Ii. slope coil units – Bryant FA4A User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A U G / 1 4 / 2 0 0 8 / T H U 0 3 : 4 8

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

A902G8

Fig. l4"’A-Coil Component Lpç^tion

a. Attach jïiajiifüld/gage sfit to scrvict valves.

b. Front seat (dose) liquid tube service valve.

c. Start unit in cooling mode.

d. Run unit until vapor pressure reaches 5 psig (35kPa).

e. Turn off electrical supply to outdoor unit.

£ Front seat vapor service valve.

g, Recover any remalning .refrigerant.

NOTE: All outdoor unit coils will hold only factory-supplied

amount of refrigerant. Excess refrigerant;, such as in long-tube

applications, may cause compressor internal pressure relief valve

to open (indicated by sudden rise in vapor pressure) before vapor

pressure reaches 5 psig C35kPa), If this occurs, tiim riff electrical

supply to outdoor unit immediately, front seat vapor service valve,

and recover any remaining

refrigerant,

2. Turn off electrical supply to indoor unit.

3. Disconnect condensate drain tube,

4. Disconnect liquid and vapor tubes from indoor coil. Use a

tubing cutter to cut tubes.

NOTE; If a torch is used to unbrace tube set, protect fitting panel

with a wet cloth or braze shield, as necessary.

5. Remove coil access panel,

6. Remove clip securing fitting panel to condensate drain pan.

Remove fitting panel,

7. Remove any shipping dips, including horizontal pan clip,

and slide coil/condcnsatc pan assembly out of unit.

8. Upflow or Horizontal Applications Only—Remove hori

zontal condensate drain pan from coij/condensate pan

assembly. (See Fig. 14.)

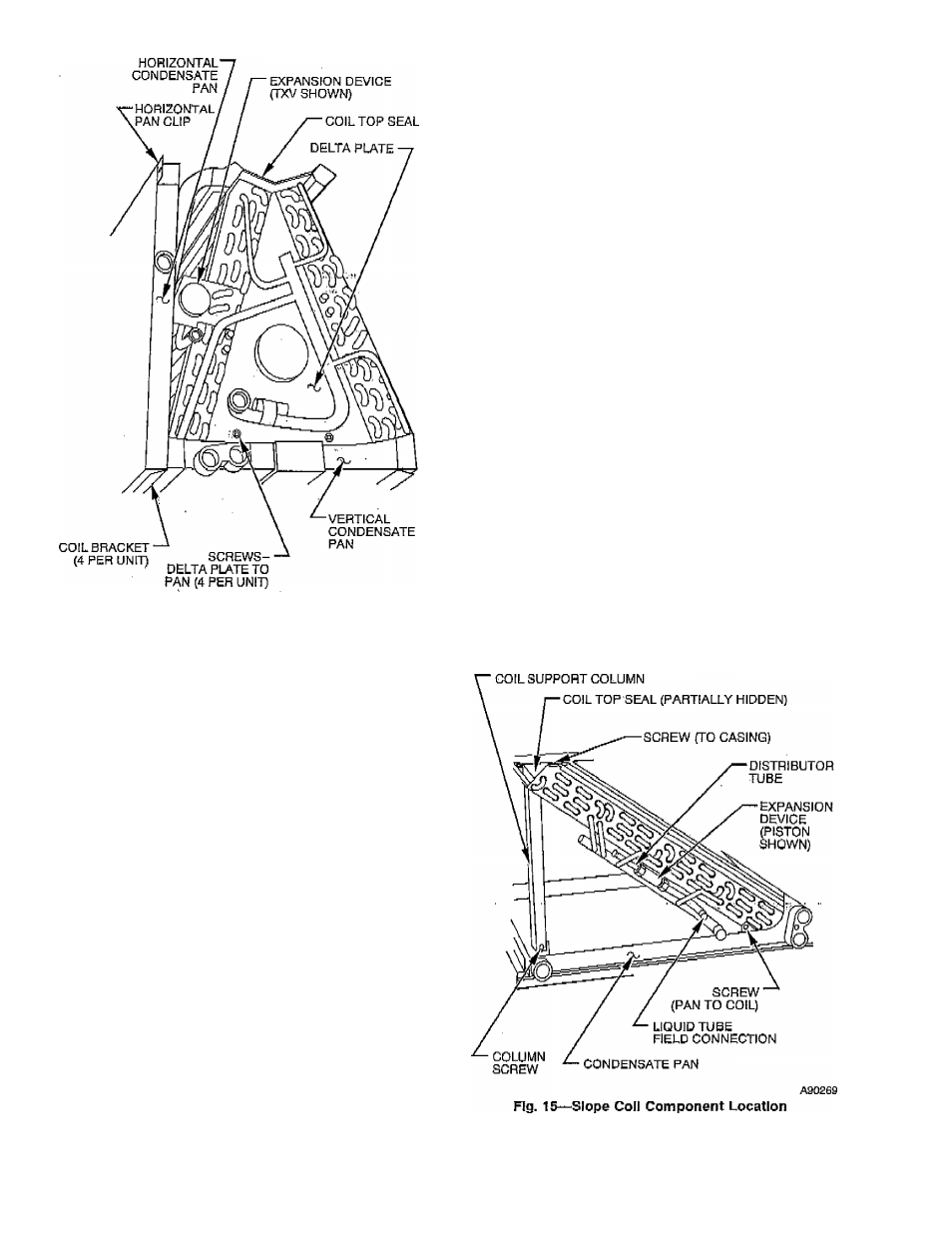

9- Remove 4 coil brackets. (See Fig. 14.)

10. Remove screws at delta plates and remove coil from vertical

condensate drain pan, (Sec Fig, 14,)

11.

Horizontal Applications Only—

Remove

coil top seal

(attached with, 4 screws) and J-shaped tube from original

coil and install it in same position on new coil. (See Fig,

14.)

12. Place coil assembly in plastic condensate pan and secure

using 4 screws through delta plate, (See Fig- ,14.)

13. Horizontal andUpflow Applications Only—Attach 4 coil

brackets to coil/pan assembly. (See Fig. 14.)

14.

Horizontal Applications only—Place horizontal conden

sate pan into position on coil/pan assembly,

NOTE: Installation of horizontal cemdenfiate pan is not necessary

for upflow or

downflow

applications,

15. Slide complete assembly into unit,

16. Reinstall fitting panel and reconnect clip securing fitting

pane] to condensate drain pan.

17. Horizontal Applleotions Only — Reinstall horizontal pan

clip. Secure with 1 screw. (See Fig. 14.)

18. Reinstall coil access panel.

19. Reconnect liquid and vapor refrigerant tubes, and conden

sate drain tube. Install Elter-drjer(s), if necessary.

20. Eyhcu^ate tube set and indoor coil, back seat (open) liquid

and vapor service valves.

21. Turn'bn electrical supplies to indoor and outdoor units.

22. Check system refrigerant charge and operation. See "Split-

System Residential Air Conditioners and Heat

Pumps

Service Manual" for further information,

II. SLOPE COIL UNITS .

If it is determined that system does not have leaks and refrigerant

is not contaminated, proceed as follows:

1. Recover system refrigerant.

16-