Grizzly G0503 User Manual

Page 39

Model G0503 (Mfg. Since 12/08)

-37-

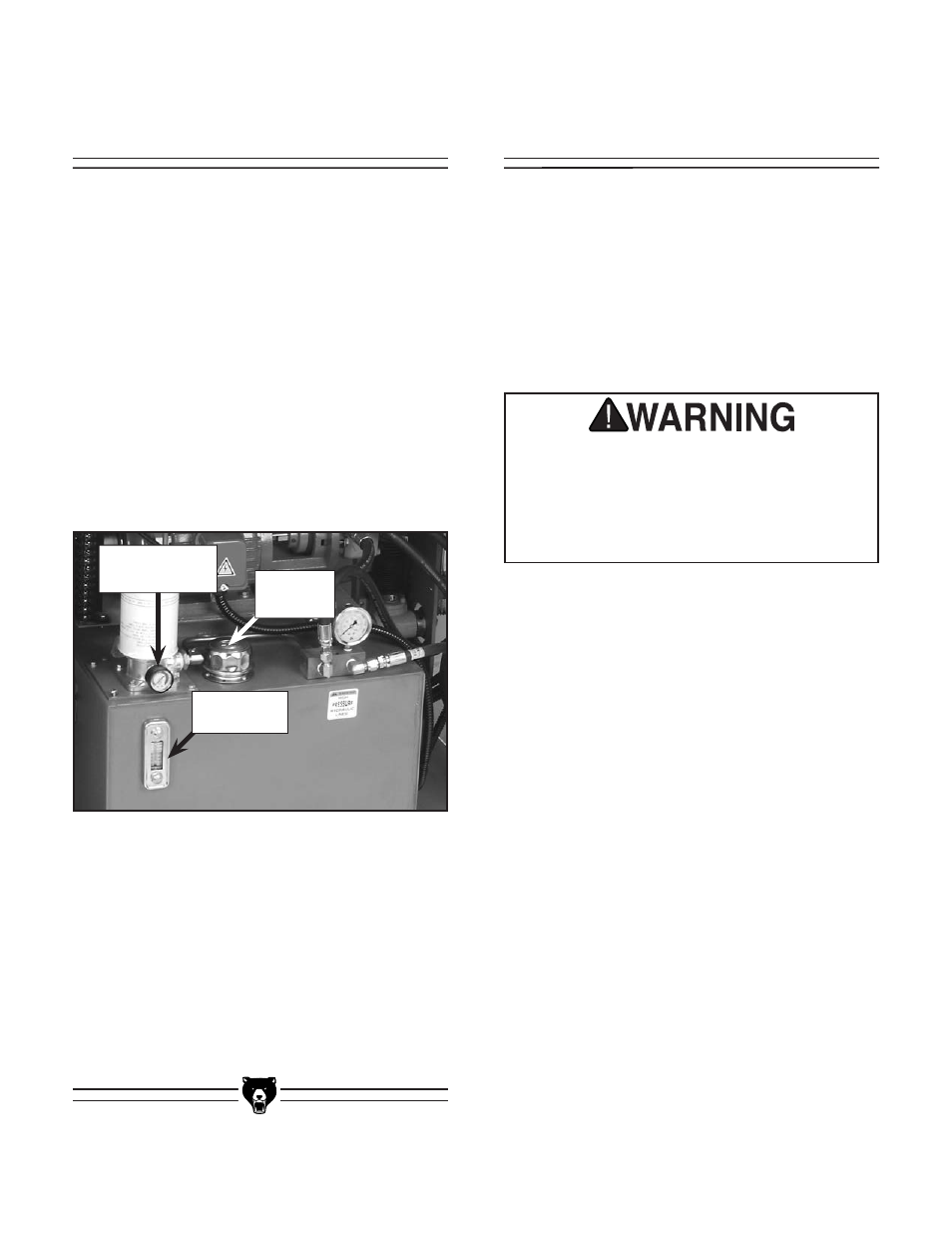

figure 48. hydraulic reservoir components.

in order for the hydraulic system to operate the

conveyor properly and at the correct tempera-

ture, the hydraulic fluid level in the tank should

be

2

⁄

3

full between the fill lines on the fluid sight

window, which is located on the front of the tank

(see

figure 48).

check the hydraulic fluid level daily.

to add hydraulic fluid, wipe the dust and dirt from

the breather cap shown in

figure 48 and remove

the cap. Fill the tank to the full line with an iso

Vg 46 hydraulic fluid. if this machine is used in

extreme cold conditions use iso Vg 32 hydraulic

fluid; use iso Vg 68 hydraulic fluid for extreme

hot environments.

the hydraulic system minor service consists of

changing the filter, cleaning the breather cap and

filler screen, and inspecting the hydraulic fluid for

signs of thermal breakdown, dust contamination,

and water contamination.

perform a “Minor Service” every 960 hours,

or when the filter pressure gauge (see figure

48) nears the red.

Inspect and clean the breather cap and filler

screen every 40 hours of regular use.

Visually inspect both the breather cap and the

plastic screen that sits in the tank opening. if

there is visual contamination, clean both items

with solvent and compressed air. allow them to

completely dry before installing back in the tank.

do not pour hydraulic fluid from the center of

the screen back into the tank.

The hydraulic system on this machine cre-

ates very high pressure and the hydraulic

fluid gets hot. Always stop the resaw, make

sure the pressure gauge reads 0 pSI, and

make sure the fluid cools down before ser-

vicing the hydraulic system.

Hydraulic System

Minor Service

Hydraulic fluid

Schedule

Fluid sight

window

Breather

Cap

To inspect the hydraulic fluid:

1. look at the color of the hydraulic fluid in the

sight window.

— if the fluid is milky in appearance, then the

hydraulic fluid is contaminated with water.

— if the fluid is dark brown or opaque, then

the hydraulic fluid is severely contaminated

or thermal breakdown has occurred.

2. smell the hydraulic fluid (remove breather

cap).

— if the fluid smells rancid or burnt, then the

hydraulic fluid has overheated and ther-

mal breakdown has most likely occurred.

Correct the component that is causing

thermal breakdown (see Troubleshooting

on

page 68).

3. determine what service is needed.

— if the fluid is transparent and does not smell

burnt or rancid, perform a minor service.

— if the fluid is opaque, smells rancid or burnt,

fix the source of contamination or the com-

ponent causing thermal breakdown, then

perform a major service.

Filter pressure

gauge