Input voltages, Li and l2, Sec1 and sec2 – Bryant FA4A User Manual

Page 27: Y and c

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Á U G / 1 4 / 2 0 0 8 / T H U 0 3 : 5 1

UTC TECH PUB

ni

N o , 3 1 7 2 4 0 5 6 6 2

7 0 2 7

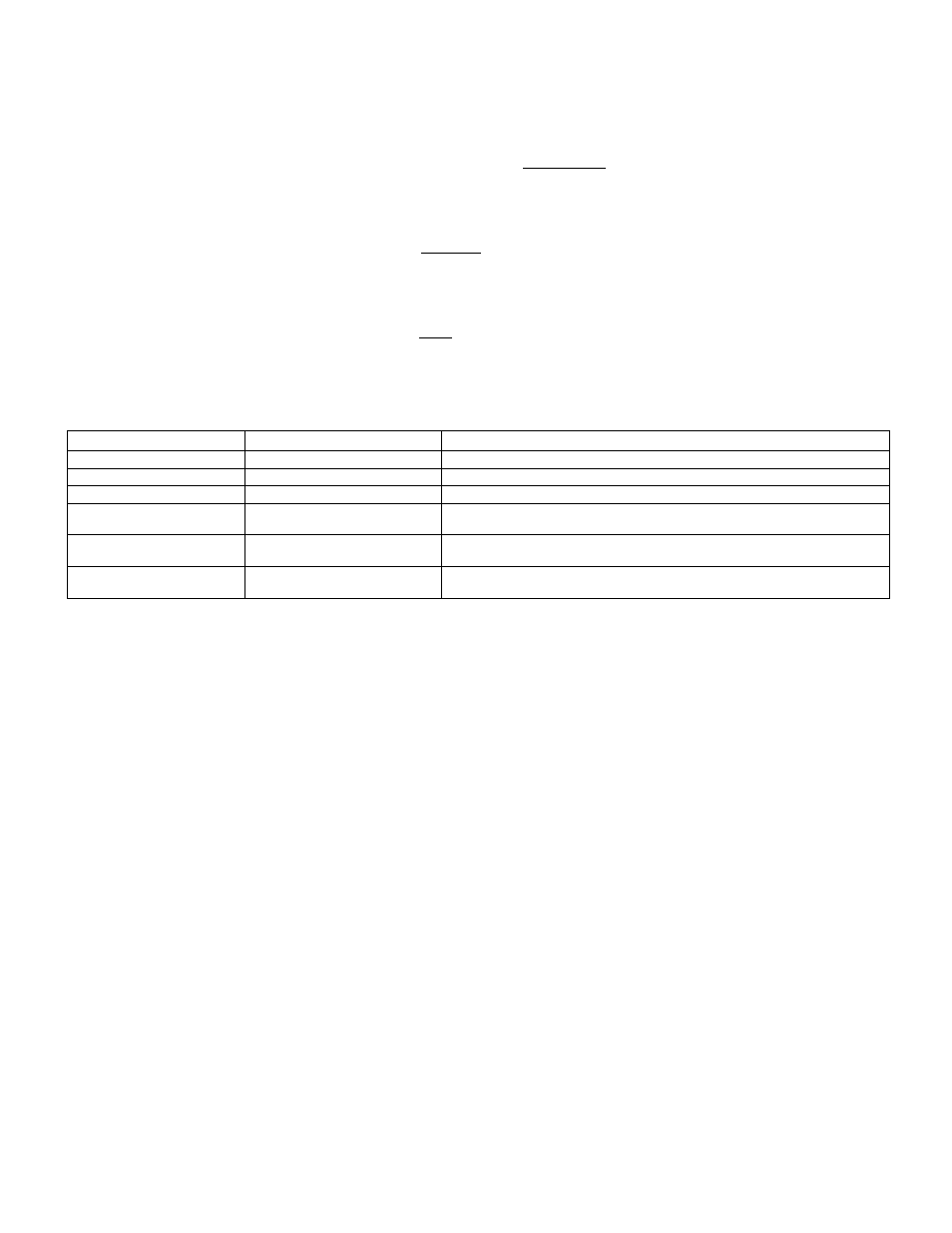

TABLE 9--TROUBL1ESHOOTING VOLTAGE READINGS AND TEST POINTS

INPUT VOLTAGES

LOCATION

NORMAL READING

PURPOSE

Li and L2

206/230 vac

Main power supply Input to fen coil.

