Fig. 21—checking pulley alignment and tightness, Ii, maintenance, A, return-air filter – Bryant FA4A User Manual

Page 24: B. coil, drain pan, and condensate drain, I. pcb component layout, description, and function

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A U G / 1 4 / 2 0 0 8 / T H U 0 3 : 5 1

UTC TECH PUB

:}

UNE

GROUNO

LEAD

A91151

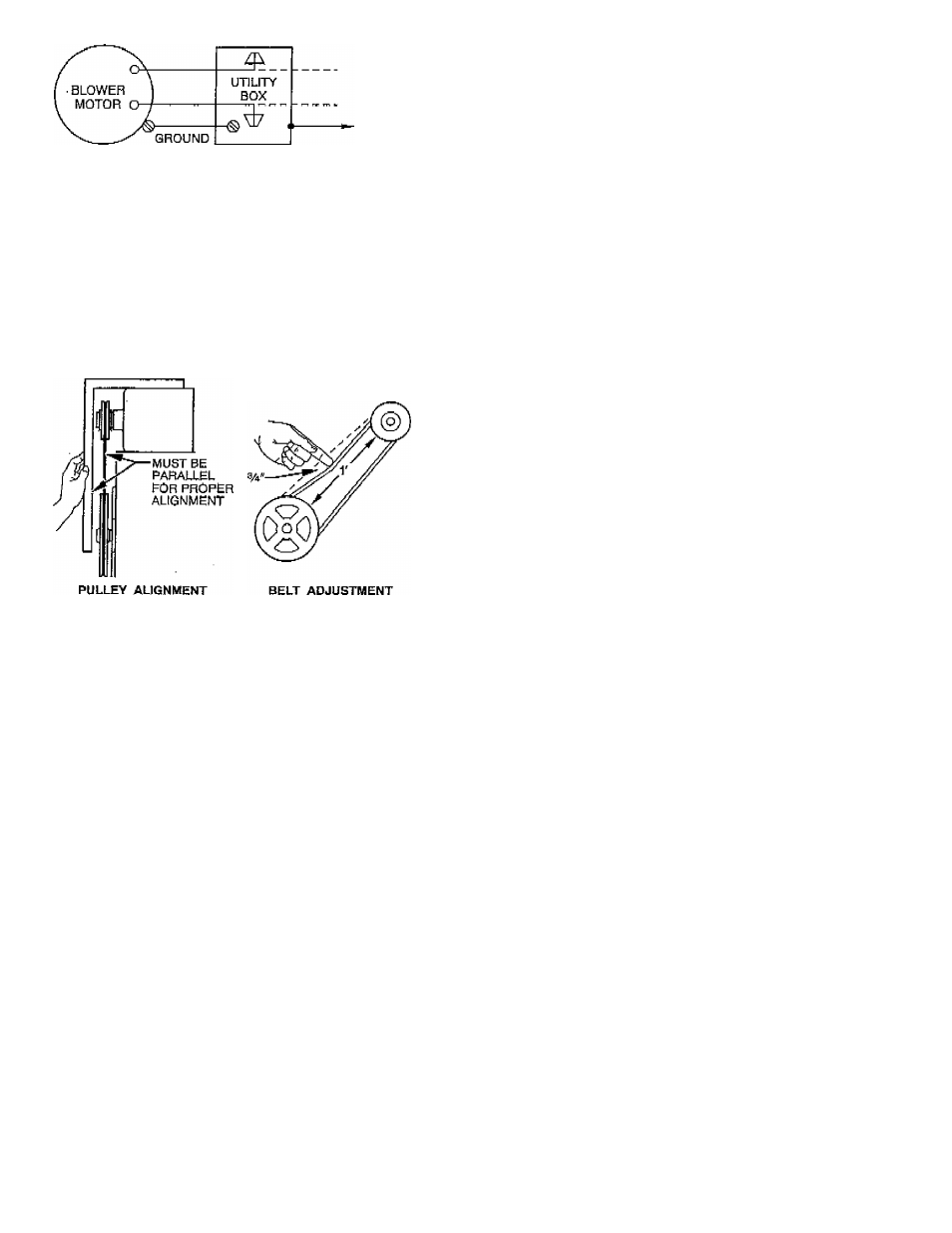

Fig. 20—Wiring Schematic

firmly. Lock adjusting bolt in position after adjustment is made.

