Spectrum Controls 1756sc-IF8u User Manual

Page 27

Chapter 2: Installing And Wiring Your Module

15

• Keep all unshielded wires as short as possible.

• To limit overall cable impedance, keep input cables as short as possible.

Locate your I/O chassis as near the RTD or thermocouple sensors as

your application will permit.

• Tighten screw terminals with care. Excessive tightening can strip a

screw. The RTB terminations can accommodate 2.1…0.25 mm2

(14…22 AWG) shielded wire and a torque of 0.5 N•m (4.4 lb•in.).

• Follow system grounding and wiring guidelines found in your

ControlLogix Installation and Operation Manual.

Preparing and

Wiring the Cables

To prepare and connect cable leads and drain wires, follow these steps:

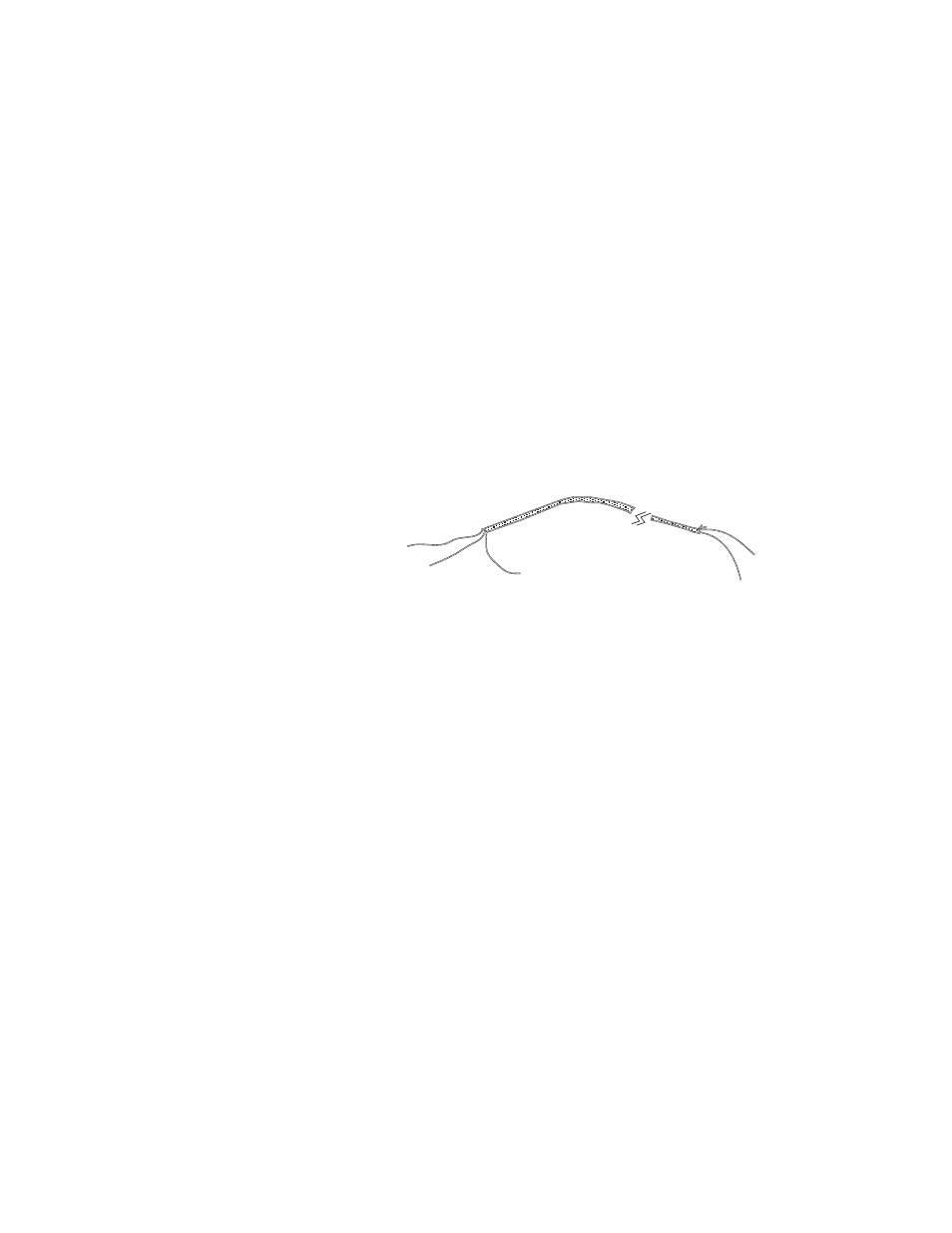

Signal Wires

Drain Wire

Signal Wires

Cable

(Remove foil shield and drain wire

from sensor-end of the cable.)

(At the module-end of the cable, extract

the drain wire but remove the foil shield.)

1. At each end of the cable, strip some casing to expose individual wires.

2. Trim signal wires to 5-inch lengths beyond the cable casing. Strip about

3/16 inch (4.76 mm) of insulation to expose the ends of the wires.

3. At the module-end of the cables (see figure above):

- extract the drain wire and signal wires

- remove the foil shield

- bundle the input cables with a cable strap

4. Connect pairs of drain wires together, Channels 0 and 1, Channels 2

and 3, Channels 4 and 5, Channels 6 and 7. Keep drain wires as short

as possible.

5. Connect the drain wires to the grounding lug on the PLC chassis.

6. Connect the signal wires of each channel to the terminal block.

Important: Only after verifying that your connections are correct for

each channel, trim the lengths to keep them short. Avoid cutting leads

too short.

7. At the source-end of cables from mV devices:

- remove the drain wire and foil shield

- apply shrink wrap as an option