5 gear, 6 motion timebase (realtime vs. synchronized) – Emerson P/N 400361-00 User Manual

Page 42

28 www.emersonct.com SM-EZMotion Module User Guide

Figure 50:

Timed Index Profile

In some cases, an index time is calculated based on other

parameters in a user program. To avoid possible machine

damage, the user can specify maximum values for accel,

velocity, and decel. Therefore, when the SM-EZMotion

firmware calculates accel, velocity, decel, they will never

exceed the maximum values specified by the user, In this

case, where the calculation is limited by a maximum value,

the index will not finish in the specified time. If this

happens, a parameter called Index.ProfileLimited will

activate. It will remain active until cleared by the

Index.ResetProfileLimited destination.

5.5 Gear

The Gear motion profile is used to slave the motion of the

motor to the motion of a master axis at a specified ratio.

Gearing is often referred to as "electronic line shafting" or

"electronic gearing". To gear a follower axis to a master

axis, a ratio (called the gear ratio) must be specified. The

Gear Ratio defines the relationship between the master

and follower motion.

The ratio is calculated as follows:

The ratio is the number of follower distance units to move

the motor per master distance unit of travel. Follower

Distance Units are configured on the User Units view.

Master Distance Units are configured on the Master Setup

screen.

The gear ratio can be positive or negative and is a signed

32-bit parameter. The resolution of the parameter is

determined by the number of decimal places configured for

the Master Velocity Units on the Master Setup screen.

By default, gearing does not use acceleration or

deceleration ramps with respect to the master encoder.

This means that once gearing is activated, peak torque is

available to try to achieve the specified gear ratio.

Therefore, if the master axis is in motion when gearing is

activated, the control loop will attempt to achieve the

programmed ratio within one update without programmed

acceleration. Analogously, when gearing is deactivated,

the motor will use peak torque to bring the motor to a stop

without a deceleration ramp.

Acceleration and Deceleration ramps can be enabled by

the user. If enabled, the Accel and Decel ramps are

specified in units of Follower Units / Velocity Time Base /

Acceleration Time Base. Note that this is a Realtime ramp.

Therefore, the time that it takes to reach the programmed

ratio depends on how fast the master is traveling when

gearing is activated.

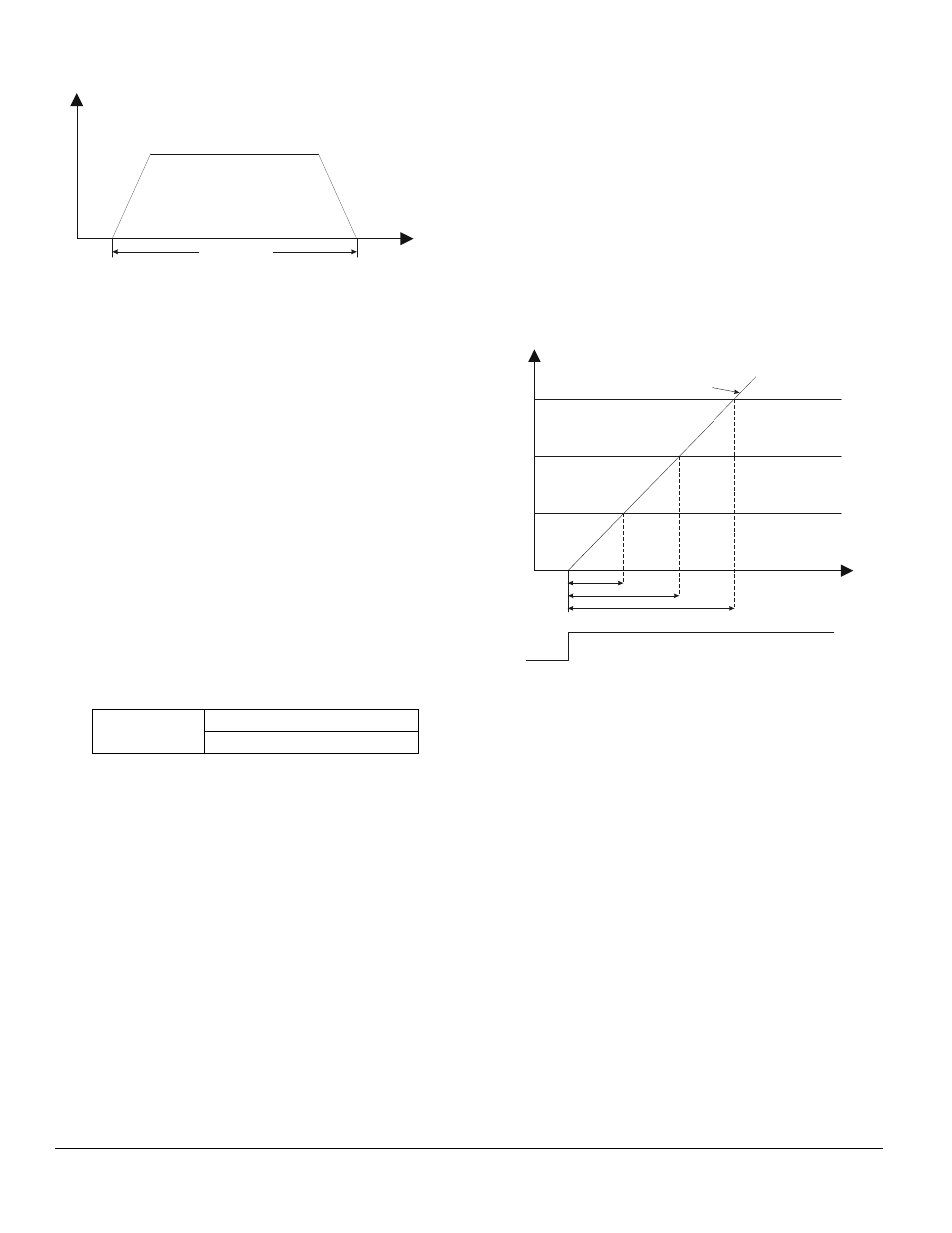

Figure 51 demonstrates that the faster the Master Velocity,

the longer it will take to reach the programmed ratio. If the

Master Axis is not moving when gearing is initiated, then

the follower locks into its programmed gear ratio instantly

(no acceleration time required).

Figure 51:

Gear Acceleration Diagram

The GearRatio can be changed on the fly (while gearing is

active and in motion), but acceleration or deceleration must

be enabled to use ramps to achieve the new ratio. If

gearing accel and/or decel ramps are not enabled, the

motor will attempt to achieve the new ratio in one trajectory

update.

5.6 Motion Timebase (Realtime

vs. Synchronized)

The Timebase for a profile determines what parameter is

used as the denominator for velocity and acceleration

units. The default Timebase for all motion types (other than

gear) is Realtime.

A Timebase of Realtime specifies that the denominator for

velocity and acceleration units are units of actual time:

Minutes, Seconds, or Milliseconds (defined on the User

Units View). Therefore, units of velocity for a realtime

Gear Ratio =

# of Follower Distance Units

1 Master Distance Unit

Velocity

Index Accel

2 Seconds

Time

T

1

Programmed

Gear Accel Rate

T

2

T

3

MV

3

MV

2

MV

1

Velocity

Time

T < T < T = The greater the master velocity (MV) the

longer it takes to accelerate to the Gear Ratio.

1

2

3

Gear

Initiate