Align pulley grooves by locating motpr pujley on motor shaft or by

moving entire motor along motor mounting bracket. Adjust blower

speed by loosening setscrew in outer (moveable) pulley face and

turning this face (half or full turns) so that adjusting setscrew is

positioned precisely over the flat on pulley hub. Speed is reduced

by adjusting pulley faces so they are further apart; speeds is

increased with faces closer together. Cheek pulley setscrews and

bolts.

A91150

Fig. 21—Checking Pulley Alignment and Tightness

D. Cleaning or Replacing Refrigerant Flow-Control

Device

Refer to Fig. 19 and instructions given in FD3A Service and

Troubleshooting section above,

II, MAINTENANCE

A

A

WARNING: Disconnect electrical power to all circuits

before servicing unit. Failure to do SO may result in

personal injury from dcctrical shock or moving parts.

WARNING:

As with any mechamcaj equipment, per

sonal injury can result fi'om sharp metal edges. Be careful

when removing parts.

A, Return-Air Filter

To clean or replace sir filter, remove screws and filter access door.

Slide out filter. For washable type filters, clean with hot soapy

water. Rinse clean and let dry.

New filters are available from a local distributor. Place filter in slot

with filter arrow facing direction of airflow. Replace filter access

doors with screws previously removed.

A

CAUTION:

Never operate unit without a filter or with

filter access door removed. Damage to blower motor may

result-

B. Coil, Drain Pan, and Condensate Drain

F A X N o , 3 1 7 2 4 0 5 6 6 2

A

CAUTION:

Discounect electrical power before remov

ing any access panels or electrical shock may result.

The coil is easily cleaned when dry. To check or clean coil, remove

coil access panel. If coil is coated with dirt or lint, vacuum with a

soft brush attachment.

Be careful not to bend fins. If coil is coated with oil or grease, it

may be cleaned with mild detergent and water solution. Rinse coil

with dean water. Be carciiil not to splash water on insulation or

filter.

Check drain pan and condensate.drain at same time cooling, coil is

checked. Clean drain pan and condensate drain by removing any

foreign matter from pan. Check for rust and holes. Flush pan and

drain tube- with clear water. If drain is restricted, clean with

high-pressure water. If this does not work.

Use

a plumbery's snake

or similar probe device. Rcpitch drain pan to promote proper

drainage.

FA4A, FB4A. AND FC4B SMART HEAT CIRCUIT BOARD

FUNCTION AND TROUBLESHOOTING

I. PCB COMPONENT LAYOUT, DESCRIPTION, AND

FUNCTION

NOTE:

All voltages are AC unless otherwise specified.

1. The low-voltage terminal board is used to coimeot indoor

thermostat to low, 24-v side of transformer and to serve as

a junction between indoor thermostat and outdoor seefion.

a, R terminal is used to connect secondary side of trans

former to thermostat and outdoor unit. R is fused.

b. C terminal is used to connect transformer secondary

common for thermostat and outdoor unit.

c, Y terminal provides input signal from thermostat signal

ing heat pump operation,

d. G terminal provitJes input signal from thermostat signal

ing cdnUiiiiOus fan 'dperatidn,

c,

O terminal provides input and junction terminal for

reversing vaive sign'd.

f, W2D terminal provides input from outdoor unit (heat

pump) signaling control board that heat pump is in

defrost.

g. W2T terminal provides input from thermostat signaling

for supplemental or emergency heat.

h. W3 terminal provides input from outdoor thermostat.

W3 and W2T are factory connected by JWl. Thl^ input

is used only if an outdoor thermostat is required by local

codes.

i, Y(, rerinihar provides output from control board to

energize outdoor unit (heat pump) contactor.

2. Jumper wires (JWl and JW2). (See Fig. 22.)

a. JWl connects W2T to W3 to limit staging of electric

heat with use of an outdoor thermostat. See Table 7 for

staging. Smart Heat PCB controls staging to the extent

that this feature is unnecessary unless required by local

codes

Or

regulations.

b. Cutting JW2 sets Smart Heat PCB in efficiency mods.

With JW2 cut, there is no loss of performance due to

reduced indoor blower speed when heat pump is oper

ating near balance point. This jumper may need to be cut

if selected cooling fan speed is the same as required

minimum motor LO speed tap selection. With JW2 cut,

fan terminal LO becomes a dummy terminal.

-

24

-