Guidelines for i-alert™ condition monitor disposal, Disassemble the c-face adapter, Pre-assembly inspections – Goulds Pumps CV 3196 i-FRAME - IOM User Manual

Page 86: Replacement guidelines, Guidelines for i-alert, Condition monitor disposal, Placement guidelines

Guidelines for i-ALERT

™

Condition Monitor disposal

Precautions

WARNING:

• Never heat the condition monitor to temperatures in excess of 300°F (149°C). Heating to these

temperatures could result in death or serious injury.

• Never dispose of the condition monitor in a fire. This could result in death or serious injury.

Guidelines

The battery contained in the condition monitor does not contain enough lithium to qualify as reactive

hazardous waste. Use these guidelines when disposing of the condition monitor.

• The condition monitor is safe for disposal in the normal municipal waste stream.

• Adhere to local laws when you dispose of the condition monitor.

Disassemble the C-face adapter

NOTICE: You must properly support the motor with a clean, uncorroded eye bolt or a strap under both

end bells. Failure to do so may result in equipment damage.

1. Loosen the motor-mounting bolts and remove the motor.

This table shows the number of motor-mounting bolts.

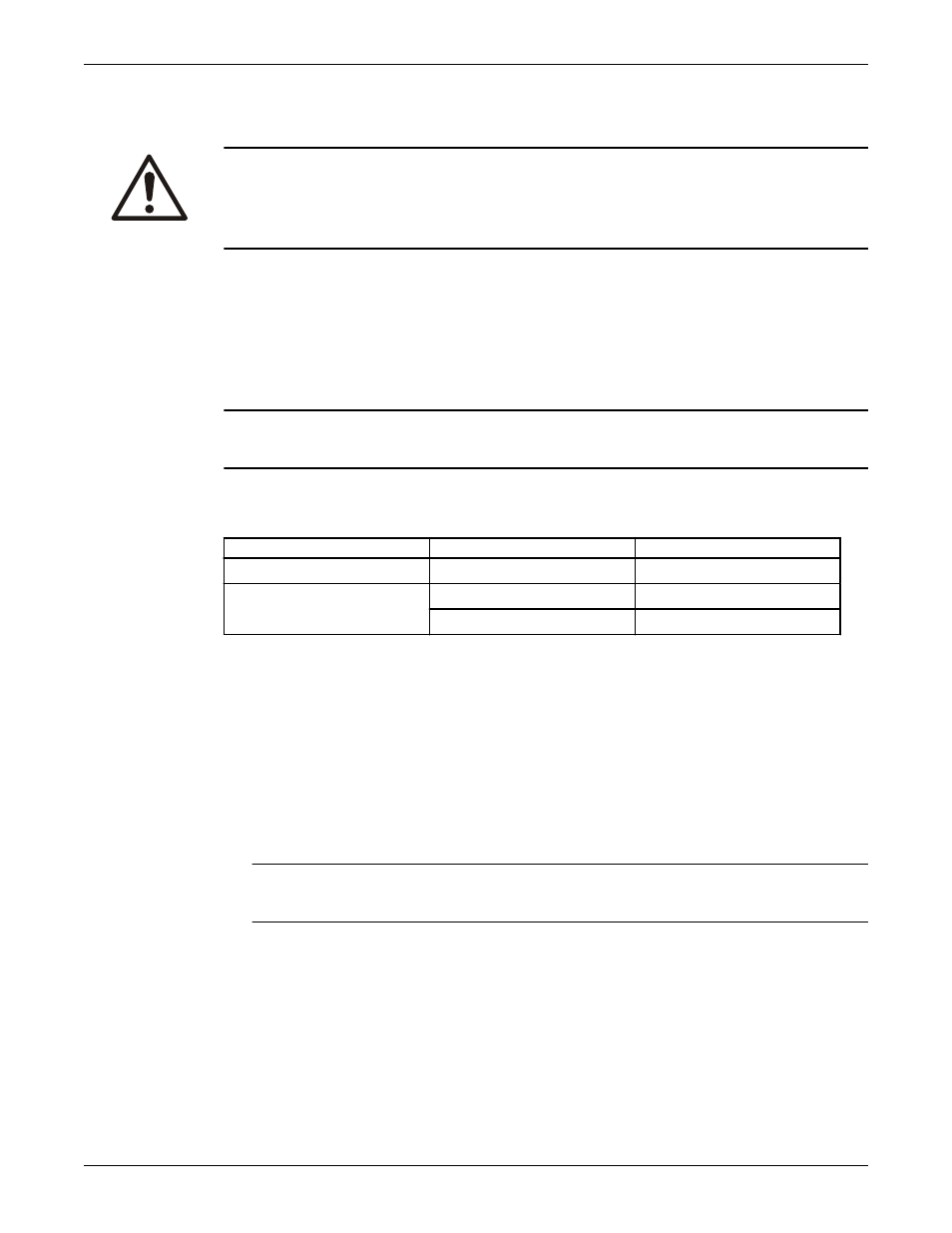

Table 12: Required number of motor-mounting bolts

Pump frame

Motor frame

Number of bolts

STi

All

4

MTi and LTi

143-286

4

324-365

8

2. Loosen the bolts attached to the bearing-frame flange and remove the C-face adapter from the

bearing frame.

Pre-assembly inspections

Guidelines

Before you assemble the pump parts, make sure you follow these guidelines:

• Inspect the pump parts according to the information in these pre-assembly topics before you

reassemble your pump. Replace any part that does not meet the required criteria.

• Make sure that the parts are clean. Clean the pump parts in solvent in order to remove oil, grease, and

dirt.

NOTICE: Protect machined surfaces while you clean the parts. Failure to do so may result in

equipment damage.

Replacement guidelines

Casing check and replacement

Inspect the casing for cracks and excessive wear or pitting. Thoroughly clean gasket surfaces and alignment

fits in order to remove rust and debris.

Repair or replace the casing if you notice any of these conditions:

• Localized wear or grooving that is greater than 1/8 in. (3.2 mm) deep

• Pitting that is greater than 1/8 in. (3.2 mm) deep

• Irregularities in the casing-gasket seat surface

Maintenance

84

Model CV 3196 i-FRAME Installation, Operation, and Maintenance Manual