SOR Single Point Ultrasonic Level Switch User Manual

Page 3

Form 829 (08.13) ©SOR Inc.

3/16

Sensor Installation

Notch-Type Sensor (Series 37

- N)

Series 370 Ultrasonic Level Sensors can be mounted by inserting the sensor through a

fitting in a vessel, or the sensor may be suspended over an open sump or basin.

Tank or Vessel

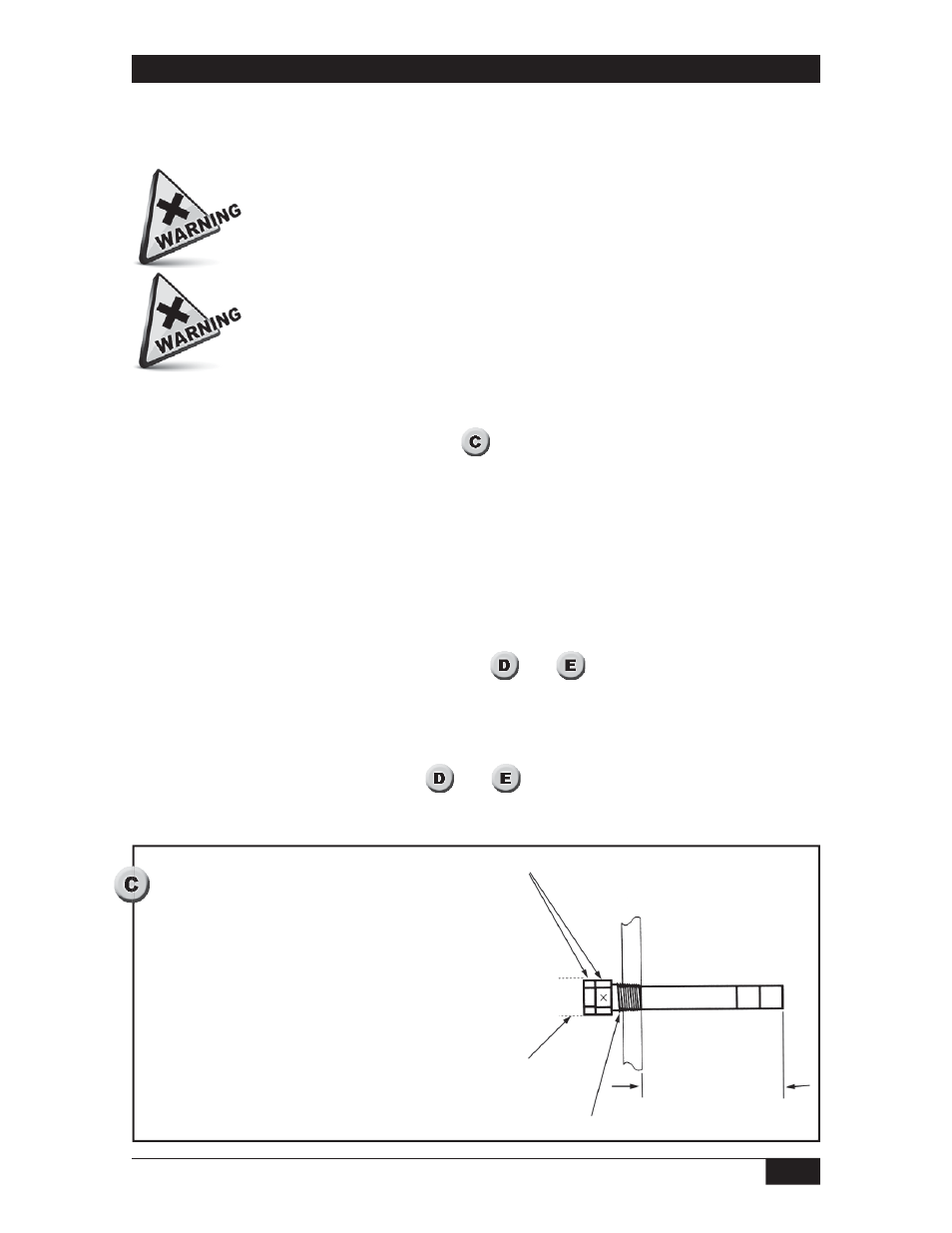

Make sure that the sensor can be fully inserted and tightened without interference from

obstructions inside the tank or vessel. (See

)

Apply suitable sealant to the process connection to prevent process leakage.

Do not use the sensor base as a handle to tighten the process connection.

One Point Horizontal Sensor Mounting (Series 371 Notch-Type)

When tightened securely, the sensor cavity must face sideways for optimum drainage when

process liquid level drops below the sensor cavity.

An alignment mark X stamped on a wrench flat (or on the dry face of a flange below the

housing) shows sensor cavity orientation. (See

(

and

y

)

Notch-Type Sensors — Optimum drainage occurs when the X mark is located at 3 or 9 o’clock.

The sensor must project through a tank fitting so that the sensor cavity is at least 1”

beyond the inner wall of the tank. (See

and

)

DO NOT weld any part of this instrument.

Irreparable damage may be done to Tefl on sensors by turning Metal hex

and Tefl on hex separately. Always rotate Metal hex and Tefl on hex

simultaneously. Do not apply more than 10 in. lbs. of torque to either hex

during installation!

Tefl on Notch Sensor

(Metal sensor may vary)

Always turn Teflon hex & Metal hex together

when installing sensor into process.

Sensor Base Hub

No Obstructions

Apply thread sealant