Reassembly, Eassembly – Goulds Pumps CV 3196 i-FRAME - IOM User Manual

Page 94

Reassembly

Assemble the rotating element and the bearing frame ( STi and MTi )

CAUTION:

Wear insulated gloves when you use a bearing heater. Bearings get hot and can cause physical injury.

NOTICE: Make sure that the pipe threads are clean, and that you apply thread sealant to the plugs and

fittings. Failure to do so may result in equipment damage or decreased performance.

NOTICE: Use an induction heater that heats as well as demagnetizes the bearings when you install

bearings. Failure to do so may result in decreased performance.

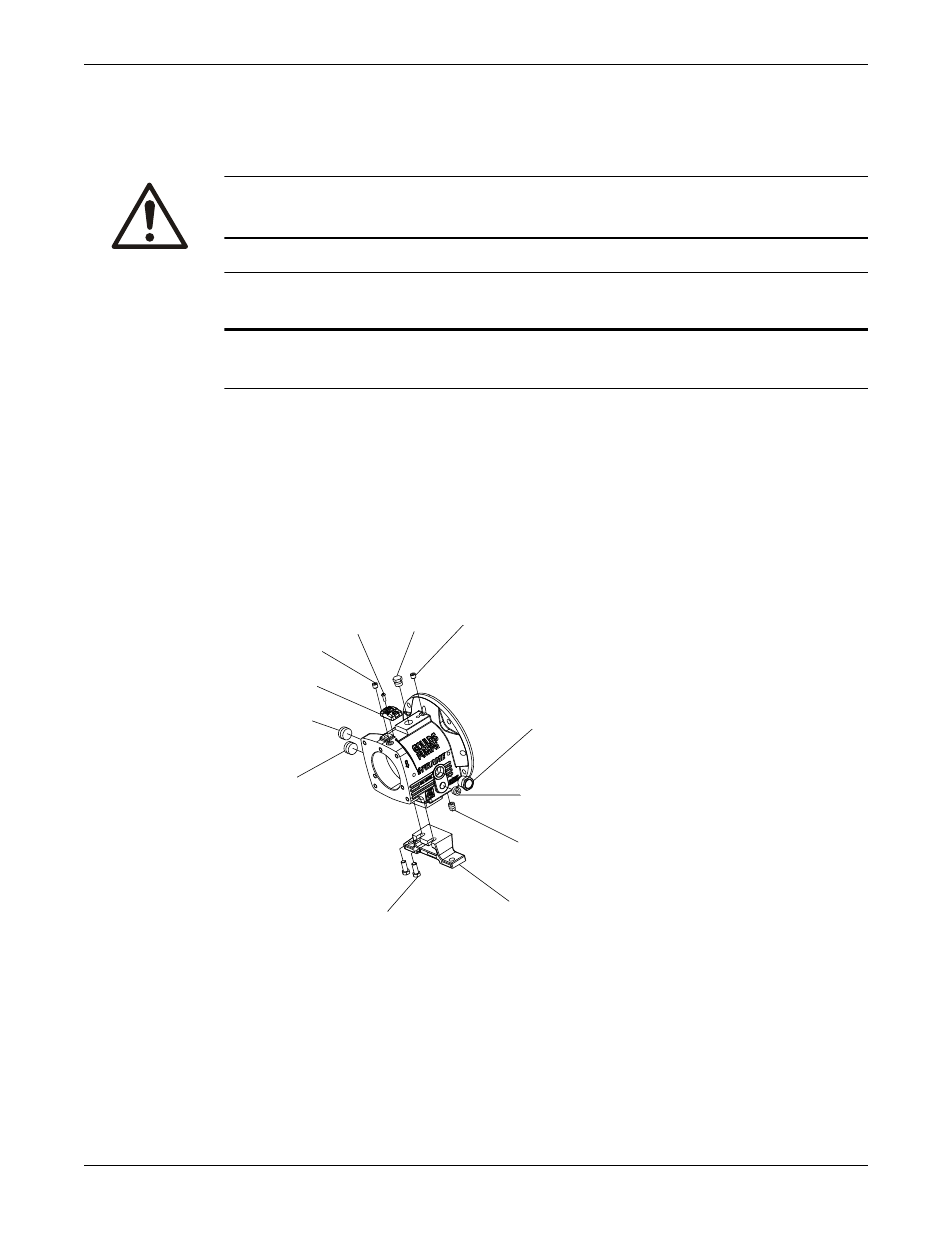

1. Prepare the bearing frame (228) as follows (see the illustration):

a) Install the oil-fill plug (113A).

b) Install the oil-drain plug (408A).

c) Install the sight glass (319).

d) Install the sight oiler plug (408J).

e) Install the plug for the oil-cooler inlet (408L).

f) Install the plug for the oil-cooler outlet (408M).

g) Install four oil-mist connection plugs (408H).

Or: Install two grease fittings (193) and two grease-relief plugs (113).

h) Attach the bearing-frame foot (241) and fasten the bolts (370F) by hand.

319

408N

408A

241

370F

408N

408W

372T

113A

408W

408M

761B

2. Install the outboard bearing (112A) on the shaft (122).

The regreaseable bearing has a single shield. The outboard bearing is installed with the shield toward

the impeller.

a) Inspect the shaft (122) to ensure that it is clean, dimensionally correct, and is free of nicks and

burrs.

b) Lightly coat the bearing seating with a thin film of oil.

c) Remove the bearing (112) from its packaging.

d) Wipe the preservative from the bearing (112) bore and outer diameter.

e) Use an induction heater with a demagnetizing cycle to heat the bearing (112) to an inner ring

temperature of 230 °F (110 °C).

Maintenance

92

Model CV 3196 i-FRAME Installation, Operation, and Maintenance Manual