Resawing, Notice – Grizzly G0503 User Manual

Page 32

Model G0503 (Mfg. Since 12/08)

-30-

Resawing

8. receive the workpiece on the outfeed side

of the machine. note—If a second person is

receiving the workpieces, use the return roll-

ers to send them back to the person on the

infeed side.

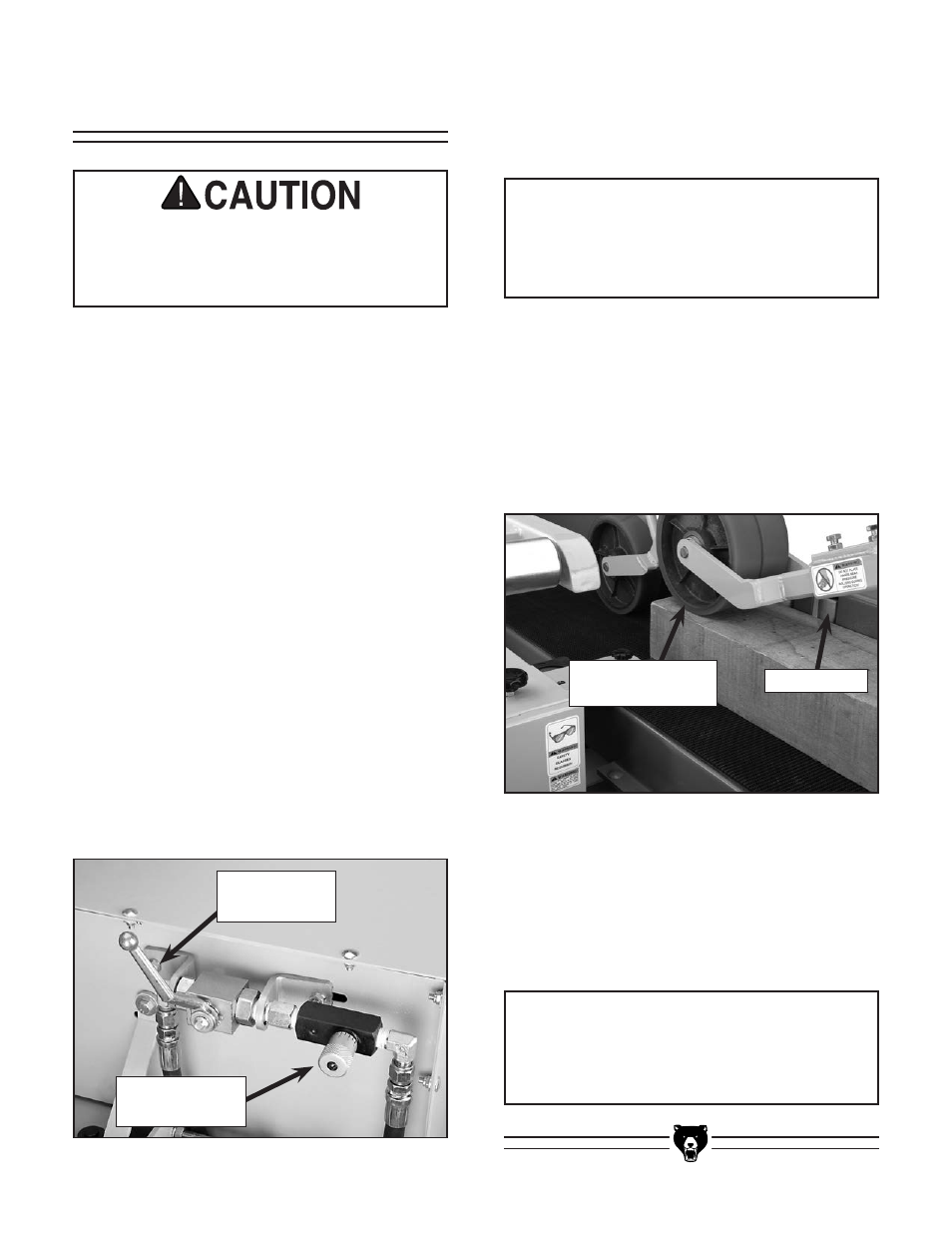

figure 34. Feeding the workpiece

through the bandsaw.

Front pressure

roller assembly

guide roller

figure 33. Conveyor controls.

Variable speed

adjustor

Conveyor on/

oFF lever

5. adjust the conveyor speed with the variable

speed adjustor shown in

figure 33. if the

blade continually rotates the support bear-

ing, reduce the speed of the conveyor.

NOTICE

Always de-tension blade after use. Bandsaw

blades will last longer and stretch less if de-

tensioned after each use.

DO NOT cut slices thinner than

1

⁄

4

" off of

the bottom of the stock. Attempting to cut

thin slices off of the bottom may cause the

blade to cut into the conveyor belt.

To perform a resawing operation:

1. Make sure the blade is installed and ten-

sioned correctly as described in Installing the

Blade on

page 22.

2. set the blade to the desired height.

—to cut off of the top of the stock; place the

stock on the conveyor and align the top of

the blade level with the top of the stock.

remove the stock from the conveyor and

lower the blade the desired amount.

—to cut off of the bottom of the stock; rotate

the handwheel until the blade elevation

gauge reads the desired height. note—Six

rotations of the handwheel raises the blade

approximately

1

/

4

".

3. turn the powEr on switch clockwise to

supply power and press the Motor start

button to start the bandsaw blade.

4. push the puMp start button and move the

conveyor on/oFF lever forward to start the

conveyor belt (see

figure 33).

6. Make sure the workpiece is clean and free of

nails, staples, or embedded stones, and has

two sides that are relatively flat and parallel

with each other.

7. Begin feeding the workpiece under the front

pressure rollers with a flat edge against the

guide rollers, as shown in

figure 34.

NOTICE

Running the conveyor too fast can push the

blade into the support bearing, grooving the

bearing and causing blade breakage.