Spectrum Controls 1756sc-IF8u User Manual

Page 26

14

ControlLogix

™

Universal Analog Input Module

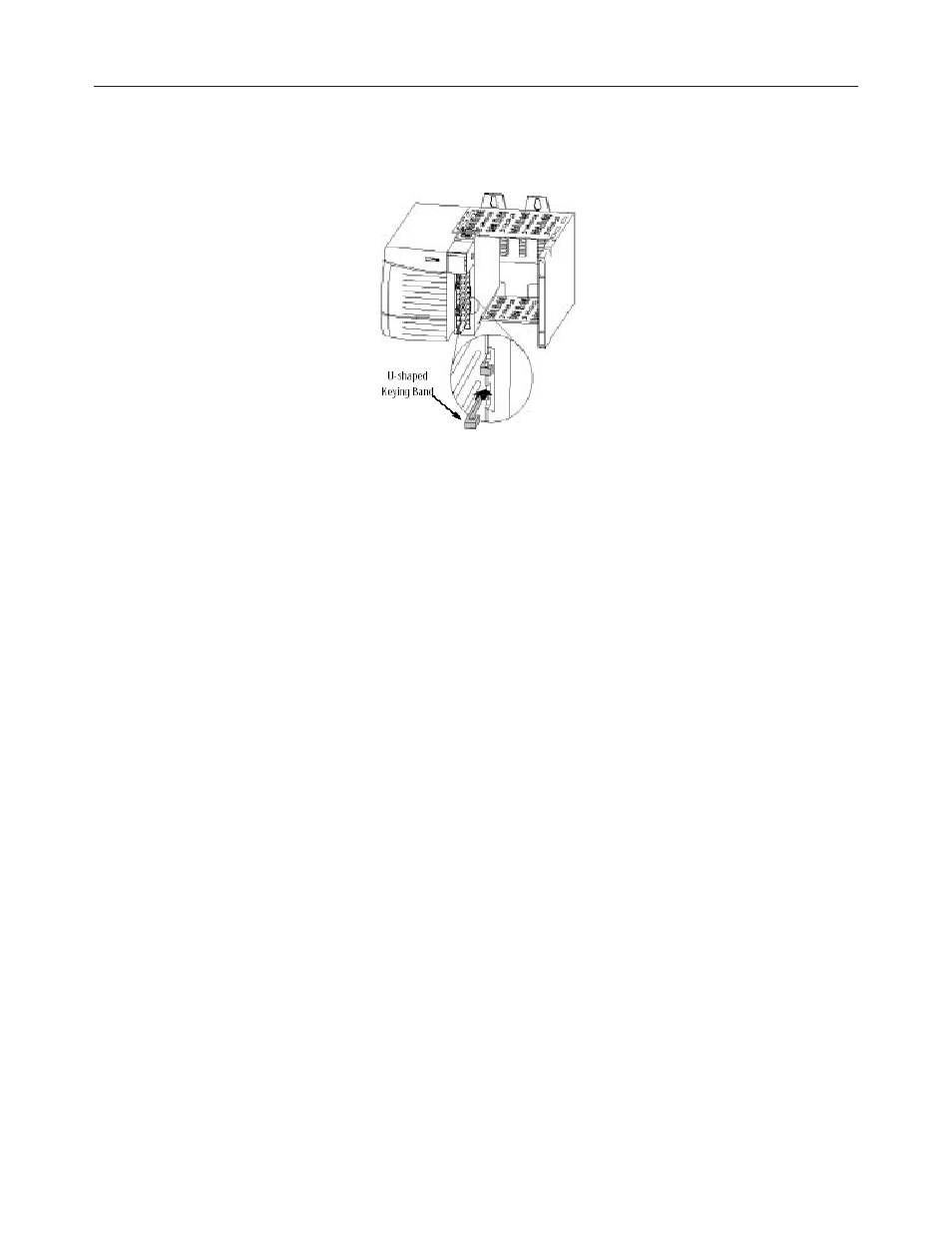

Figure 2.2.

Terminal block diagram with keying

Wiring Your Module

Follow these guidelines to wire your input signal cables:

• Power, input, and output (I/O) wiring must be in accordance with Class

I, Division 2 wiring methods [Article 501-4(b) of the National Electrical

Code, NFPA 70] and in accordance with the authority having

jurisdiction.

• Peripheral equipment must be suitable for the location in which it is

used.

• Route the field wiring away from any other wiring and as far as

possible from sources of electrical noise, such as motors, transformers,

contactors, and ac devices. As a general rule, allow at least 6 in.

(about 15.2 cm) of separation for every 120 V of power.

• Routing the field wiring in a grounded conduit can reduce electrical

noise further.

• If the field wiring must cross ac or power cables, ensure that they cross

at right angles.

• To limit the pickup of electrical noise, keep thermocouple, RTD,

millivolt, and milliamp signal wires as far from power and load lines as

possible.

• For improved immunity to electrical noise, use Belden 8761 (shielded,

twisted pair) or equivalent wire for millivolt sensors; or use shielded,

twisted pair thermocouple extension lead wire specified by the

thermocouple or RTD manufacturer. Using the incorrect type of

thermocouple extension wire or not following the correct polarity may

cause invalid readings.

• Ground the shield drain wire at only one end of the cable. The

preferred location is at the shield connections at the ControlLogix

chassis. (Refer to IEEE Std. 518, Section 6.4.2.7 or contact your sensor

manufacturer for additional details.)