Lubrication conversion, Frame lubrication conversion – Goulds Pumps CV 3196 i-FRAME - IOM User Manual

Page 126

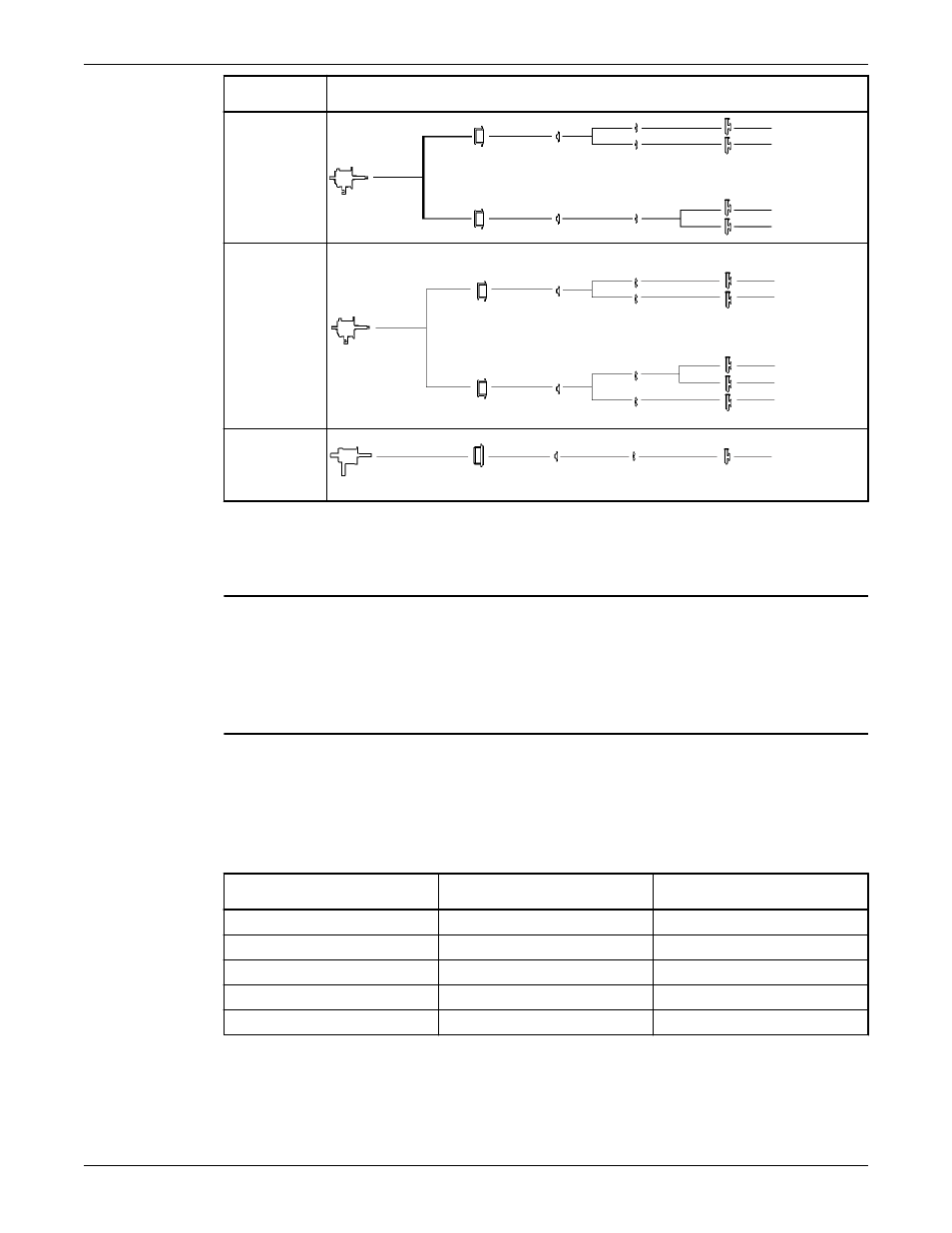

Description

Shaft and Bearing

Frame Assembly

Adapter Seal Chamber Impeller

Casing

Size

Model CV 3196

MTi 1–3/4 in.

Shaft Dia. Max

BHP-122 HP

2x2-10

3x3-10

2x3-13

3x4-13

Model CV 3196

LTi 2–1/8 in.

Shaft Dia. Max

BHP-200 HP

2x2-10

3x3-10

2x3-13

3x4-13

4x6-13

Model CV 3196

XLT-I 2–1/2 in.

Shaft Dia. Max

BHP-250 HP

6x8-15

Lubrication conversion

Frame lubrication conversion

NOTICE:

• Never mix greases of different consistencies (NLGI 1 or 3 with NLGI 2) or with different thickeners.

For example, never mix a lithium-based grease with a polyurea-based grease. Doing so may result in

decreased performance.

• Remove the bearings and old grease if you need to change the grease type or consistency. Failure to

do so may result in equipment damage or decreased performance.

Use a grease that is suitable for high temperatures when you have frame pumpage temperatures greater

than 350°F (177°C). Ensure that mineral-oil greases have oxidation stabilizers and a consistency of NLGI

3.

Most pumps use Sunoco 2EP grease. High temperature units with a pumpage temperature greater than

350° F (177°C) use Mobil SCH32.

This table shows which brand of grease to use when lubricating the pump.

Table 23: Lubricating-grease requirements

Pumpage temperature less than

350°F (177°C)

Pumpage temperature greater

than 350°F (177°C)

NGLI consistency

2

3

Mobil

Mobilux EP2

SCH32

Exxon

Unirex N2

Unirex N3

Sunoco

Mutipurpose 2EP

N/A

SKF

LGMT 2

LGMT 3

Convert from greased-for-life or regreaseable to oil-lubricated bearings

1. Remove the plug from the oil-return slot in the frame located under the radial bearing. Use this table

as a guide.

Maintenance

124

Model CV 3196 i-FRAME Installation, Operation, and Maintenance Manual