Bearing maintenance, Lubricating-oil requirements, Oil volumes – Goulds Pumps CV 3196 i-FRAME - IOM User Manual

Page 63: Acceptable oil for lubricating bearings

Bearing maintenance

These bearing lubrication sections list different temperatures of the pumped fluid. If the pump is ATEX-

certified and the temperature of the pumped fluid exceeds the permitted temperature values, then consult

your ITT representative.

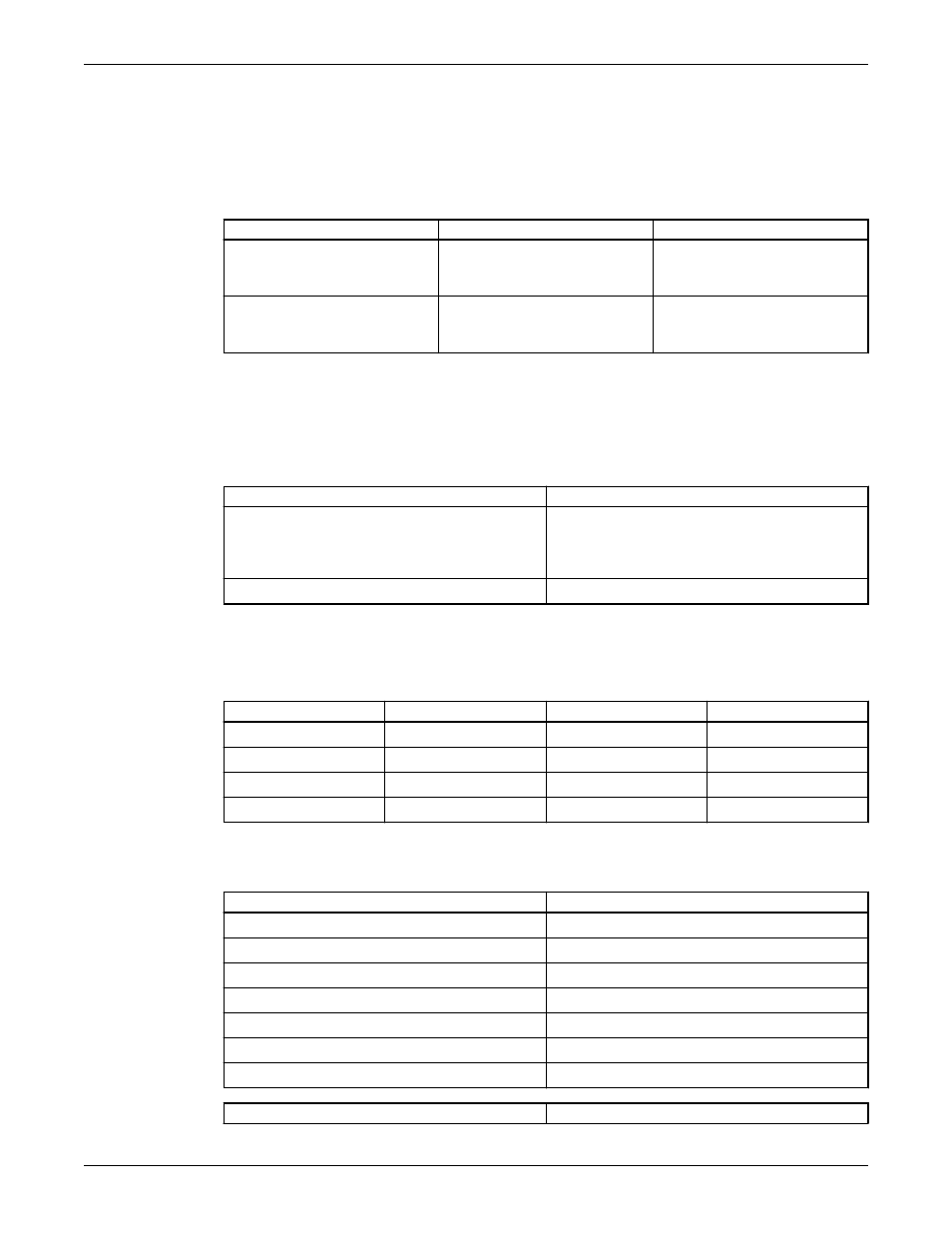

Bearing lubrication schedule

Type of bearing

First lubrication

Lubrication intervals

Oil-lubricated bearings

Add oil before you install and start

the pump. Change the oil after 200

hours for new bearings.

After the first 200 hours, change

the oil every 2000 operating hours

or every three months.

Grease-lubricated bearings

Grease-lubricated bearings are

initially lubricated at the factory.

Regrease bearings every 2000

operating hours or every three

months.

Lubricating-oil requirements

Oil requirements based on temperature

For the majority of operating conditions, bearing temperatures run between 120°F (49°C) and 180°F

(82°C), and you can use an oil of ISO viscosity grade 68 at 100°F (38°C). If temperatures exceed 180°F

(82°C), refer to the table for temperature requirements.

Temperature

Oil requirement

Bearing temperatures exceed 180°F (82°C)

Use ISO viscosity grade 100 with bearing-frame

cooling or finned-tube oil cooler. The finned-tube

oil cooler is standard with the HT 3196 model and

optional for all other models.

Pumped-fluid temperatures exceed 350°F (177°C)

Use synthetic lubrication.

Oil volumes

Oil volume requirements

This table shows the required amount of oil for oil-lubricated bearings.

Frame

Qts.

Oz.

ml

STi

0.5

16

400

MTi

1.5

47

1400

LTi

1.5

48

1400

XLT-i and i17

3

96

3000

Acceptable oil for lubricating bearings

Acceptable lubricants

Brand

Lubricant type

Chevron

GTS Oil 68

Exxon

Teresstic EP 68

Mobil

DTE 26 300 SSU @ 100°F (38°C)

Philips

Mangus Oil 315

Shell

Tellus Oil 68

Sunoco

Sunvis 968

Royal Purple

SYNFILM ISO VG 68 Synthetic Lube

Brand

Lubricant type

Maintenance

Model CV 3196 i-FRAME Installation, Operation, and Maintenance Manual

61