Hoshizaki KM-151BAH User Manual

Page 22

17

2) Move the control switch to the “ICE” position and check for proper control voltage. If

the “POWER OK” LED is on, the control voltage is good. If the “POWER OK” LED

is off, check the control transformer circuit. If no voltage is present, check the power

supply circuit.

3) To perform a relay sequence test, turn on the power switch while pressing the

"OUTPUT TEST" button. The correct lighting sequence should be 5, 6, 7, 8, 4.

Some components (e.g., the compressor) will cycle during test. Each LED comes on

for 5 seconds. LED 5 is on while LED 6 is on. Following the output test sequence,

the icemaker will resume normal operation beginning with the 1 minute fill cycle.

[e] CONTROL BOARD REPLACEMENT

The dip switches should be adjusted to the factory default settings as outlined in this

manual. S2 dip switch 5 must remain off.

4. HARVEST CONTROL - THERMISTOR

A thermistor (semiconductor) is used as a harvest control sensor and anti-slush sensor.

The resistance varies depending on the suction line temperatures. The thermistor

detects the temperature of the evaporator outlet to start the harvest timer or momentarily

stop the pump motor during the freeze cycle. No adjustment is required. If necessary,

check for resistance between thermistor leads, and visually check the thermistor

mounting, located on the suction line next to the evaporator outlet.

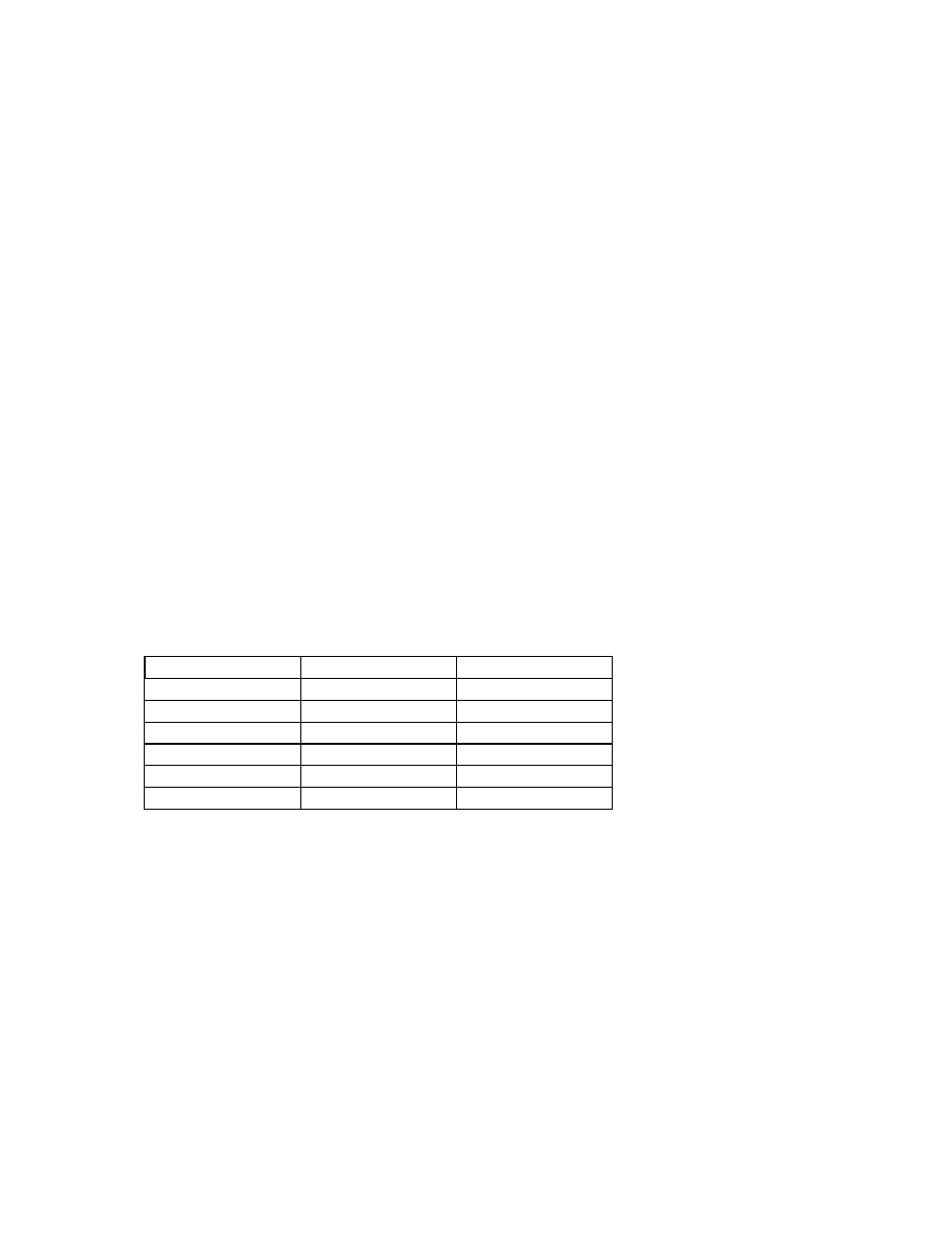

Temperature (°F)

Temperature (°C)

Resistance (kΩ)

0

-18

14.401

10

-12

10.613

32

0

6.000

50

10

3.871

70

21

2.474

90

32

1.633

Check a thermistor for resistance by using the following procedure:

1) Disconnect the connector K1 on the board.

2) Remove the thermistor. See “V. 14. THERMISTOR”.

3) Immerse the thermistor sensor portion in a glass containing ice and water for 2 or 3

minutes.

4) Check for resistance between the thermistor leads. Normal reading is within 3.5 to 7

kΩ. Replace the thermistor if it exceeds the normal reading.