B. intellifire plus™ ignition system – Heat & Glo Fireplace Heat & Glo Fireplace 6000C User Manual

Page 69

Heat & Glo • 6000C, 6000C-IPI, 8000C, 8000C-IPI • 2164-900 Rev. T • 9/12

69

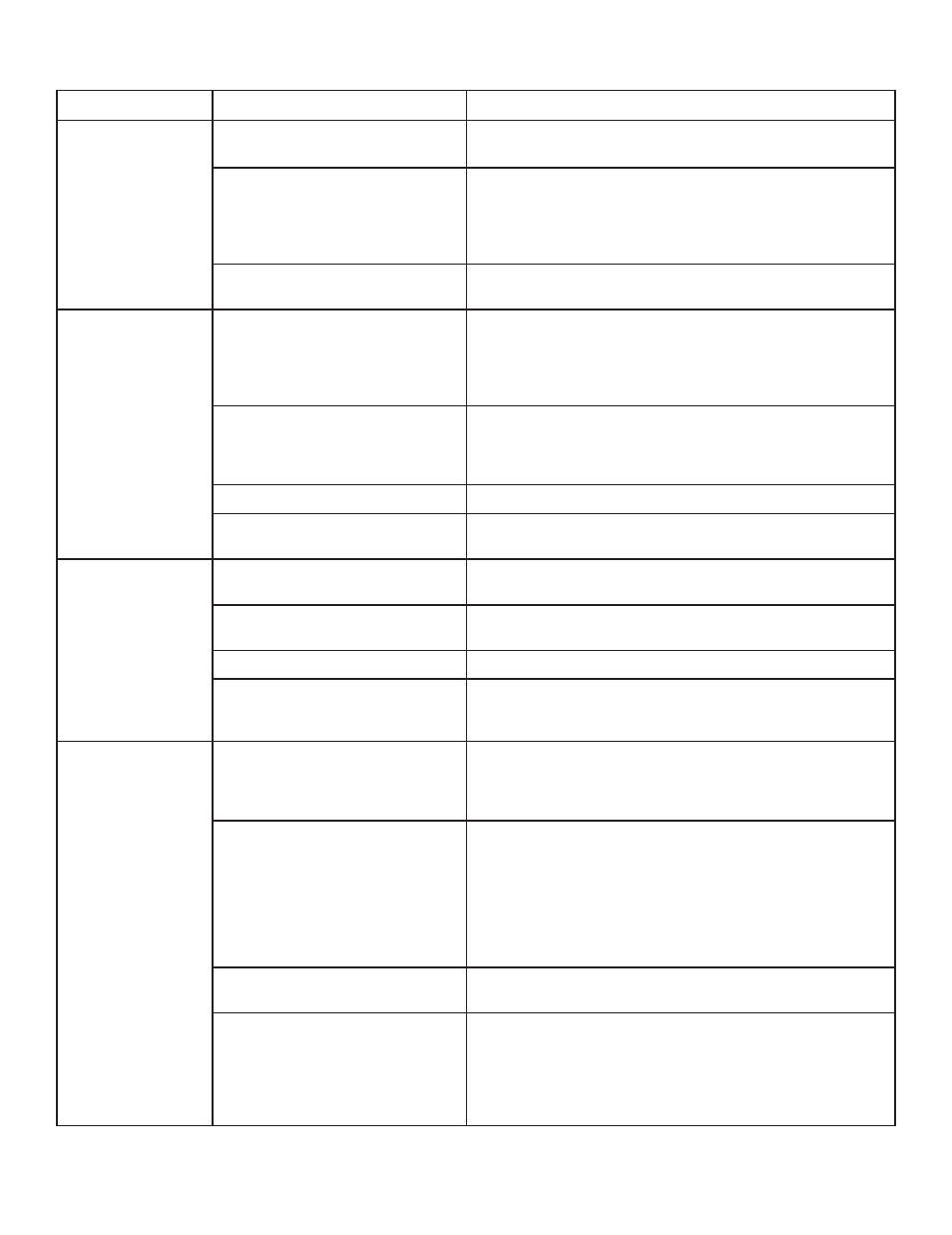

B. IntelliFire Plus™ Ignition System

Symptom

Possible Cause

Corrective Action

1. Pilot won’t light.

The ignitor/module

makes noise, but no

spark.

