V. liquid tube strainer, V. care and maintenance, A. motor – Bryant FA4A User Manual

Page 23: Utc tech pub, Device

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A U G / 1 4 / 2 0 0 8 / T H D 0 3 : 5 0

UTC TECH PUB

F A X N o . 3 1 7 2 4 0 5 6 6 2

P . 0 2 3

n

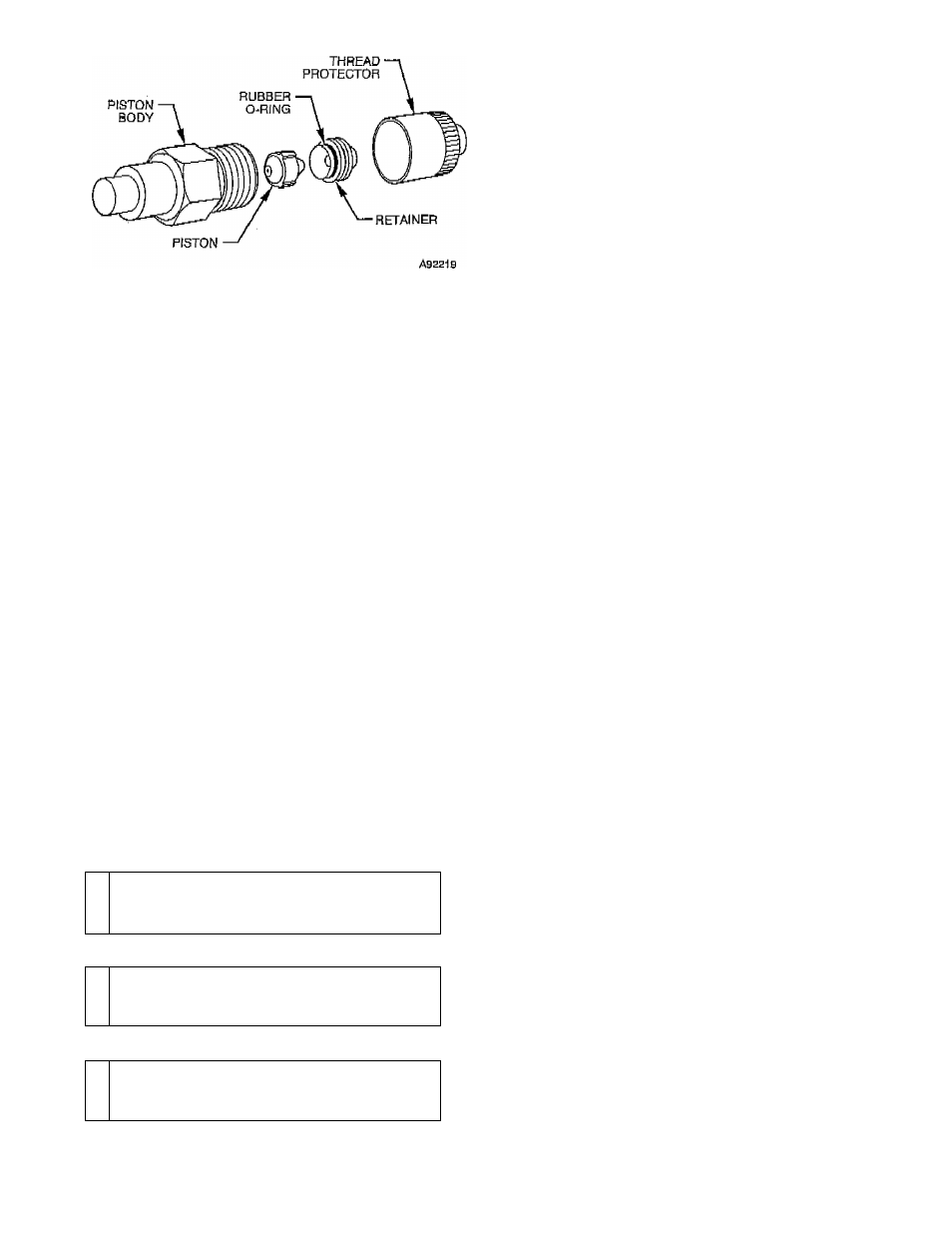

Fig, 19—Refrigerant Flow-Control Device

(For FD3A and FG3A)

A

CAUTION:

Use a backup wrench and do not over

tighten as deformation of refrigerant flow-control device

body will occur, causing piston to lodge in a partially

Open Or

closed position.

6. Install new or cleaned piston in refrigerant flow-control

device body.

7. Install new retainer (because of probable damage which

occurred in initial remov&J)-

8. Reconnect refrigerant tube to refrigerant flow-cOntroI de

vice.

