Fastening, Suction-piping checklist – Goulds Pumps CV 3196 i-FRAME - IOM User Manual

Page 37

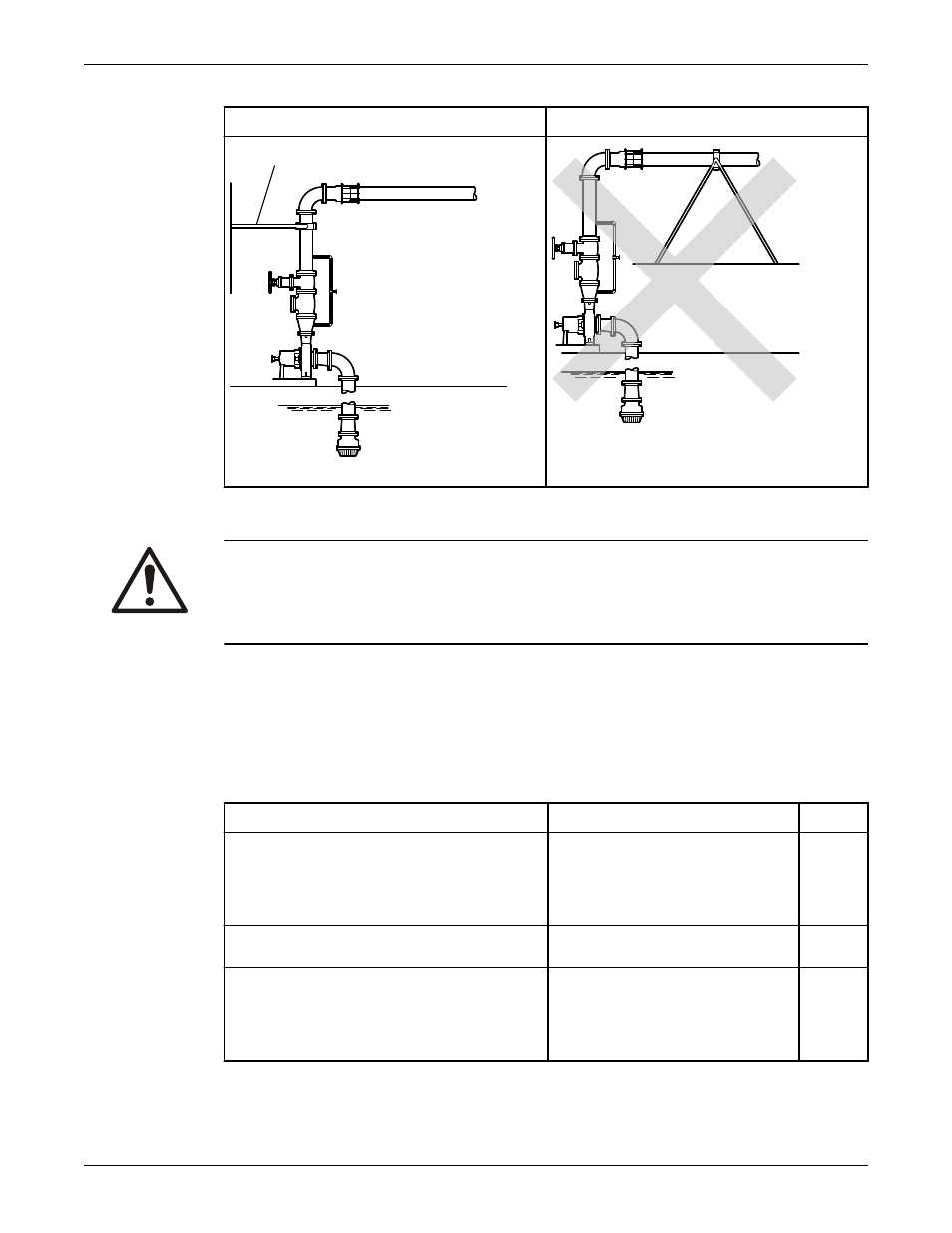

Example: Installation for expansion

Correct

Incorrect

1

1.

Expansion loop/joint

Fastening

WARNING:

• Only use fasteners of the proper size and material.

• Replace all corroded fasteners.

• Make sure that all fasteners are properly tightened and that there are no missing fasteners.

Suction-piping checklist

Performance curve reference

Net positive suction head available (NPSH

A

) must always exceed NPSH required (NPSH

R

) as shown on

the published performance curve of the pump.

Suction-piping checks

Check

Explanation/comment

Checked

Check that the distance between the inlet flange of

the pump and the closest elbow is at least five pipe

diameters.

This minimizes the risk of cavitation in

the suction inlet of the pump due to

turbulence.

See the Example sections for

illustrations.

Check that elbows in general do not have sharp

bends.

See the Example sections for

illustrations.

Check that the suction piping is one or two sizes

larger than the suction inlet of the pump.

Install an eccentric reducer between the pump inlet

and the suction piping.

The suction piping must never have a

smaller diameter than the suction inlet

of the pump.

See the Example sections for

illustrations.

Installation

Model CV 3196 i-FRAME Installation, Operation, and Maintenance Manual

35