I-alert™ condition monitor routine operation, Pump operation precautions, I-alert – Goulds Pumps CV 3196 i-FRAME - IOM User Manual

Page 59: Condition monitor routine operation

i-ALERT

™

Condition Monitor routine operation

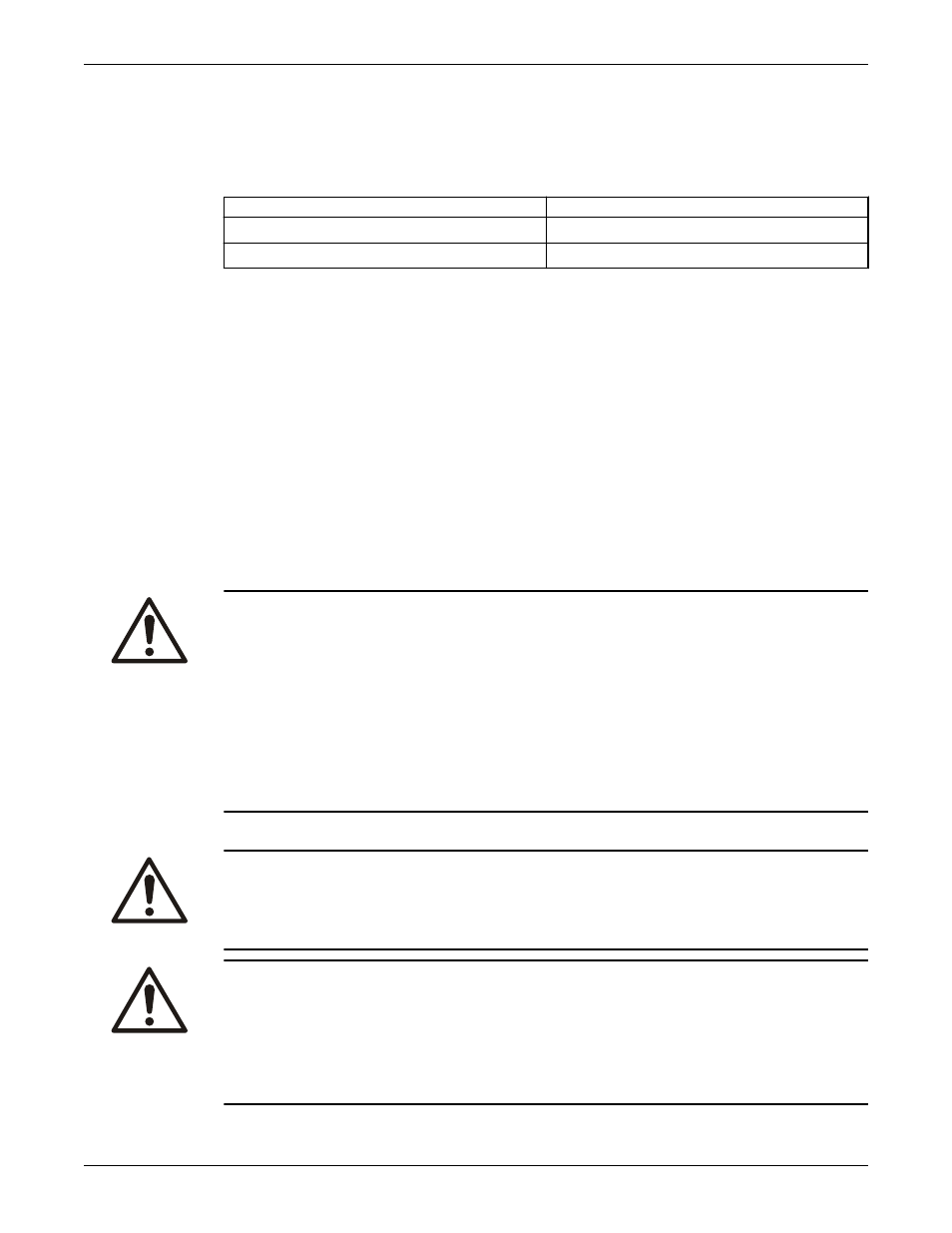

Measurement interval

This table shows the measurement intervals for the condition monitor during normal operation and when

the monitor is in alarm mode.

Mode

Measurement interval

Normal operating mode

Five minutes

Alarm mode

Two minutes

When the condition monitor measures a reading beyond the specified temperature and vibration limits, the

appropriate red LED flashes. After the process or pump condition that causes the alarm is corrected, the

condition monitor returns to normal mode after one normal-level measurement.

Alarm mode

When the condition monitor is in alarm mode, you should investigate the cause of the condition and make

necessary corrections in a timely manner.

Magnetic device considerations

Be careful when you use magnetic devices in close proximity of the condition monitor, such as magnetic

vibration-monitoring probes or dial indicators. These magnetic devices can accidentally activate or

deactivate the condition monitor resulting in improper alarm levels or loss of monitoring.

Pump operation precautions

General considerations

CAUTION:

• Vary the capacity with the regulating valve in the discharge line. Never throttle the flow from the

suction side since this can result in decreased performance, unexpected heat generation, and

equipment damage.

• Do not overload the driver. Driver overload can result in unexpected heat generation and equipment

damage. The driver can overload in these circumstances:

• The specific gravity of the pumped fluid is greater than expected.

• The pumped fluid exceeds the rated flow rate.

• Make sure to operate the pump at or near the rated conditions. Failure to do so can result in pump

damage from cavitation or recirculation.

Operation at reduced capacity

WARNING:

Never operate any pumping system with a blocked suction and discharge. Operation, even for a brief

period under these conditions, can cause confined pumped fluid to overheat, which results in a violent

explosion. You must take all necessary measures to avoid this condition.

CAUTION:

• Avoid excessive vibration levels. Excessive vibration levels can damage the bearings, stuffing box or

seal chamber, and the mechanical seal, which can result in decreased performance.

• Avoid increased radial load. Failure to do so can cause stress on the shaft and bearings.

• Avoid heat build-up. Failure to do so can cause rotating parts to score or seize.

• Avoid cavitation. Failure to do so can cause damage to the internal surfaces of the pump.

Commissioning, Startup, Operation, and Shutdown

Model CV 3196 i-FRAME Installation, Operation, and Maintenance Manual

57