A. Incorrect wiring.

Verify “S” wire (white) for sensor and “I” wire (orange) for ignitor are

connected to correct terminals on module and pilot assembly.

B. Loose connections or electrical

shorts in the wiring.

Verify no loose connections or electrical shorts in wiring from mod-

ule to pilot assembly. Verify connections underneath pilot assembly

are tight; also verify igniter and flame sense wires are not grounding

out to metal chassis, pilot burner, pilot enclosure, mesh screen if

present, or any other metal object.

C. Ignitor gap is too large.

Verify gap of igniter to right side of pilot hood. The gap should be

approximately .17 in. or 1/8 in. (3 mm).

2. Pilot won’t light,

there is no noise or

spark.

A. No power, transformer installed

incorrectly, or depleted batteries.

Verify that transformer is installed and plugged into module. Check

voltage of transformer at connection to module. Acceptable read-

ings of a good transformer are between 6.4 and 6.6 volts AC. Bat-

tery power supply voltage must be at least 4 volts. If below 4 volts,

replace batteries.

B. A shorted or loose connection in

wiring configuration or wiring har-

ness.

Remove and reinstall the wiring harness that plugs into module.

Verify there is a tight fit. Verify pilot assembly wiring to module. Re-

move and verify continuity of each wire in wiring harness. Replace

any damaged components.

C. Improper wall switch wiring.

Verify that 110/VAC power is “ON” to junction box.

D. Module not grounded.

Verify black ground wire from module wire harness is grounded to

metal chassis of appliance.

3. Pilot sparks, but

Pilot will not light.

A. Gas supply.

Verify that incoming gas line ball valve is “open”. Verify that inlet

pressure reading is within acceptable limits.

B. Ignitor gap is too large.

Verify gap of igniter to right side of pilot hood. The gap should be

approximately .17 in. or 1/8 in. (3 mm).

C. Module is not grounded.

Verify module is securely grounded to metal chassis of appliance.

D. Pilot valve solenoid

Verify that 1.5 to 1.8 VDC is supplied to pilot solenoid from module.

If below 1.5 volts, replace module. If 1.5 volts or greater, replace

valve.

4. Pilot lights but con-

tinues to spark, and

main burner will not

ignite. (If the pilot

continues to spark

after the pilot flame

has been lit, flame

rectification has not

occurred.)

A. A shorted or loose connection in

flame sensing rod.

Verify all connections to wiring diagram in manual. Verify connec-

tions underneath pilot assembly are tight. Verify flame sense or ig-

niter wires are not grounding out to metal chassis, pilot burner, pilot

enclosure or screen if present, or any other metal object.

B. Poor flame rectification or contami-

nated flame sensing rod.

With fixed glass assembly in place, verify that flame is engulfing

flame sensing rod on left side of pilot hood. Flame sensing rod

should glow shortly after ignition. With a multi-meter, verify that

current in series between module and sense lead is at least 0.14

microamps. Verify correct pilot orifice is installed and gas inlet is set

to pressure specifications. Polish flame sensing rod with fine steel

wool to remove any contaminants that may have accumulated on

flame sensing rod.

C. Module is not grounded.

Verify module is securely grounded to metal chassis of appliance.

Verify that wire harness is firmly connected to the module.

D. Damaged pilot assembly or con-

taminated flame sensing rod.

Verify that ceramic insulator around the flame sensing rod is not

cracked, damaged, or loose. Verify connection from flame sensing

rod to white sensor wire. Polish flame sensing rod with fine steel

wool to remove any contaminants that may have accumulated on

flame sensing rod. Verify continuity with a multi-meter with ohms set

at lowest range. Replace pilot if any damage is detected.