L3 and L4

205/230 vac

Power to electric heaters

9-pin connsctpr

7 and 9

208/230 vac

Power to smart control

T1

and T3

206/230 vac

Power to transformer

SEC1 and SEC2

24 vac

Power from transformer secondary

n and C

24 Vac

•Power from transformer secondary

G

and C

24 vac

Call for continuous fan signal from room thermostat

Y and C

24 vac

Call for heat/cool signal from room thermostat

O and C

24 vac

Signal to energize reversing valve from room thermostat (cooling). Also present

during defrost,

___

W2T a n d C

24 vao

Call for eiectric heat from room thermostat

W2D and C

, .24 ,vac

Defrost initiation signal from heat pump

OUTPUT VOLTAGES

LOCATION

NORMAL READING

; ; PURPOSE

HI and F1

208/230 vac

Power to blower motor (high speed)

LO and.Fl

208/230 vac

Power to blower ,motor_(low speed)

and C '

24'vac

Power to energize contactor in heat pump (heat and cool modes)

’9-pin connactor

1 and 4

24 vdC

Power to energize SEQ 1

NOTE: Sequencers use DC voltage

9-pln connector

2 arid 4

24 vdc

Power to energize

SEQ

2

9-pln connector

3 and 4

24 vdc

Power to energize SEQ 3

Vac—

vetts

AC

vdD-^/oltS

DC

Thirty

Sec

after Y is energized,

control

energizes fan

motor.

It may

There is no hard and fast rule for detennining exactly when stages

run on high or low speedy depending on its operation in previous

cycle.

Compressor operation in current cycle is monitored by the smart

control to determine whether a fan speed change is required for

enhanced indoor comfort. The LED indicator on control signals 1

flash, indicating compressor operation only with no ejegtric heat.

The call for heat signals can be confirmed by placing voltmeter

leads across dow-‘voltag6 terminals Y, and C; The readings

should be 24v, -If 24v is not available, eheck the following:

■ Is 24v available across R and'C? See Rcady-To-Start section

for items to chedk if 24v is not available.

* Is thermostat function switch set in HEAT position with

theimostat calling for heat?

Assuming heat pump has power and is adequately charged, it

should be running at this time in heating mode. Indoor fan should

also be running at this time. H indoor fan is not mnniog, refer to ,

Continuous Ran section for items to check- When room thermostat

is satisfied, indoor fan continues to run an additional 60 sec to

recover heat remaining in indoor coil.

E. Heating (Compressor end Electric Heat)

If heat pump alone cannot satisfy heat requirements of structure,

room thermostat calls for additional heat by way of an input to W2

terminal of control. When this occurs, control begins sequencing

on electric heaters by energizing the first sequencer. Indoor fan

should be running at this time.

If room temperature requirements cannot be met, additional stages

of electric heat are energized through the other 2 sequencers, at 2.

The logic of control determines how much and bow soon these

additional stages are brought on. By observing LED status light,

the number of operating stages of electric heat can be determined.

The control also varies indoor fan speed depending on number of

energized stages of heat. In general, the more stages of electric

heat, the higher the fan speed.

will be energized since microprocessor in the smart control

constantly monitors duration of previous heating cycle, setting of

room thermostat, and number of stages of heat needed in previous

cycle to satisfy room thcmiostat. Rather than try to determine what

should be operating when, service technicians should check LED

status light to see how many stages of electric heat are energJKfid

at a given time and confirm operation of sequencer using a

voltmeter. If a quick check of all stages is desired, set room

thermostat as high as it will go. With a constant signal on W2T

terminal, sequencers energize every 10 minutes until all heaters are

on.

The previous paragraphs described how to' check for low-voltage

inputs to control by placing voltmeter leads across low-voltage

terminal strip and checking for 24v, The call for electric heat can

be confirmed by placing voltmeter leads across W2T and C.

To check for operation of" sequencers, check' directly across

appropriate sequencer coil for 24 volts DC,

NOTE: All sequencer coils are powered by 24 volts DC. This

voltage is generated internally by the smart control.

In this example, sequencer 1 is being checked. The procedure is

the same for all other sequencers. If 24 volts DC is not observed,

check the following;

* Is room thermostat calling for electric heat? This can be

confirmed by checking for 24 volts AC between low-voltage

terminal strip terminals W2T and C-

* Is LED flashing appropriate code for number of sequencers

energized? In this example, 2 flashes should be visible,

indicating 1 sequencer is energized. Indicator tells how many

sequencers are energized, but docs not tell which ones are.

' Is 9-pin connector for heater package tightly secured to

control board?

-

27

-