9. Pressurize tubing and coil, then leak-check.

10. Evacuate tubing and cojl as necessary.

)V. LIQUID TUBE STRAINER

The refrigerant flow-coittrol device .is.

protected

on indoor coil by

a wire mesh strainer. If strainer becomes plugged:

1. Complete items 1 and 2 under Cleaning or Replacing

Refrigerant Flow-Control Device section.

2.

Loosen flare fitting joint connecting refrigerant flow-

control device to coil liquid refrigerant tube.

3. Remove sheet metal screw holding bracket clip in place,

Screw is located between coil and refrigerant flow-control

device,

4. Pull bracket clip out.

5. Remove refrigerant flow-control device assembly,

6. Pull strainer out of coil liquid refrigerant tube and replace

with new strainer,

V. CARE AND MAINTENANCE

A

WARNING:

Hinged access panel contains electrical

components and is heavy. Support panel when lowering

to clean unit to avoid personal injury.

A

WARNING:

Disconnect electrical power to all circuits

before servicing unit. Failure to do so may result in

personal injury from electrical shock ox movingiparts.

A

WARNING:

As with any mechanical equipment, per

sonal injuXy can result from sharp metal edges. Be careful

when removing parts.

The minimum maintenance requirements for this equipment arc as

follows:

1. Inspect and dean or replace field-supplied air filter each

month or as

required.

2. Inspect cooling coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean as necessary. (To be

performed by trained personnel.)

3.

Inspect blower motor and wheel for cleanliness each

heating and cooling season. Clean as necessary,

4. Inspect electrical connections for tightness and controls for

proper operation each heating and cooling season. Service

as necessary,

NOTE:

Never operate without a Alter or with hinged access door

Open,

Damage to blower motor may result.

A. Cooling Coll, Drain

Pan,

and Condeneata

Drain

Remember to disconnect electrical power before opening hinged

access panel.

The cooling coil ig easily cleaned when dry. Inspect coil and clean

(if necessary) before e&ch cooling season. If coil inlet face is

coated with dirt or lint, vacuum with a soft brush attachment.

Be careful not to bend coil flns. If coil is coated with oil or grease,

clean it with a mild detergent-and-hot water solution. Rinse coil

with olear water. Be careful not to splash water onto insulation.

Inspectidrain pan and condensate drain at same time cooling coil

is checked. Clean drain pan and condensate drain by removing any

foreign matter from pan. Fliish pan and drain tube with dear water.

Clear drain line ifrresfricted.

NOTE:

There MUST be a trap in condensate line. Trap must be

at least 3-in. deep, not higher than the bottom of unit condensate

drain opening, and pitched downward to an open drain or sump.

B. Blower Motor and Wheel

Clean blower motor and wheel when cooling coil is deaned.

Lubricate , motor every 5 years if motor is used on-intermittent

opefafidn (thermostat FAN switch at AUTO position);, or every 2

years if motor is in continuous operation (thermostat FAN switch

at ON position). Remove motor to lubricate. Put approximately 8

drops of SÁE 10 nondetergent oil in each oil hole. Do not bveroil

motor. Plug hole securely so that oil does not drip when hinged

access panel is lowered'to 'open position.

Blower motor and wheel may be cleaned using a vacuum with a

soft brush attachment. Remove grtaae with a mild solvent such as

hot water and detergent. Be careful not to disturb balance weights

(dips) on blower

wheel

vanes. Do not drop or bend wheel as

balance will be affeefed.

FG3A

service

and

TROUBLESHOOTING

1. SERVICE

A. Motor

......................

Ball bearing oilers are provided on blower motor. Use electric

motor oil 6r SAE

lp

or'20 nondetergent oil. Check motor mount

bracket and''Í3ás¿ bolte. Tighten as required.

B. Blower

Check ball bearings for wear. Ball bearings are self-aligning and

grease packed. Replace as required. Check thrust collars for end

play and alignment of wheel. Check blades for accumulation of.

dirt.

Clean as

required.

Check mounting brackets, base bolts, and

isolation material.

See Fig, 20 for diagram of internal wiring for blower coil

assembly. Control box (standard 4-in. junction box) is mounted on

refrigerant connection side of unit. All leads pass through strain

relief where they

enter

Control box. Wiring inside cabinet is

located so it does not come in contact with moving parts or sharp

edges,

C. Pulley and Belts

Check beJt tension and pulley alignment. (See Fig, 21,) Belt

tension is adjusted by motor tailpiece bolt, A deflection of about

3/4 in. to 1 in, per foot of span should be obtained by pressing belt

-

23

-