Henny Penny PRESSURE FRYERS 600 User Manual

Page 44

Model 500/600

3-20

1207

The following steps will help prevent filter pump problems:

1. Make certain the charcoal filter is installed with the smooth

side down and the arms on the frame are clamped down over

the protrusions on the outside of the frame.

2. The filter valve is to be closed at all times during frying.

3. Pump all the shortening from the filter lines by running the filter

pump motor until the shortening in the frypot appears to be

bubbling or boiling.

3-10. CHANGING THE

FILTER ENVELOPE

The filter envelope should be changed after 10-12 filterings or when-

ever it becomes clogged with crumbs. Proceed as follows:

1. Move the main power switch to the OFF position.

2. Remove and empty the condensation drain pan.

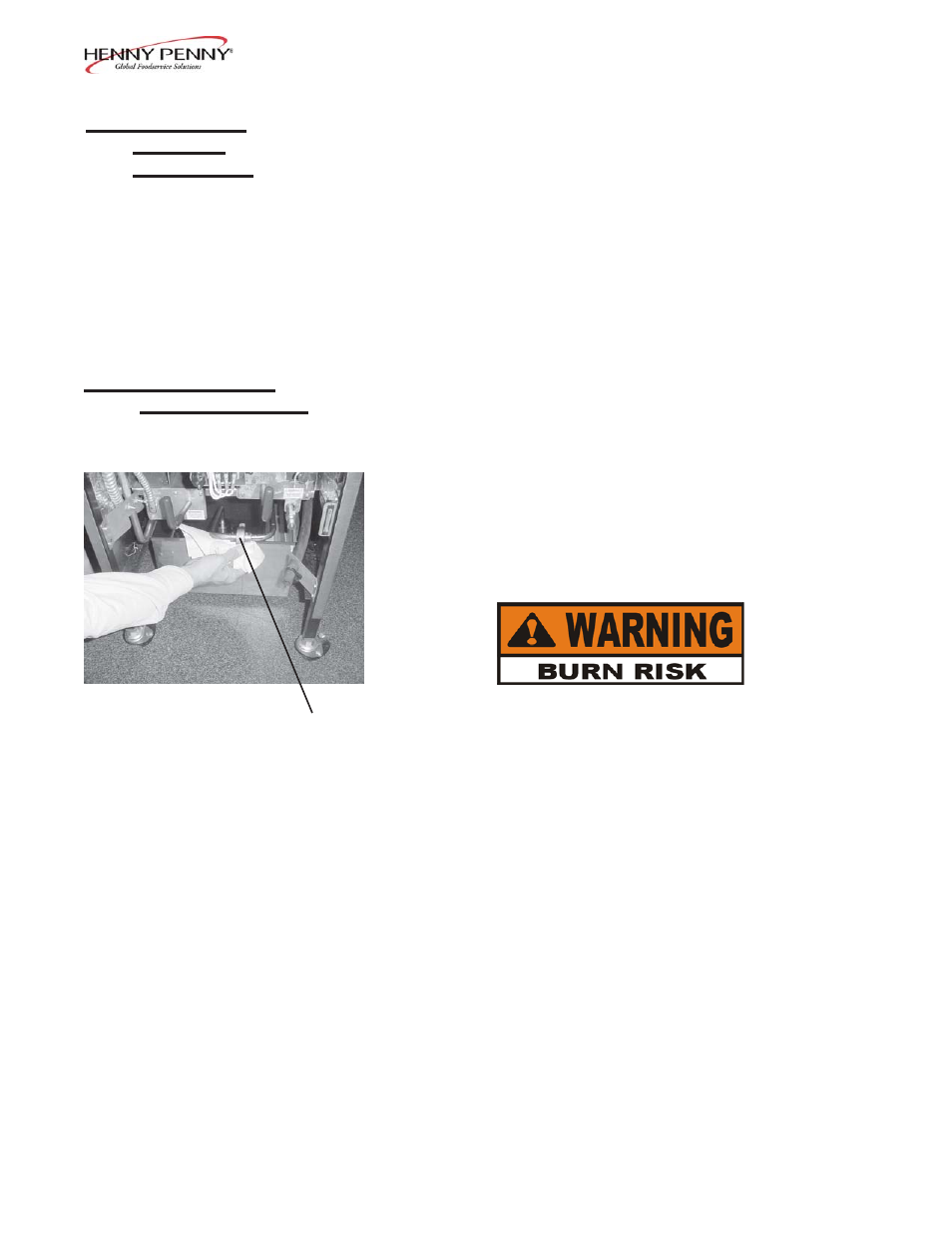

3. Disconnect the filter union and remove the drain pan from

under the frypot. If available, a drain pan may have casters

under it, allowing easy transport of filter pan and filter

assembly.

This union could be hot! Use protective cloth or glove,

or severe burns could result.

If the filter pan is moved while full of shortening, use

care to prevent splashing, or burns could result.

4. Lift the screen assembly from the drain pan.

5. Wipe the shortening and crumbs from the drain pan. Clean

the drain pan with soap and water, then thoroughly rinse with

hot water.

Step 3

3-9. FILTER PUMP

PROBLEM

PREVENTION

Filter Union