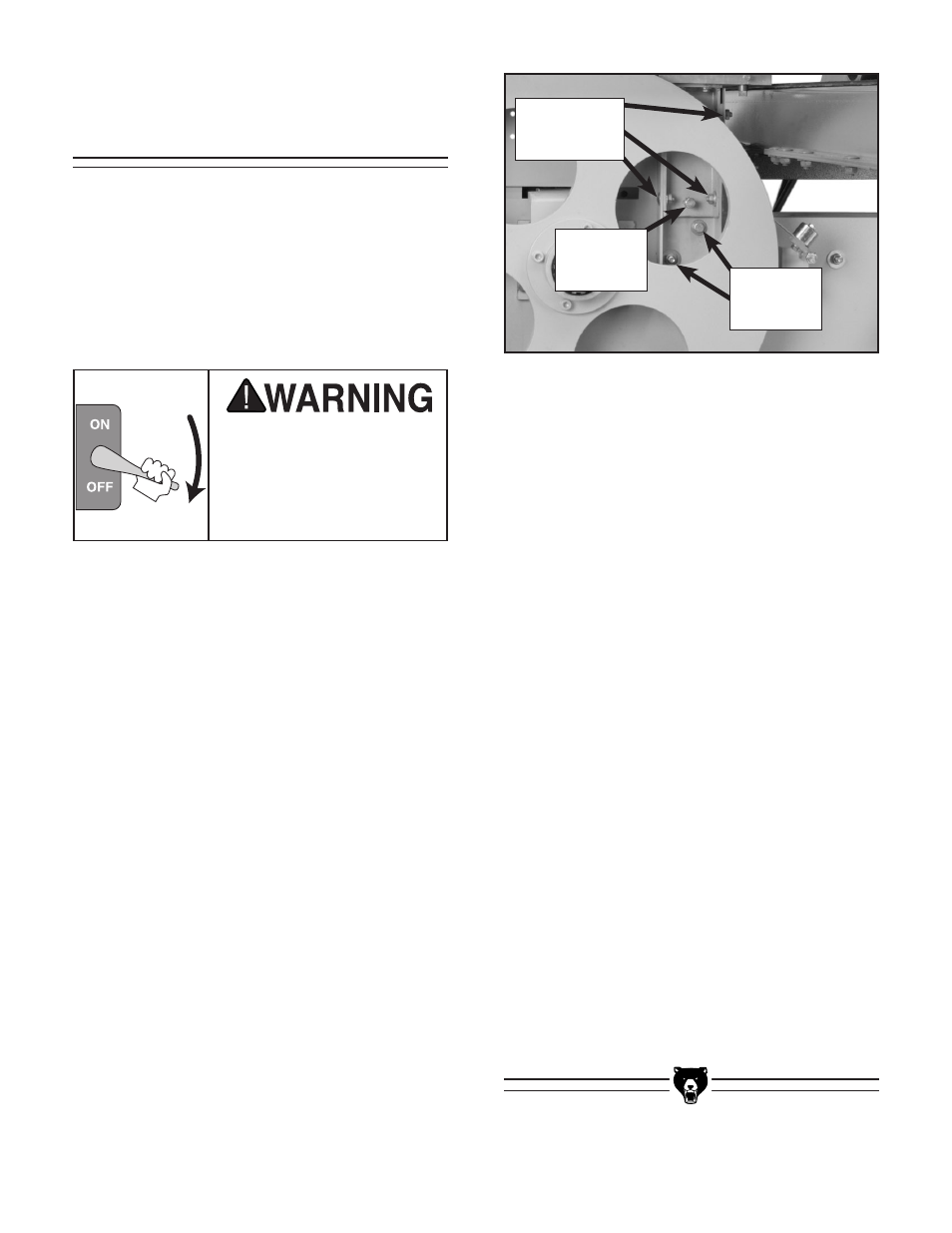

2. loosen the vertical adjustment bolts shown

in

figure 57 if the blade is not centered verti-

cally in the guide slot.

These instructions present

a serious injury hazard if

done while the machine

is connected to power. DO

NOT connect to power until

instructed!

figure 57. guide block adjusting bolts.

(fourth vertical adjustment bolt hidden behind

the wheel in this picture).

3. shift the blade guide adjusting bracket until

the blade is centered in the guide slot.

4. tighten the vertical adjustment bolts and

repeat

step 1.

5. loosen the lower two vertical adjustment

bolts if the blade guide is tilted so the blade

touches the front or back.

6. loosen the lock nut on the tilt adjustment

bolt indicated in

figure 57, and adjust the tilt

adjustment bolt until the guide block is level.

7. tighten the lock nut and the vertical adjust-

ment bolts, and repeat

step 1.

8. loosen the rotation adjustment bolts shown

in

figure 57 if the blade touches the guide

on the right or left sides.

9. rotate the guide block until it is level and

tighten the rotation adjustment bolts.

10. test the alignment as described in step 1.

Continue to make adjustments until the guide

block no longer touches the blade.

11. repeat the previous steps for the other guide

block.

Vertical

adjustment

Bolts

tilt

adjustment

Bolt

rotation

adjustment

Bolts