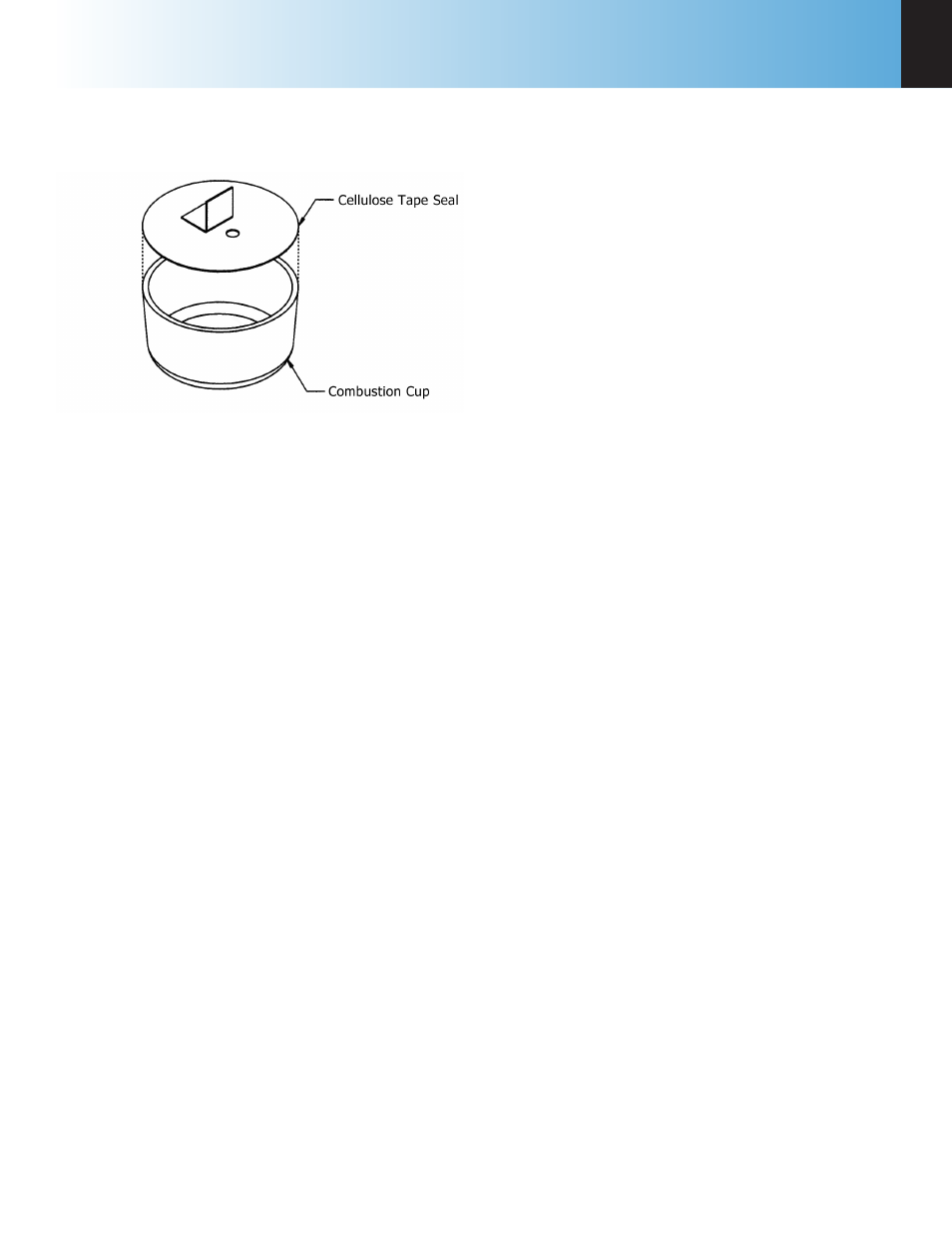

Poor combustion, Figure 5-7, Combustion capsule with adhesive tape seal – Parr Instrument 6200 User Manual

Page 27: Combustion capsule with adhesive tape seal 25, Operating instructions

Operating Instructions

6200

5

w w w . p a r r i n s t . c o m

25

Figure 5-7

Combustion Capsule with Adhesive Tape Seal

Use the following procedure when filling and han-

dling any of these tape-sealed sample holders:

• Weigh the empty cup or capsule; then cover the

top with tape, trim with a knife and press the

trimmed edge firmly against the metal rim. Also

cut and attach a small flag to the disc (see Figure

5-7).

• Puncture the tape at a point below the flag, then

re-weigh the empty cup with its tape cover.

• Add the sample with a hypodermic syringe;

close the opening with the flag and re-weigh the

filled cup.

• Set the cup in the capsule holder and arrange

the auxiliary fuse so that it touches the center of

the tape disc.

• Just before starting the test, prick the disc with

a sharp needle to make a small opening which

is needed to prevent collapse of the disc when

pressure is applied.

• Fill the bomb with the usual oxygen charging

pressure.

• The calorimeter will fire the bomb and complete

the test in the usual manner.

Volatile samples are defined as one with an initial

boiling point below 180 °C per ASTM D-2.

Low volatile samples with a high water content, such

as urine or blood, can be burned in an open capsule

by absorbing the liquid on filter paper pulp or by

adding a combustion aid, such as ethylene glycol.

Poor Combustion

Because of the difference in combustion char-

acteristics of the many different materials which

may be burned in an oxygen bomb, it is difficult to

give specific directions which will assure complete

combustions for all samples.

The following fundamental conditions should be

considered when burning samples:

• Some part of the sample must be heated to its

ignition temperature to start the combustion

and, in burning, it must liberate sufficient heat

to support its own combustion regardless of the

chilling effect of the adjacent metal parts.

• The combustion must produce sufficient tur-

bulence within the bomb to bring oxygen into

the fuel cup for burning the last traces of the

sample.

• Loose or powdery condition of the sample which

will permit unburned particles to be ejected dur-

ing a violent combustion.

• The use of a sample containing coarse particles

which will not burn readily. Coal particles which

are too large to pass a 60 mesh screen may not

burn completely.

• The use of a sample pellet which has been made

too hard or too soft. Either condition can cause

spalling and the ejection of unburned fragments.

• Insufficient space between the combustion cup

and the bottom of the bomb. The bottom of the

cup should always be at least one-half inch above

the bottom of the bomb or above the liquid level

in the bomb to prevent thermal quenching.

• Excessive moisture or non-combustible material

in the sample. If the moisture, ash and other non

combustible material in the sample amounts to

approximately 20% or more of the charge, it may

be difficult to obtain complete combustion. This

condition can be remedied by adding a small

amount of benzoic acid or other combustion aid.