About service, Tracking – Grizzly G0503 User Manual

Page 42

Model G0503 (Mfg. Since 12/08)

-40-

this section is designed to help the operator with

adjustments that were made at the factory and

that might also need to be made during the life

of the machine.

this section is provided for your convenience—

it is not a substitute for the grizzly service

department. if any adjustments arise that are not

described in this manual, then feel free to call the

grizzly service department at (570) 546-9663.

similarly, if you are unsure of how to perform

any procedure in this section, the grizzly service

department will be happy to guide you through

the procedures or help in any other way.

Always disconnect

power to the machine

before performing ser-

vice adjustments. failure

to do this may result in

serious personal injury.

Power

Source

Locking

Disconnect Switch

Machine

Ground

Ground

Conduit

Conduit

About Service

SEcTION 7: SERvIcE

Tracking

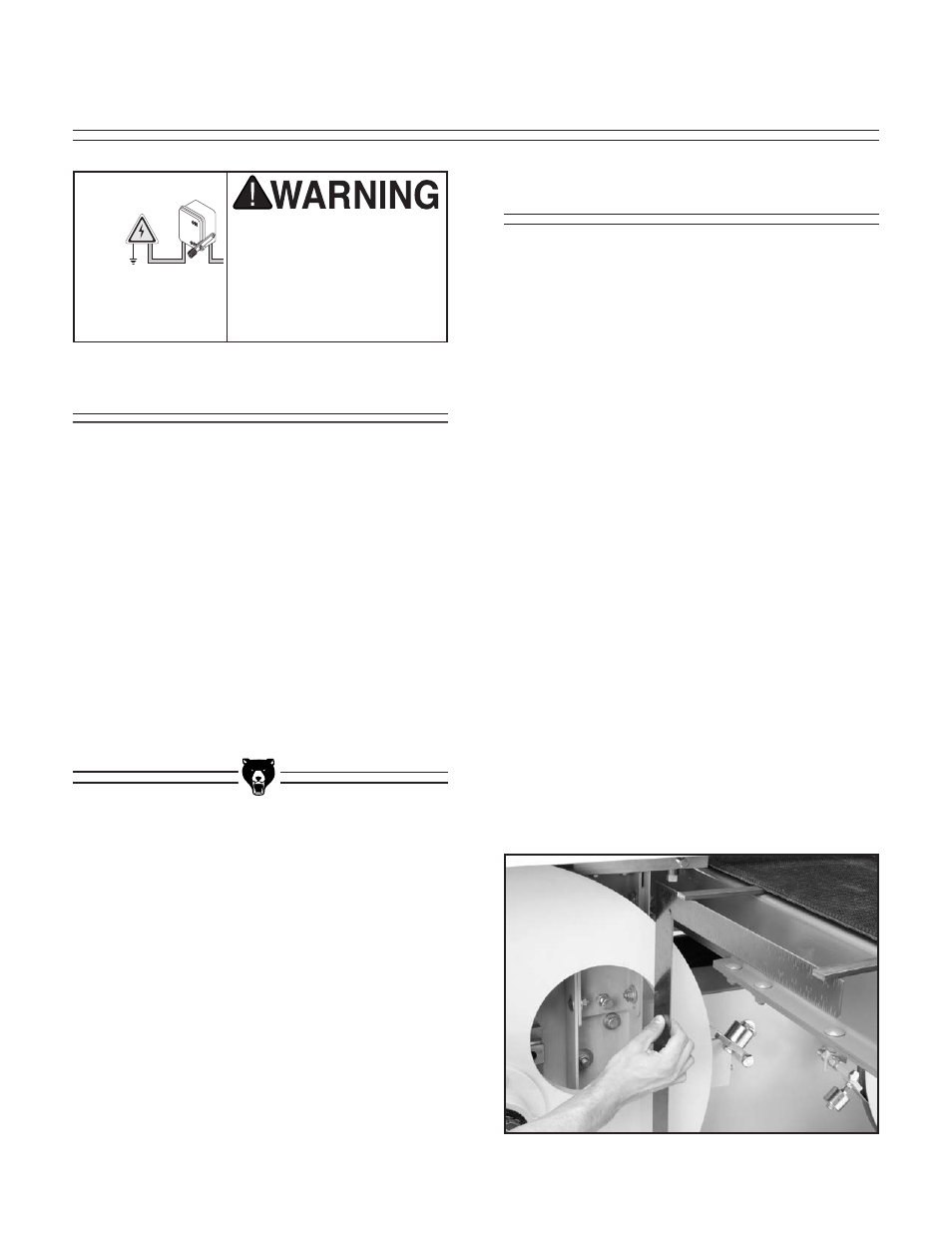

figure 53. Vertical wheel adjustment.

Blade tracking consists of aligning the wheels to

keep the blade centered when the wheel is rotat-

ed under full tension. when replacing blades fine

tuning may be necessary, but this entire process

should not have to be repeated unless the wheels

are removed.

Tools Needed

Qty

straightedge ...................................................... 1

t-handle wrench .............................................. 1

wrench 19mm ................................................... 1

hex wrench 4mm .............................................. 1

To track the blade:

1. Disconnect the resaw from the power

source!

2. Move the blade guides out of the way.

3. turn the wheels by hand. if the bottom of the

blade gullets do not remain approximately

1

⁄

16

" away from the front edge of the wheels,

then adjust the tracking.

4. place two flat bars under the conveyer belt

and place a square against the fixed wheel

as shown in

figure 53. Make note of the

angle between the wheel and the square.