Permitted indicator values for alignment checks, Cold settings for parallel vertical alignment, Alignment measurement guidelines – Goulds Pumps CV 3196 i-FRAME - IOM User Manual

Page 30

Final alignment (hot alignment) checks

When

Why

After the first run

This ensures correct alignment when both the pump and the driver

are at operating temperature.

Periodically

This follows the plant operating procedures.

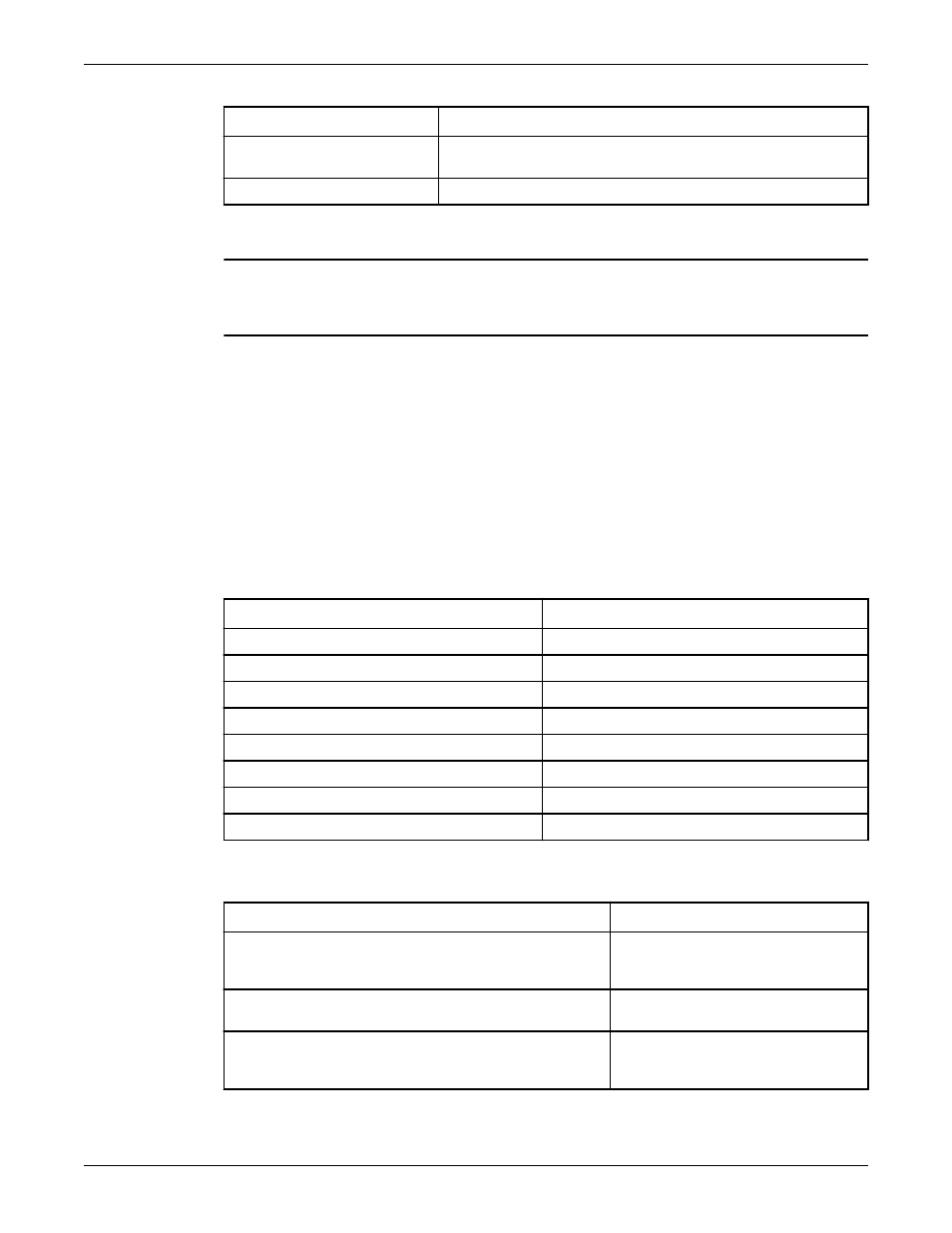

Permitted indicator values for alignment checks

NOTICE: The specified permitted reading values are valid only at operating temperature. For cold

settings, other values are permitted. You must use the correct tolerances. Failure to do so can result in

misalignment and reduced pump reliability.

When dial indicators are used to check the final alignment, the pump and drive unit are correctly aligned

when these conditions are true:

• The total indicator runout is a maximum of 0.002 in. (0.05 mm) at operating temperature.

• The tolerance of the indicator is 0.0005 in./in. (0.0127 mm/mm) of indicator separation at operating

temperature.

Cold settings for parallel vertical alignment

Introduction

This section shows the recommended preliminary (cold) settings for electric motor-driven pumps based on

different temperatures of pumped fluid. Consult driver manufacturers for recommended cold settings for

other types of drivers such as steam turbines and engines.

Recommended settings for models 3196, CV 3196, and LF 3196

Pumpage temperature

Recommended setting

50°F (10°C)

0.002 in. (0.05 mm), low

150°F (65°C)

0.001 in. (0.03 mm), high

250°F (120°C)

0.005 in. (0.12 mm), high

350°F (175°C)

0.009 in. (0.23 mm), high

450°F (218°C)

0.013 in. (0.33 mm), high

550°F (228°C)

0.017 in. (0.43 mm), high

650°F (343°C)

0.021 in. (0.53 mm), high

700°F (371°C)

0.023 in. (0.58 mm), high

Alignment measurement guidelines

Guideline

Explanation

Rotate the pump coupling half and the driver coupling half

together so that the indicator rods have contact with the same

points on the driver coupling half.

This prevents incorrect measurement.

Move or shim only the driver in order to make adjustments.

This prevents strain on the piping

installations.

Make sure that the hold-down bolts for the driver feet are

tight when you take indicator measurements.

This keeps the driver stationary since

movement causes incorrect

measurement.

Installation

28

Model CV 3196 i-FRAME Installation, Operation, and Maintenance Manual